This is part one of a three-part series exploring modular design. In this post, we explore the Engineer-to-Order approach to platform-based design.

Engineer-to-Order products meet customer demands through customization. While cars or cell phones come with a pre-set array of options and tell prospective buyers to choose, other products require more tailored offerings. In industries like rail, aerospace, and factory automation, the team starts with customer specifications and builds from there.

Some companies must implement the Engineer-to-Order approach because they build one-off solutions. Once a factory automation firm builds one candy production plant, it will never build an identical one. Other companies adopt this strategy as a market differentiator. A new agricultural vehicle company may differentiate itself from established brands by allowing the farmer to define exactly what they need instead of foisting an existing tractor line not designed for the farmer’s specific crop.

Starting the design process from the customer’s needs instead of a predefined catalog opens an intimidating world of seemingly limitless possibilities. Fortunately, the customer picked you due to your prior expertise. Design reuse is therefore possible, even if the train, airplane, or factory isn’t exactly the same as what you’ve designed before. By starting with a standardized platform and developing modular units, you can engineer customized products that efficiently meet niche demand.

Platform-Based Design

The platform-based design methodology starts with a core product backbone that accommodates all variations. For example, a train’s core product backbone would include the structural chassis, propulsion system, and critical electronics, designed with standardized interfaces to plug in various anticipated additions. When a transit agency selects its preferences, the engineering team assembles the configuration by integrating appropriate modules into the standardized interfaces.

Designing a platform requires significant upfront planning. Determining which system components remain consistent across variations depends on market factors and engineering practicality. Companies that employ the Engineer-to-Order approach often have multiple platforms; a car company will have separate platforms for sedans and trucks. The more you can keep in common within a platform, the faster your future design cycles.

Use Modular Blocks Compatible with the Platform

Modules are the configurable pieces of the product line that perform a specific function, like an infotainment system for a car or a camera on a drone. If you wanted to upgrade the drone’s capabilities from 1080P to 4K, you wouldn’t want to scrap the old design altogether. Instead, you’d swap out the old camera with a new one.

But it’s not that simple. The camera isn’t plug-and-play; the camera module includes an upgraded processor and additional wiring. After integrating the module, you still need to ensure that weight and power changes don’t significantly impact flight performance. Next, the process repeats. The engineering team would configure modular blocks for the drone’s battery, communications, and flight subsystems to create the many variations of the product line necessary to meet market niches.

Platform-based design only works if you can easily integrate modules into the platform. Typically, modules are subsystems engineered to fit into a specific interface to the core platform. As long as the interface supports all modules, it works like a charm. For example, consider your home office setup. Your computer is the core platform, and the monitors are modules. It doesn’t matter what monitor you pick; they all connect through the standardized HDMI port on your computer. In the worst case, an adapter is required, but it does the job. However, while a monitor adapter costs $20, integrating a complex subsystem that doesn’t fit into standardized interfaces could take weeks of engineering.

Fortunately, finding or creating modules that easily integrate into the core product backbone isn’t as challenging as it seems. In some industries, industry standards facilitate straightforward integration. For example, industrial automation uses rail-mounted PLCs, circuit breakers, and terminal blocks. It’d be difficult if the mounting slot sizes varied by manufacturer. Fortunately, American vendors have agreed on the TS35 standard, so the slot size of 35mm is nearly universal.

Without an industry standard, the platform defines the design envelope for subsystems. The Engineer-to-Order approach often involves creating new modules to fulfill customer requests. For example, if a defense contractor needs to modernize navigation capabilities on F-35s, they will design new avionics units to plug into the original interfaces. The old boxes restrict the space and interfaces that the new units must fit.

Even if a company relies on outside vendors for modules, that OEM can indirectly enforce the module’s design parameters. For example, a big-3 American car manufacturer may decide that their collision avoidance system will carry signals via a CAN bus network. This requirement naturally leads companies that supply sensors, cameras, and control units to support CAN bus. Whether designing modular blocks internally or externally, thoughtful planning maximizes the savings from platform-based design.

Zuken’s Solution for Engineer-to-Order

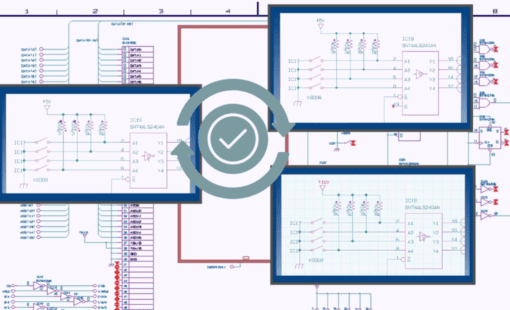

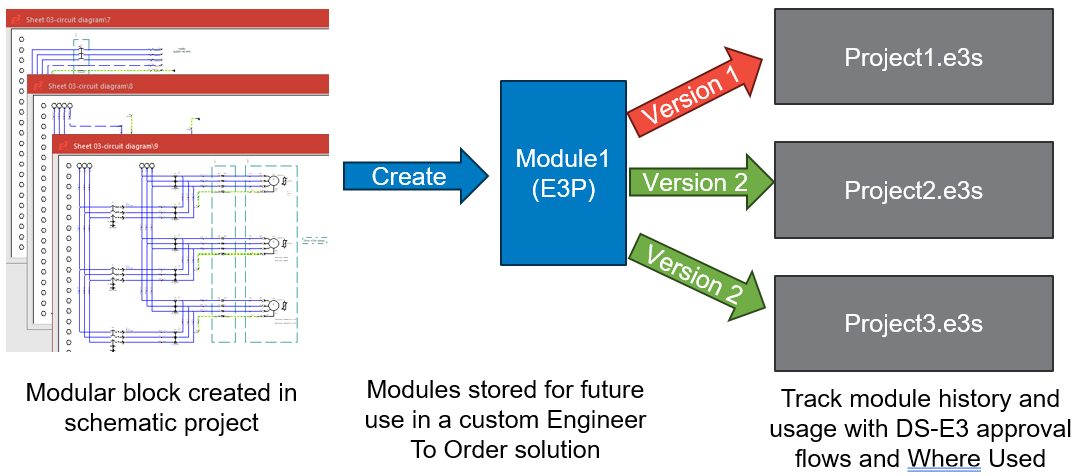

Zuken’s E3.series supports platform-based design. Engineers can save modules in a central database repository as subcircuits. These subcircuits can be as simple as a sensor assembly or as complex as an entire subsystem. Recent developments to support modular design mean E3.series can save connectivity within a subsystem and assign a part number, making tasks like bringing in a module as simple as drag-and-dropping into a project.

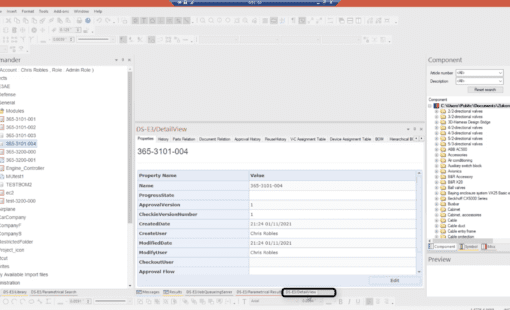

A digital thread tracks the usage of platforms and modules across projects. The platform can be version-controlled as the core backbone matures over time. Zuken’s DS-E3 tracks when a module is inserted into a project, the version of the module, and allows the user to see a history of that module across projects. This functionality enables engineers to leverage past designs and make informed decisions to create the next bespoke solution.

Engineer-to-Order has design challenges, but is necessary to create products that meet unique and specific demands. As the product evolves, a platform-based approach supports configurability over time. Digital engineering is key to implementing platform-based design that maximizes reuse with traceability.

Ready to take your Engineer-to-Order processes to the next level? Explore how Zuken’s tools for platform-based design can empower your team to engineer with precision, speed, and confidence.

Related Products and Resources

- Blog

- Blog

- Products

- Brochure