Bruker is full of praise for Zuken. “Whenever we needed anything, they were always quick to help out. We are delighted with the support provided by Zuken. The same applies to the ongoing development of the system. Capabilities that we hoped for five years ago have now become reality.”

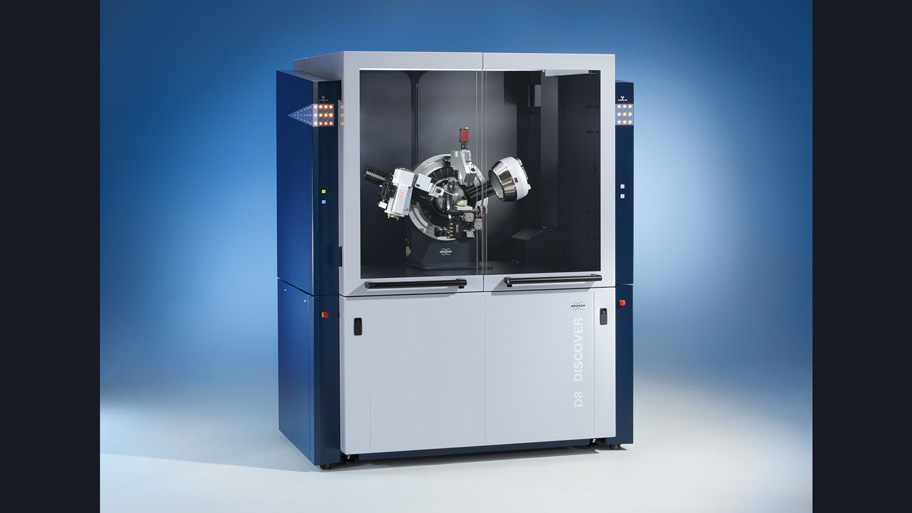

To improve the quality of its electrical documents such as wiring diagrams, and to raise its design efficiency, Bruker AXS GmbH Karlsruhe implemented Zuken’s E3.series at all stages. The manufacturer of X-ray analysis systems uses E3.series from concept and production to service.

X-ray analysis systems, such as those produced by Bruker AXS, are used for material investigations in labs, material research, and even industrial manufacturing control. “Bruker AXS is one of the world’s leading manufacturers of X-ray spectrometers for element and microanalysis, diffractometers for material analysis, and single-crystal diffractometers for analyzing chemical and biological molecular structures,” explains Jürgen Fink, head of the Electronics development department in Karlsruhe.

Results

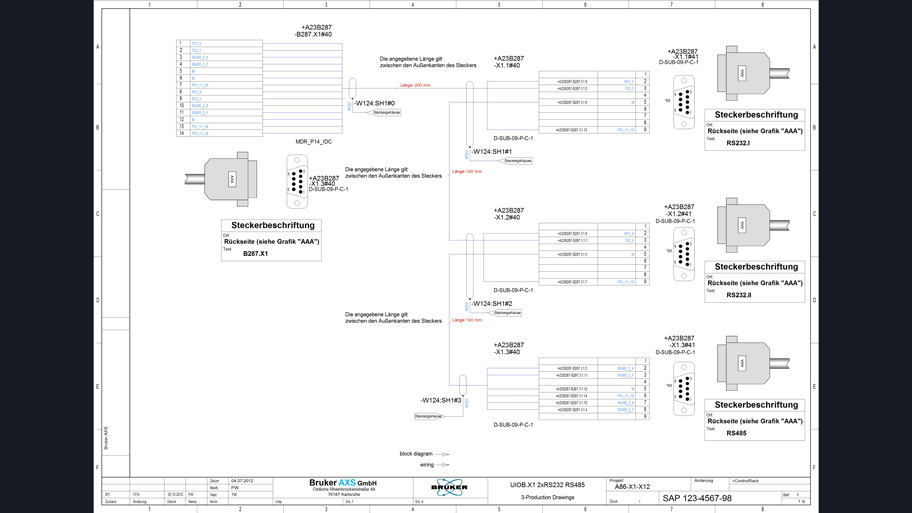

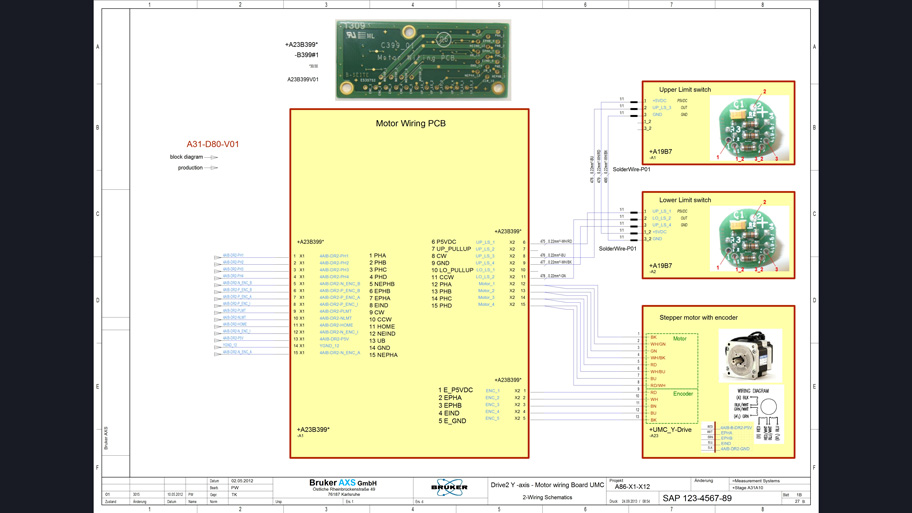

E3.series uses an object-oriented data structure and a common core. Data is transferred between the various modules, providing optimum user support throughout the entire design process, from development to production. This reduces errors, increases quality, and allows engineering changes to be completed much more effectively.

“We are now experiencing a noticeable increase in productivity because we have slashed the time it takes to develop the first sample or pre- series device. Manufacturing drawings for individual connection cables can be produced from the wiring drawings in a highly automated fashion.”

Compared with how employees used to work, the quality of wiring and manufacturing drawings has also vastly improved. This results in higher quality device cabling and means that fewer iteration stages are needed in the development phase. In addition to the benefits outlined above, E3.series has proven to be highly effective in analyzing device defects. The system allows individual signals to be easily tracked from the sensor/actuator through the wiring assemblies to the control electronics.

Related products

Discover more about the products that helped Bruker