DC Bottleneck Inspection: Improving Power Delivery in CR-8000 Design Force

Reliable power delivery is critical for every modern PCB and IC package design. As power rails get tighter and designs pack in more functionality, even a single high-resistance path in the power delivery network (PDN) can cause IR drop, noise, or thermal issues. DC Bottleneck Inspection in CR-8000 Design Force helps design teams find these weak spots early and fix them before fabrication.

What Is DC Bottleneck Inspection?

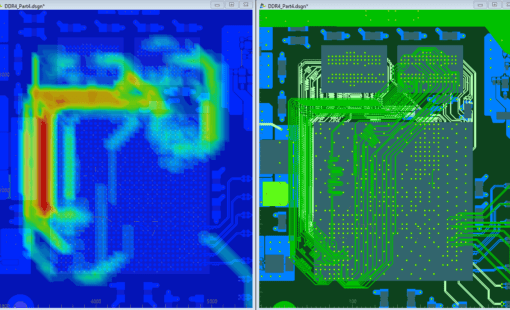

DC Bottleneck Inspection is an analysis method used within Design Force to detect narrow areas or tracks that increase resistance between a power source and its load. The tool calculates pin-to-pin DC resistance across the PDN and highlights paths where resistance is significantly higher than expected. These “bottlenecks” are often caused by narrow traces, excessive via transitions, or congested routing. Instead of manually tracing the PDN and guessing where problems might occur, designers can rely on DC Bottleneck Inspection to quickly show which current paths deserve attention.

How DC Bottleneck Inspection Works in Design Force

- The tool calculates pin-to-pin DC resistance between source and load pins across the PDN.

- It identifies pin combinations with unusually large resistance values that deviate from design expectations.

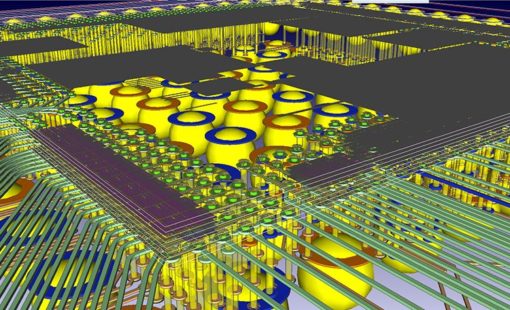

- These results are shown graphically on the Design Force canvas, so engineers can:

- Spot narrow traces, high-resistance neck-downs, and via bottlenecks at a glance.

- See how routing choices and copper shapes affect power delivery.

- Relate resistance spikes directly to layout features instead of abstract numbers.

Because the analysis runs directly in the layout environment, it fits naturally into an existing CR-8000 design and verification flow.

Key Benefits for Design Teams

-

Visual feedback: Bottlenecks are highlighted on the physical layout, making

it easy to see which areas block current flow. -

Faster debugging: Engineers no longer have to inspect the entire PDN by eye;

the analysis points directly to suspect areas. -

Improved reliability: Reducing unnecessary resistance supports cleaner power

delivery and helps control IR drop and voltage variation. -

Design optimization before fabrication: Layout changes can be validated early,

which reduces re-spins and shortens project schedules.

When used together with the power integrity capabilities in Design Force, DC Bottleneck Inspection becomes part of a broader approach to PDN analysis. For a deeper look at power integrity workflows, see the blog post Tech Tip: CR-8000 Power Integrity Analysis.

Who Benefits from DC Bottleneck Inspection?

-

PCB Layout Engineers

- Why it helps: Flags layout-induced resistance issues that are easy to miss visually.

- Benefit: Enables early design adjustments to trace widths, via count, and copper shapes to avoid costly rework.

-

Signal and Power Integrity Engineers

- Why it helps: Supports clean power delivery by reducing unexpected IR drop in key rails.

- Benefit: Improves the accuracy of PI simulations and validation runs based on realistic PDN paths.

-

Hardware Validation & Test Engineers

- Why it helps: Links unexpected voltage drops or thermal hotspots to specific layout features in the PDN.

- Benefit: Speeds up root cause analysis during bring-up and failure analysis, with direct visual guidance in the layout.

See DC Bottleneck Inspection in Action

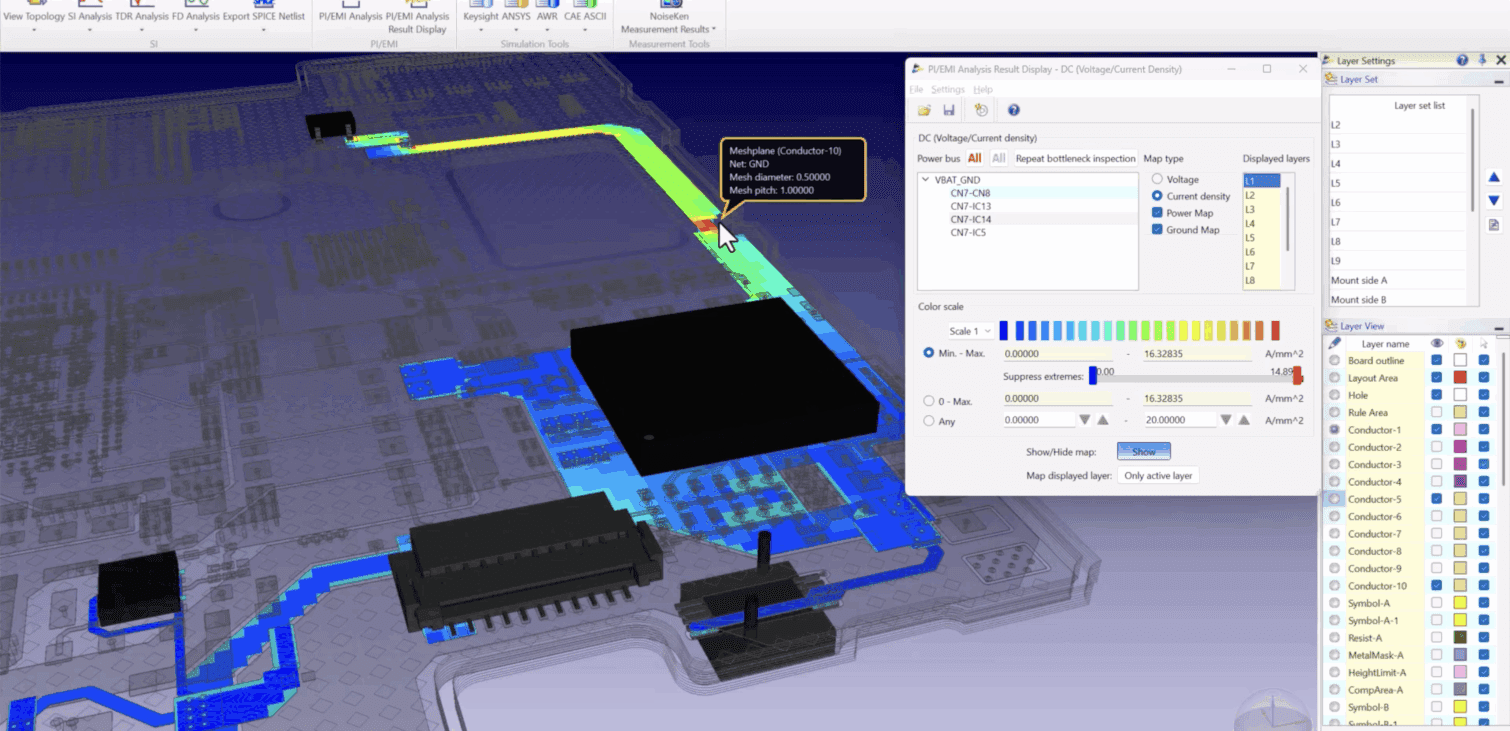

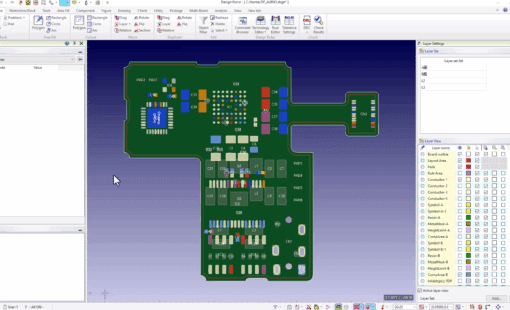

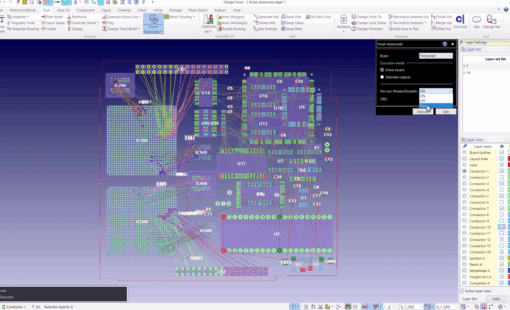

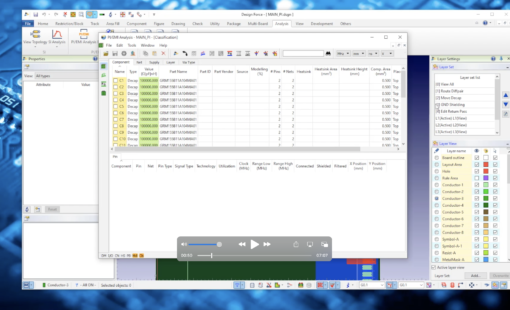

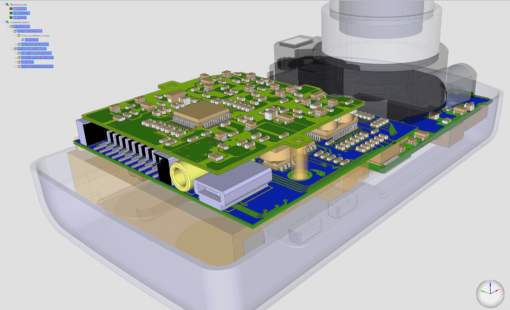

The following example shows how DC Bottleneck Inspection highlights high-resistance paths and maps them back to the Design Force layout:

Next Steps: Strengthen Your PDN with CR-8000

DC Bottleneck Inspection is one part of a broader analysis toolbox in CR-8000 Design Force. Combined with power integrity, signal integrity, and system-level analysis, it helps teams design robust PDNs that support today’s high-speed, high-density products. To learn more about how Design Force supports advanced PCB and IC package design, visit the CR-8000 Design Force product page or explore related articles such as System-Level PCB Analysis: Managing Complexity in Electronic Systems. For organizations looking to harden their PDN strategy, these tools and techniques provide a clear path from layout insight to measurable reliability gains.