Panel Builder 2026: Faster, smarter, and more traceable builds

Panel shops face increasing pressure to deliver faster, smarter, and more cost-effective builds. Panel Builder 2026 for E3.series, expands Zuken’s digital platform for wiring and assembly work instructions. Engineers, production managers, and technicians gain consistent, processed, shorter build times, and stronger traceability.

The problem: disconnected instructions slow production

Many shops still rely on paper packets, tribal knowledge, and late-stage rework. That leads to missed steps, wiring mistakes, and schedule risk. When task lists, views, and machine programs don’t line up, technicians lose time and managers lose visibility. Panel Builder 2026 closes those gaps with structured tasks, clear visuals, and connected outputs.

If you design switchgear, build industrial cabinets, or manage electrical enclosure production, here are eight new features you need to know.

- Multiple Build Tracking

- Skip Attribute

- Expanded Task Filtering

- Import New Tasks when Reloading

- PWA 6000 Output

- 2D-3D View Toggling

- Pin-level Wire Sorting

- Completed/Total Indicators

Wiring task management that scales

Engineers who model panels with Panel Builder don’t just design the enclosure; they also define how the cabinet is built. By defining the exact order of operations, manufacturing directors can optimize and reduce time to build.

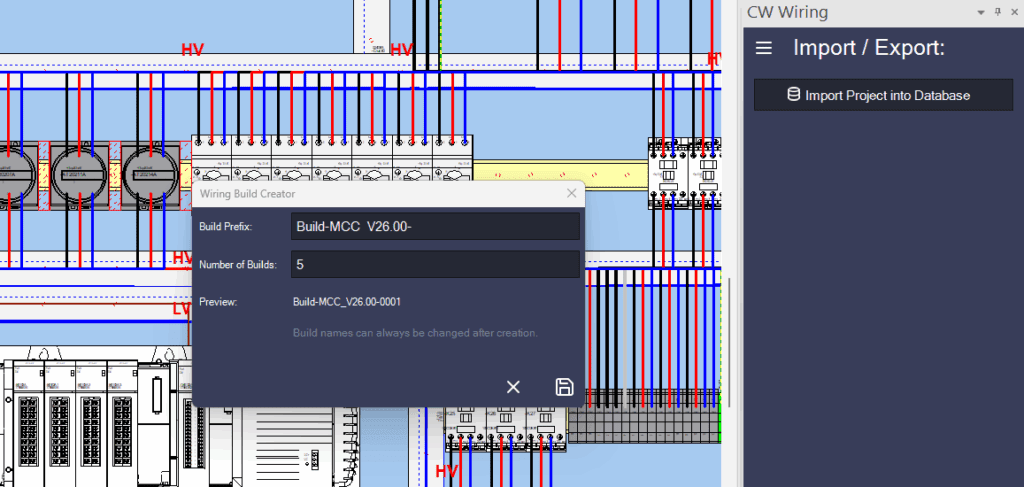

Panel shops often produce multiple builds of the same design to support high-volume orders and reuse proven configurations, thereby optimizing their efficiency and productivity. Multiple Build Tracking enables production supervisors to drive wiring tasks for identical panels while tracking a complete history linked to a single project. When a panel design is imported into the manufacturing database, a new dialog appears to direct technicians on how many builds of the design to make.

Panel Builder 2026 includes additional enhancements to streamline build preparation and work assignments for engineers and project managers:

- The new Skip Attribute feature allows you to exclude or include devices or pins based on attribute values. For variant builds, this is critical to eliminate installing extraneous wires that connect to nowhere.

- The Assembly Task Manager’s expanded task filtering supports location, assignment, category, and subcategory. Engineers tag components so that technicians can filter and group work items, thereby maximizing efficiency.

- Assembly Task Manager now only imports new tasks when reloading the design file. This enables late-stage design changes without disrupting technician workflows.

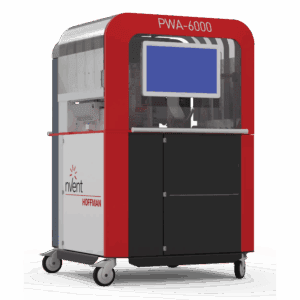

Connected manufacturing automation

Panel Builder 2026 strengthens Zuken’s connected manufacturing strategy with expanded support for automated wire processing. Enhancements to the PWA 6000 output ensure alignment with Wiring Task Manager wire data and sort order, enabling manufacturers to maintain accuracy and efficiency throughout the entire engineering and assembly process.

Assisted technician guidance—clearer, richer, faster

Panel Builder 2026 continues to simplify the use of digital work instructions while providing more information than ever.

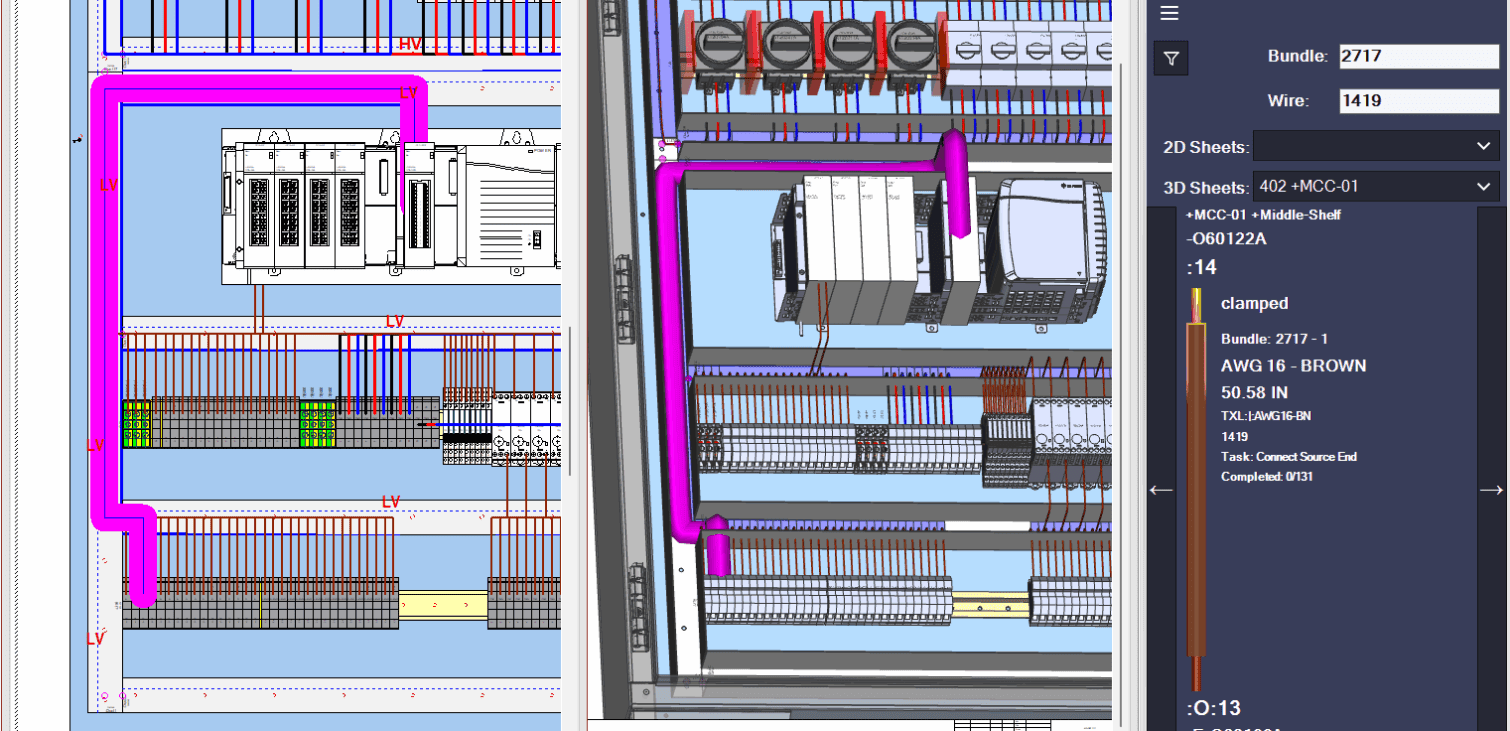

Digital work packages often feature multiple 2D and 3D views to provide technicians with various angles for clear visualization and understanding. With 2D-3D view toggling, technicians can select views from a drop-down menu that indicate the location of the in-work wire or device, making it easy to find the perfect visualization for each task.

Additional enhancements to help guide technicians with visual clarity:

- Engineers can optimize work instructions with pin-level wire sorting, offering more granular control than traditional device-level sorting.

- The completed/total indicators on the Assembly Task Manager clearly indicate how many tasks remain.

Benefits you can measure

- Shorter builds: Optimized task order and on‑machine programs reduce hands-on time.

- Higher first-pass quality: Clear visuals and pin‑level sorting minimize errors.

- Better traceability: Multiple Build Tracking and progress indicators create a clean audit trail.

- Change resilience: Selective task re-import absorbs late changes without chaos.

Conclusion: Ready for connected, technician-friendly manufacturing

Panel Builder 2026 propels teams towards connected, automated, and technician-friendly manufacturing. The new release streamlines task management for engineers and production managers, providing technicians with intuitive digital work instructions. These enhancements reduce build times, improve quality, and strengthen traceability.

Next Steps

- Download: Get Panel Builder 2026 to start using the new features, beginning December 15, 2025.

- Watch: On-demand webinar—What’s New in Panel Builder

- Explore: Visit the E3.series Panel Builder and E3.panel product page.

- Talk to us: Want to digitally drive manufacturing automation equipment? Contact your account team to enable the new output.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog