Direct connection. E3.series becomes connected to GENESYS and the model.

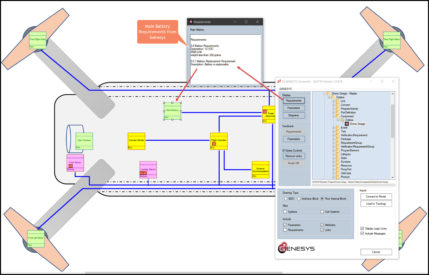

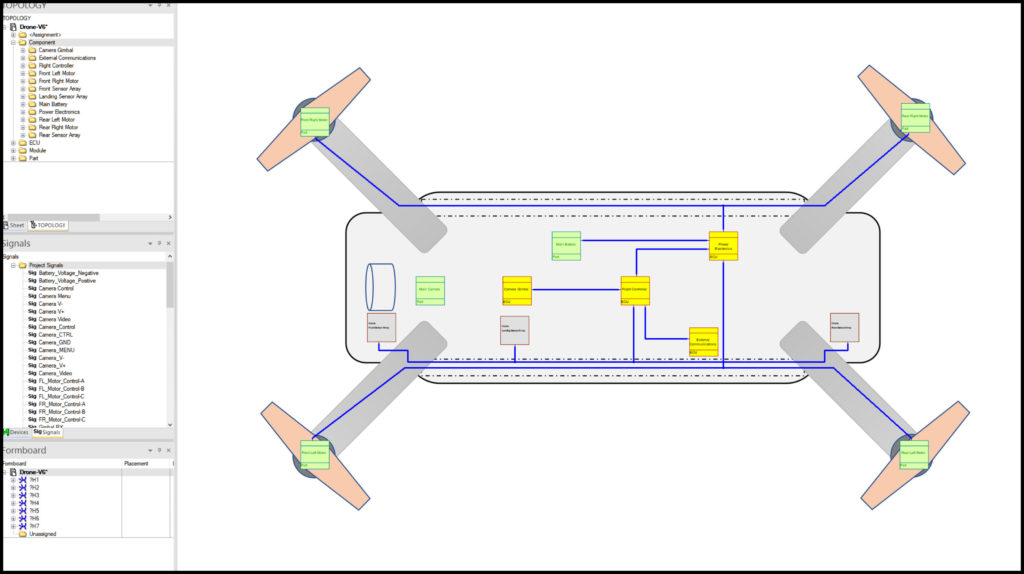

The E3.GENESYS Connector extracts the desired model component or subsystem (e.g., drone) and transfers the ibd to E3.series for wire harness design. Utilizing the extended E/E schema in GENESYS, electrical information can be directly assigned in GENESYS and transferred to E3.series.

Direct connection. E3.series becomes connected to GENESYS and the model.

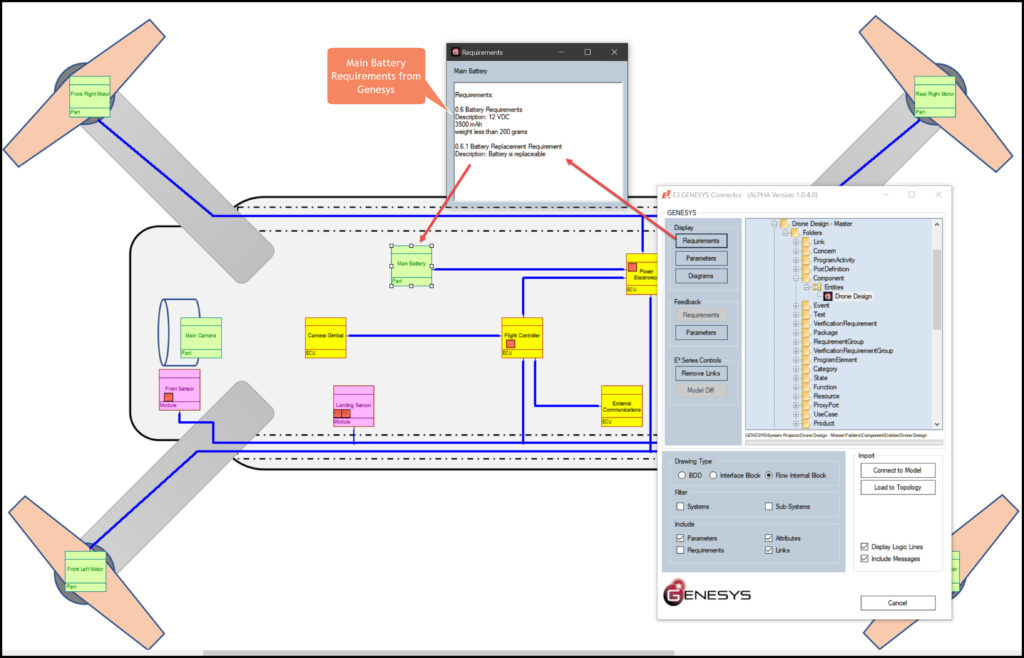

E/E schema extension. GENESYS has new attributes and types that enhance the model transfer to E3.series.

Component selection. The user can navigate the model to the specific component of interest for transfer to E3.series.

Model viewing. The detailed design team can view requirements, diagrams, and parameters directly from E3.series.

The model provides a relationship approach to product definition that is not possible with documents. The more robust the product definition, the fewer design errors.

The model must be connected and utilized by the implementation and test teams. Model relevancy throughout the product life cycle is key to success.

As products become more complex, the risk of design intent and implementation divergence becomes more real. Verification events provide consistency checks throughout the product life cycle.

During the product model creation, an extended schema was used to provide specific attributes for E/E design. The attributes enable connector selection and pin assignments. The schema extensions are necessary for connecting the model to detailed design.

The E3.GENESYS Connector opens the GENESYS project for review and design envelope extraction based on component or subsystem. The drone electrical subsystem is transferred to E3.Series Topology editor.

The E3.GENESYS Connector bridges the GENESYS MBSE tool with E3.series Topology Editor. The connector opens a window into GENESYS through a dialogue box. The user can view and select from the project list. Once the project is selected, requirements, diagrams, and parameters are all viewable.

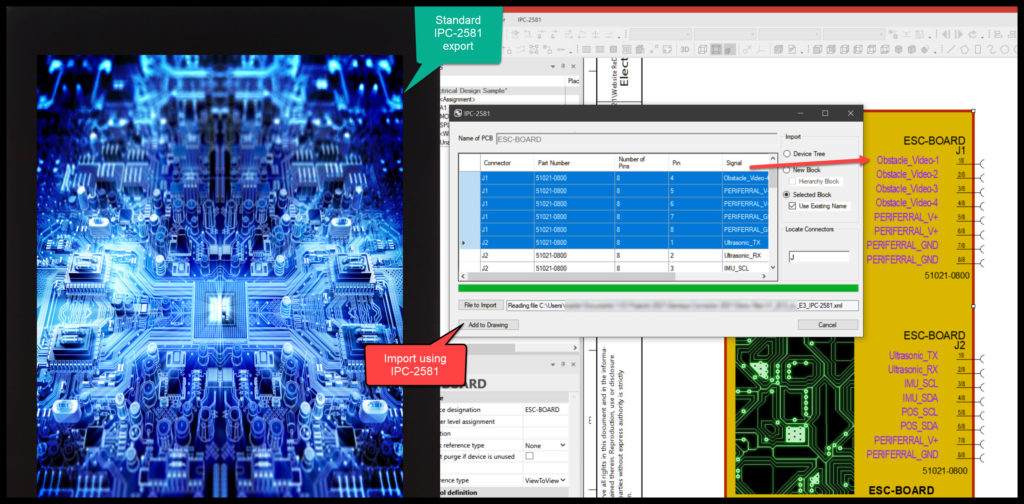

In many cases, the PCB is designed prior to the harness design. The design envelope imported from GENESYS can be augmented by PCB information through an IPC-2581 importer. E3.series combines the PCB connector information from multiple boards using IPC-2581 with the GENESYS model.

The E3.GENESYS Connector fully supports the Digital Engineering process. Documents are exchanged for a model-based design process.

The E3.GENESYS Connector is an E3.series add-on. No need to learn another tool and time to productivity is accelerated.

The E3.GENESYS Connector opens a connection from E3.series to GENESYS. The E3.series user has full access to the GENESYS model in terms of project selection, diagrams, requirements, and parameters.

The E3.GENESYS Connector eliminates the need for the model to be translated into documents for the design team. This time-consuming activity breaks the connection to the model.

In many cases, the PCB is designed prior to the harness design. The design envelope imported from GENESYS can be augmented by PCB information through an IPC-2581 import. E3.series can combine the PCB connector information using IPC-2581 with the GENESYS model.

The E/E schema extensions enable specific implementation information to be added to the model and directly transferred to E3.series. The capability can be used for design reuse or in the case of systems engineering picking a specific component.

The Digital Thread is a foundational element of a successful Digital Engineering implementation. Digital conversations involving procurement, design, manufacturing and field service replace email and paper documents. Decisions and rationale are captured and provide traceability.

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.