Feumotech manufactures highly specialized custom made fire trucks. Vehicles like these usually require immense development efforts. Using Zuken’s E3.series electrical engineering software, the Swiss manufacturer significantly reduced the development effort for each of its vehicles. At the same time, they were able to increase the quality of their electrical design documentation.

For more than thirty years, Feumotech has specialized in customized designs that customers appreciate for their ease of operation and reliability. One-off productions and small-batch sizes are not an exception, but rather the standard. Efficient and flexible engineering tools are, therefore, a vital element for Feumotech’s success.

“E3.series has a number of features that allow us to generate added value from our ECAD data. This benefits our logistics, manufacturing, and customer service.”

Daniel Bucher, head of control engineering at Feumotech

Complexity? Under control!

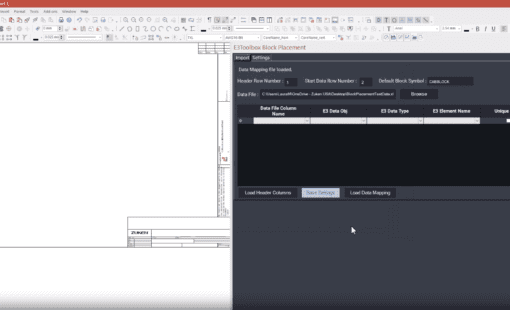

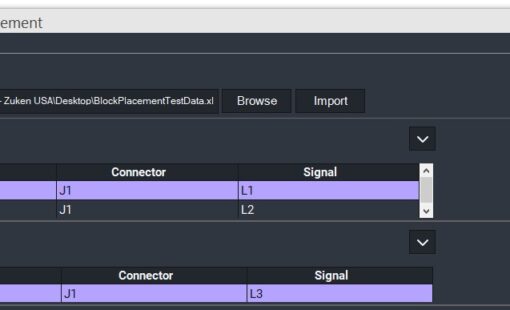

For several fire engines recently produced in a small series, engineers created various assembly designs from scratch. In addition, the end-users were able to select from different chassis configurations and a range of equipment options. Thanks to the options and variants functionality in E3.series, integrating the electrical equipment for the newly designed assemblies into the circuit diagram as subcircuits was a quick and easy task. Selecting vehicle-specific differences required only the push of a button.

With external manufacturers working on several new assemblies, it was necessary to build and test them as prototypes in advance. Consequently, the development time frame was overly ambitious. Also, part of the development and circuit diagram design had to take place at the home office. Due to the Covid-19 pandemic, Feumotech took strict measures to ensure the safety of its employees. Thanks to the efficient and flexible capabilities that E3.series offers, they managed to stick to the schedule despite the difficult circumstances. In some cases, customers took delivery of the vehicles before the initially planned delivery date.

Spaces tighter than the time frame

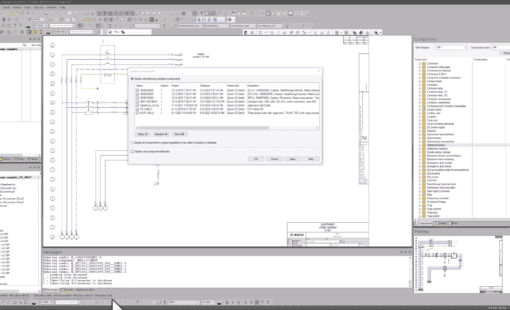

E3.series’ flexibility proved to be an advantage in another project where design engineers had to fit multiple systems into a tight space. In this instance, one complete system required several ICT systems, large screens, control panels, cameras, along with air conditioning systems.

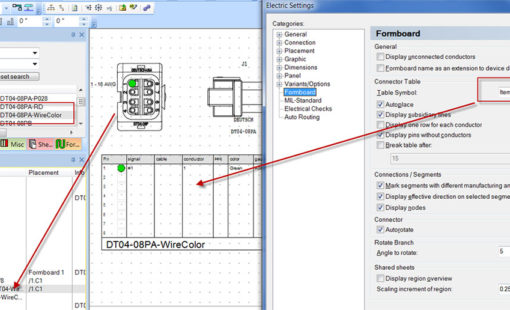

The challenge was to integrate the external suppliers’ subsystems and to document them accurately and concisely as one complete system. Numerous change requests surfaced during the design process, all requiring integration into the current project. The team integrated the externally engineered systems into the master wiring diagrams with minimal internal effort. And with the block functionality of E3.series, the engineers were able to keep the documentation process lean and always up-to-date.

Related Products and Resources

- Webinar

- Products

- Success Stories