“We are now creating more right-the-first-time designs and one of the biggest benefits is being able to reduce the number of decoupling capacitors, which adds up to a significant reduction in manufacturing costs.” TEWS is now looking forward to increasing its use of Power Integrity Advance’s virtual prototyping capabilities in its next design projects.

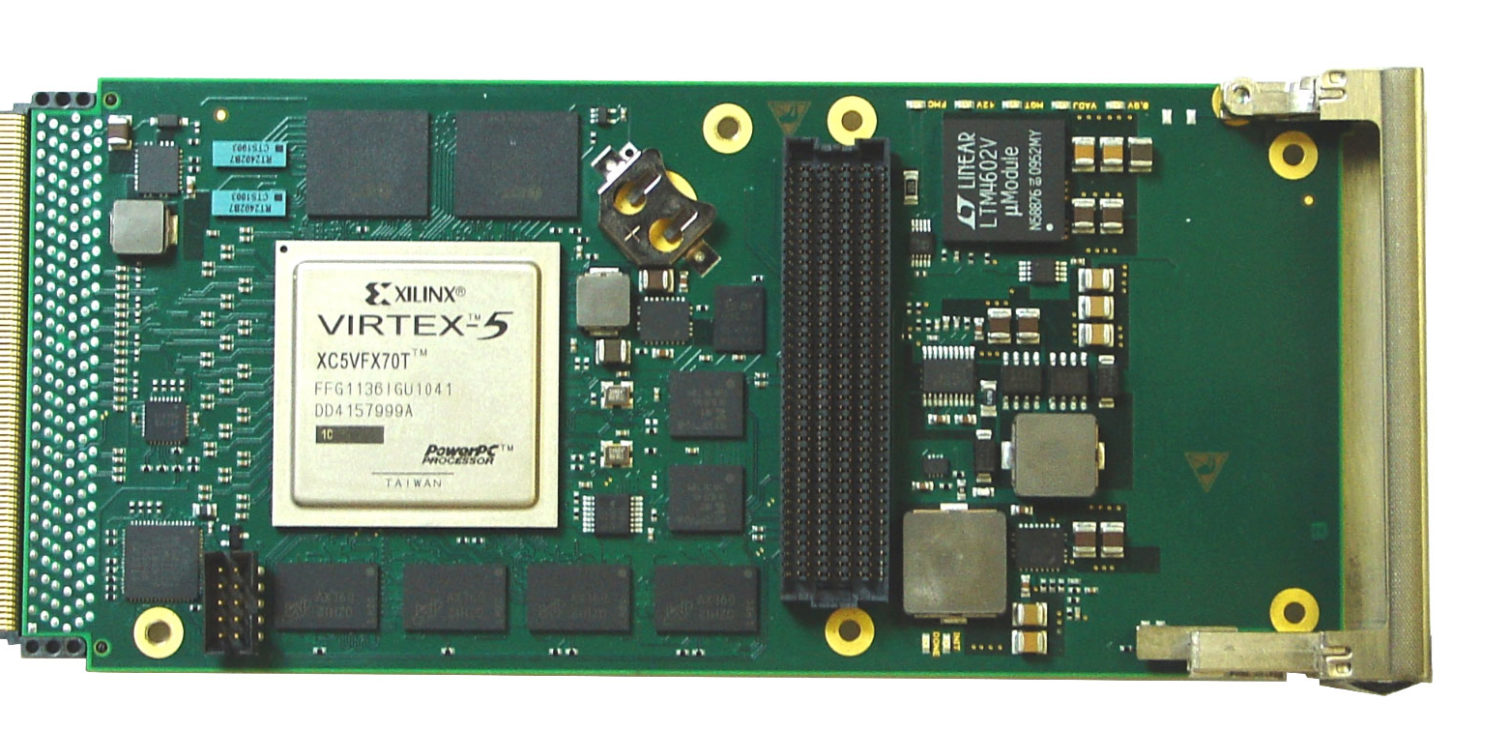

TEWS Technologies encountered challenges around power distribution on PCBs for their embedded interface modules, due to today’s increasingly complex designs. By adding CADSTAR Power Integrity Advance module to their high-speed design flow they are now meeting targets for right-the-first time designs and achieve rapid compliance with power integrity constraints.

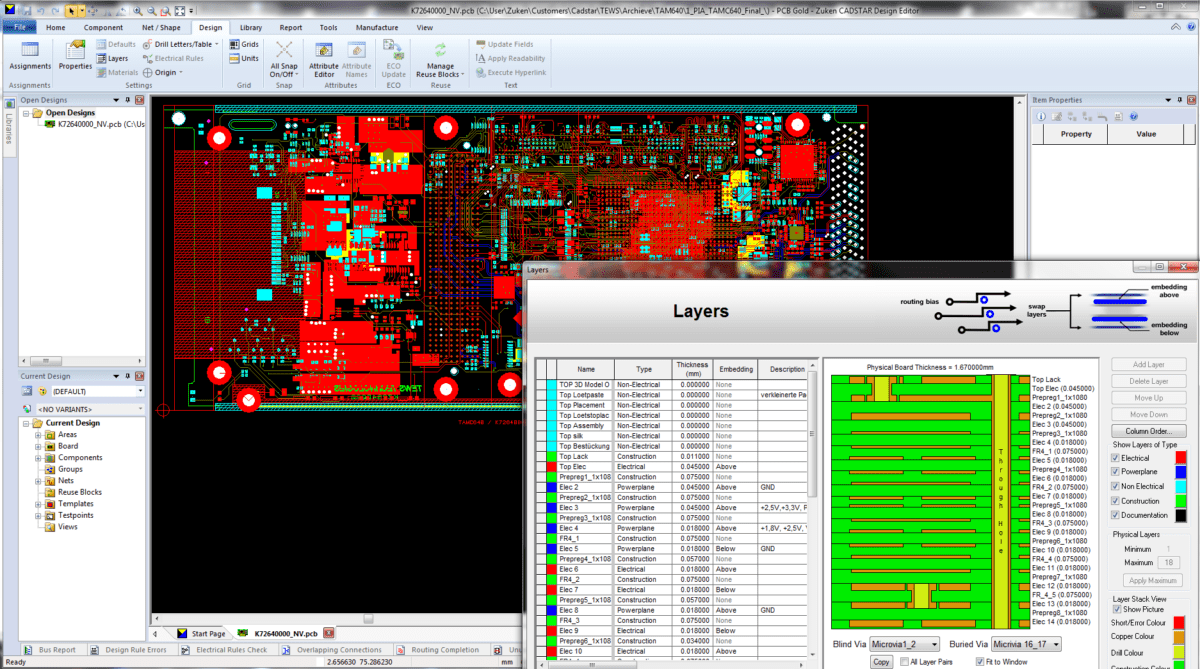

Following a benchmarking study, TEWS made the decision to add the CADSTAR Power-Integrity Advance module to their sophisticated high-speed design flow to address design problems around power distribution on their PCBs.

Results

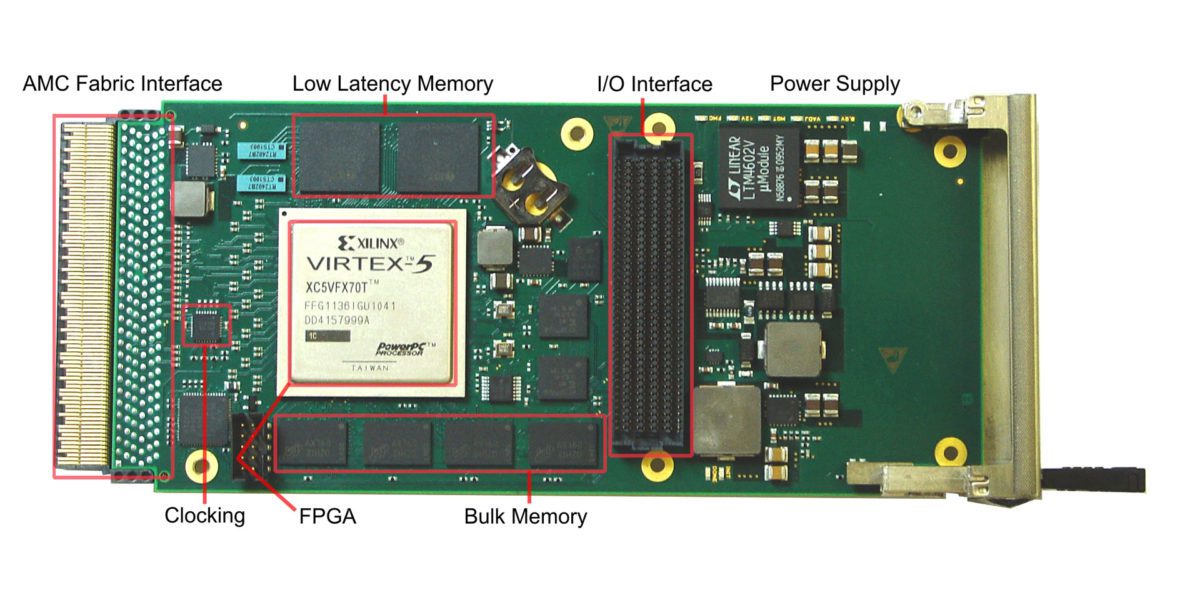

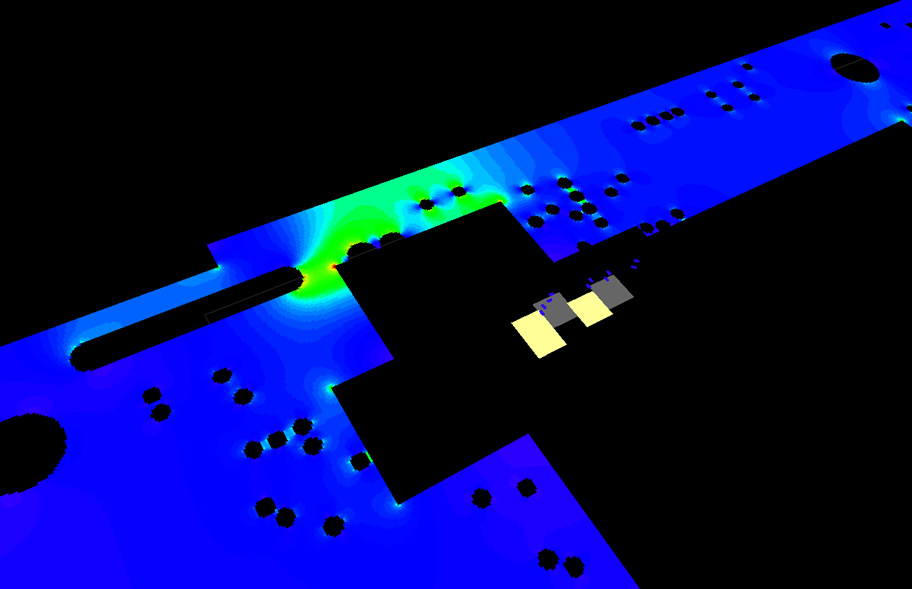

Due to its high internal quality standards, TEWS was eager to verify the accuracy of the Zuken approach from the outset. For signal integrity they compared the simulation and impedance results with measurements performed by their board manufacturers. Then they compared the Power Integrity Advance analysis results with analytical attempts on specially designed structures. TEWS was pleased by the match between the simulation results and measurements and gained confidence in the power integrity simulation capabilities as well. “It is essential for us that correct signal routing and bus termination is guaranteed to ensure reliable operation. We also need to ensure that under our extremely high quality standards, with impedance controlled layer stack-ups and an impedance target of 55 Ohms, analysis results closely match PCB specifications for SI and Power Distribution Systems.”

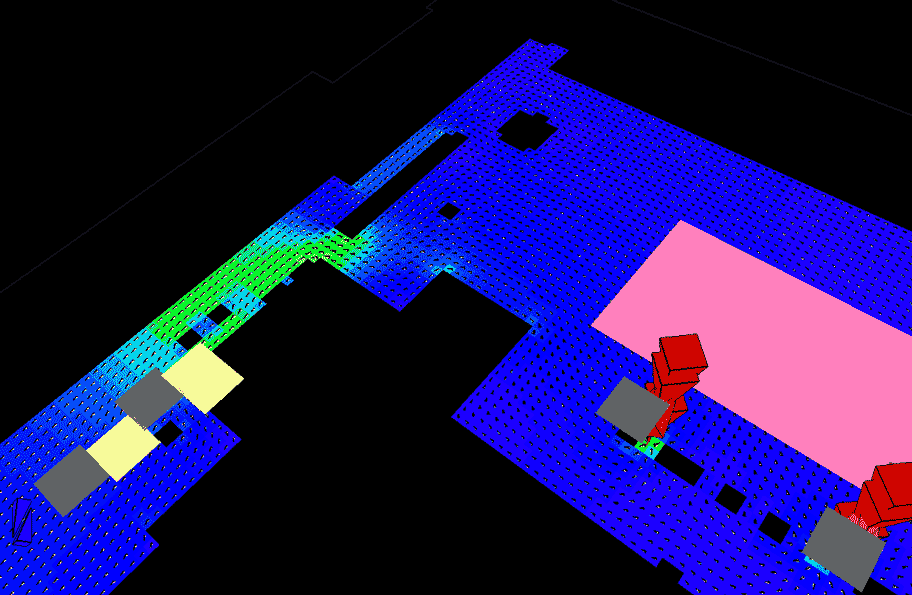

“We found the Zuken SI Verify and Power Integrity Advance tools quick and easy to use from the outset.” Zuken’s integrated Signal Integrity and Power Integrity analysis modules offer a more streamlined alternative: the engineer invokes the simulator from the PCB CAD tool, works on selected elements, or even the entire design, makes design changes and immediately re-analyzes the results. “This is a much higher level of integration than has previously been possible with third-party analysis solutions. It lets us integrate analysis very early in the design process; a capability that is becoming increasingly critical to a design project’s success”. With power integrity analysis linked directly to the CADSTAR constraint-based PCB design process, the design can be re-simulated during or after each layout step to ensure no problems have been introduced.

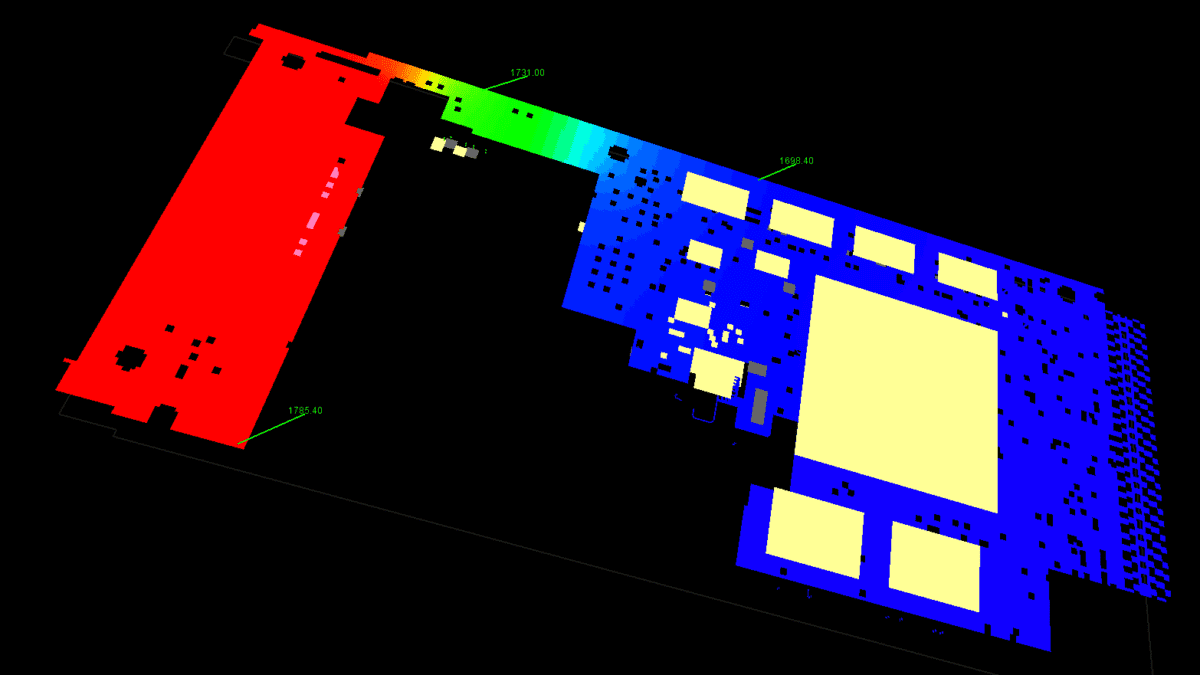

TEWS soon realized that they were able to try different decoupling schemes, layer spacing and power distribution area layout schemes using “what-if” capabilities in a fast and efficient way. As TEWS supplies products to international markets, EMI and EMC compliance are also critical. This requirement was satisfied by using the EMI module within the Power Integrity Advance toolset, using algorithms developed at Missouri University of Science and Technology (formerly the University of Missouri-Rolla), to predict the worst-case emission levels of a PCB. “Even though we did not expect to match chamber measurement with accurate dBs, the ease-of-use and reliability of the results of Power-Integrity Advance EMI, together with its fast analysis, gave us important hints about radiation hot spots on the board well before we produced the first prototype.”

Related products

Discover more about the products that helped Renishaw