Westford, MA, USA – Zuken USA, Inc., and Vitech, a Zuken Company, today announced the industry’s first model-based wire harness design process as part of its digital engineering initiative. The new process fills the design gap that previously required the manual translation of the product model into schematics and spreadsheets to begin implementation. This manual effort can take weeks and breaks any direct connection between the model and the development process, making the ROI of a model-based design process almost impossible to measure. Zuken’s new E3.GENESYS Connector directly connects the product model to the wire harness design process, saving significant time and maximizing ROI.

Accelerating Digital Engineering Adoption

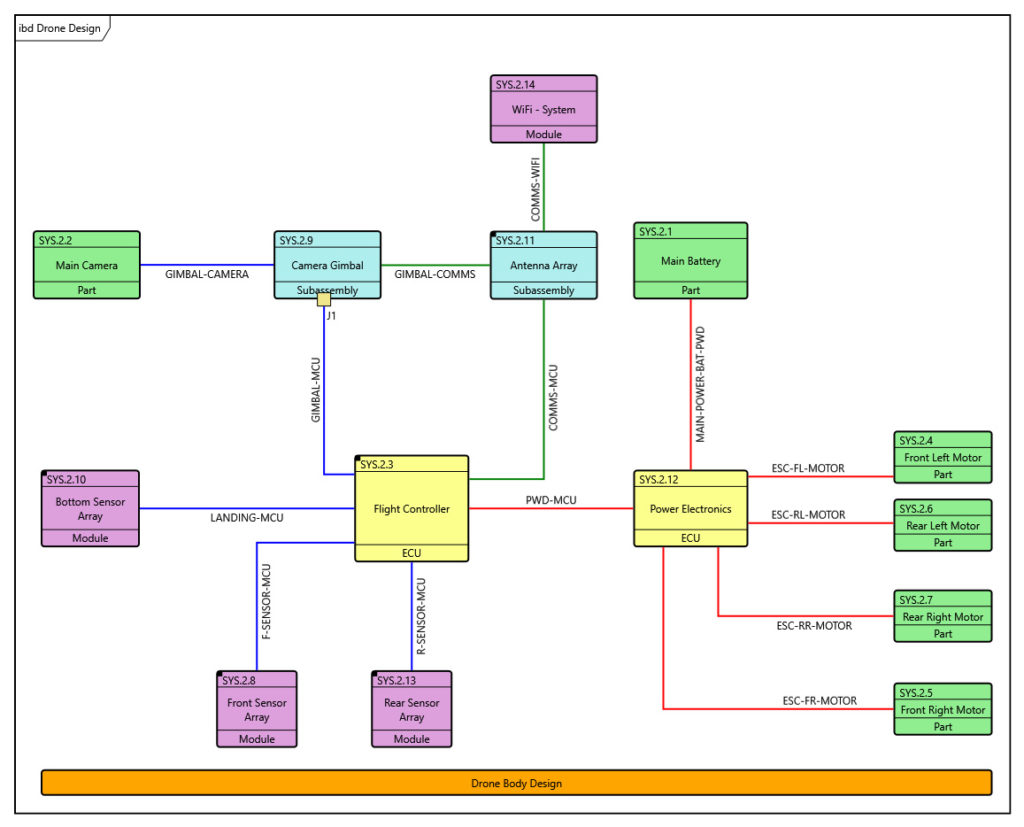

As product complexity increases, digital engineering methods offer numerous benefits over document-based processes. The model-based approach replaces design specification documents with a product model. A product model is a more rigorous way of describing a product than an unrelated assortment of documents, spreadsheets, and diagrams. A key benefit of the model-based approach is the elimination of design errors due to the relational nature of the product specification.

“An essential part of the digital transformation is the adoption of digital engineering methodologies to improve product development. With this new product, Zuken has successfully filled the design gap for model-based wire harness design,” said Kent McLeroth, President of Zuken USA Inc. “Zuken’s process innovation will accelerate the adoption of digital engineering beyond the mil/aero segment and into the broader market. We will continue to invest and be a leader in the digital engineering space.”

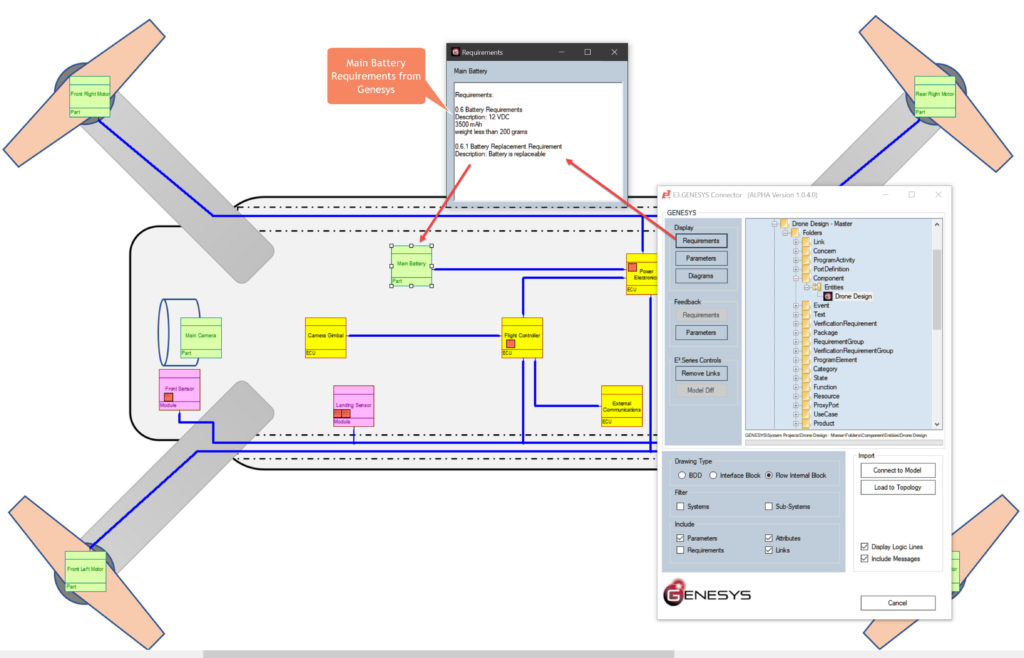

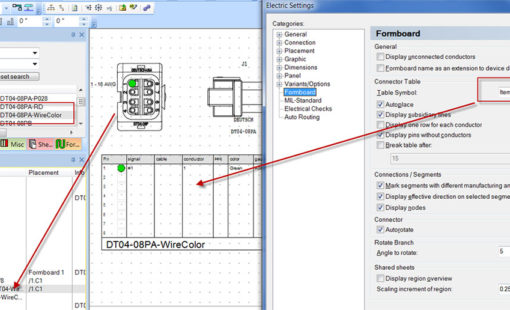

E3.GENESYS Connector eliminates the need to translate the model into design documents by directly connecting the model to E3.series for wire harness design. The wire harness design team using E3.GENESYS Connector transfers the specific subsystem or component of interest and exposes the requirements, diagrams, and constraints directly within the E3.series design environment. The product model becomes connected to the detailed design making it possible for companies to maximize the benefits of digital engineering.

“Zuken’s recent acquisition of Vitech enabled this level of innovation and collaboration,” said David Long, President of Vitech, a Zuken Company. “Combining our systems engineering and MBSE knowledge with Zuken’s electrical and electronic design expertise has made this first-to-market solution possible. We look forward to further advancing the deployment and value of digital engineering.”

Replacing Manual Translation with a Direct Connection

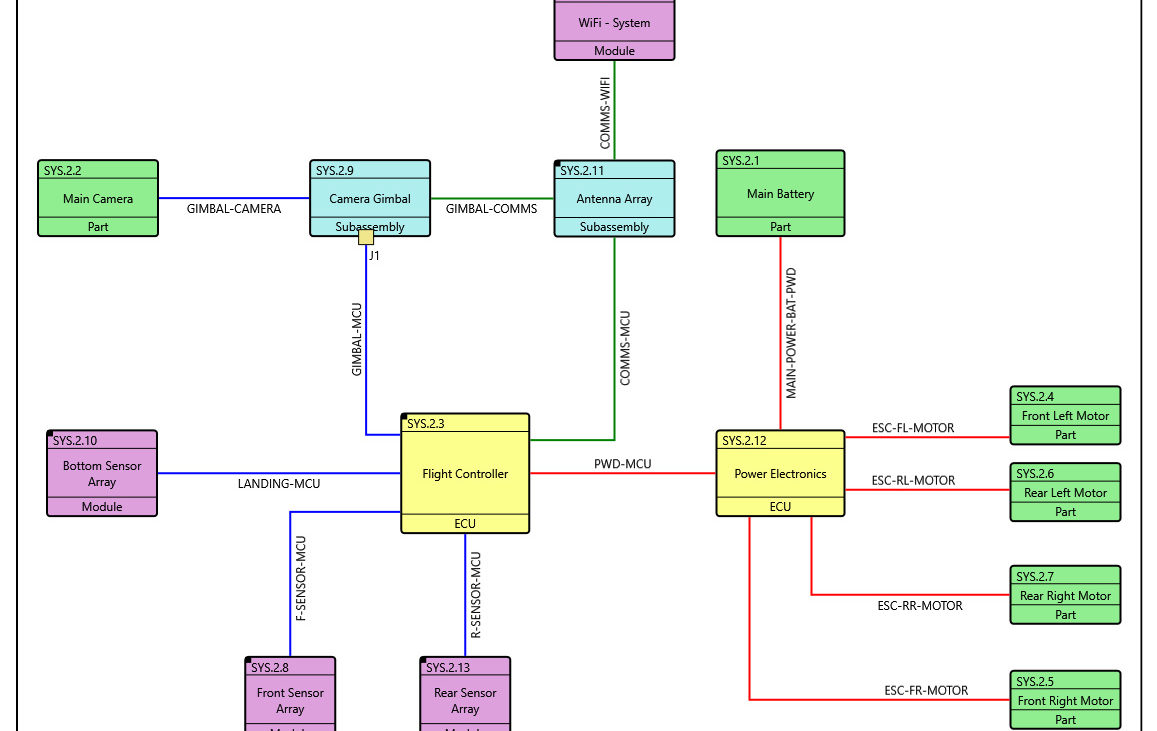

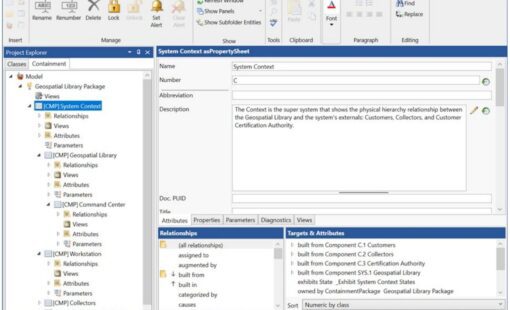

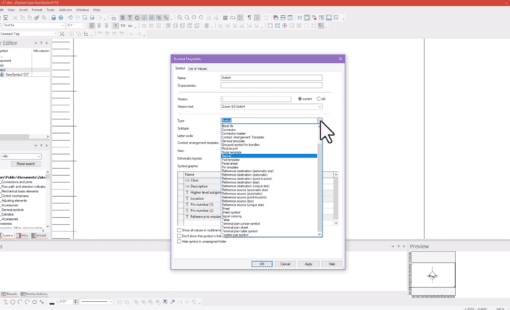

Vitech’s GENESYS is an industry-leading MBSE solution providing robust product model development capability. The product model comes with electrical and electronic schema extensions for creating the implementation design envelopes for subsystems and components. The design envelope provides the parameters, structure, and requirements needed to guide the implementation teams. E3.GENESYS Connector transfers and exposes the design envelope from GENESYS to E3.series, eliminating manual design translation.

Maintaining Model and Product Consistency

A product model disconnected from the product lifecycle raises the risk of divergence between the model and the implementation. The result is a product that may not perform as initially defined. Once the model is in development, it must remain relevant and active throughout the product lifecycle. E3.GENESYS Connector preserves that connection.

E3.GENESYS Connector is available now. To learn more, visit Digital Engineering for Product Development.

Related Resources

- 2020 Technical Webinars

In this webinar, we will introduce all the new functionality for 2020 Harness Builder for E3.series and summarize some of the more important existing functions in the tool.

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.