In engineering, we would rather prevent problems than solve them. That’s the quiet power of Engineering Data Management (EDM). EDM acts as a silent partner in your workflow, anticipating chaos and replacing it with clarity. This proactive approach is the foundation of effective risk management. This post explores how EDM brings proactive precision to manage risk in your engineering environment. But first, picture this:

Keys, Meet Ball Pit. Ball Pit, Meet Keys

You’re in a ball pit with your nephew, living your best adult-child hybrid life, when clink, your keys vanish into the abyss. You know exactly where they are: somewhere between the red ball that smells like feet and the blue one that’s suspiciously warm. But you’re exhausted, so you send your tiny sidekick in after them like a pint-sized Indiana Jones.

You give him directions: “Take three steps forward, veer left at the green ball, then dig like a caffeinated squirrel.” But just as he dives in, another parent yells, “No, Timmy, my keys are under the yellow ball!” Now it’s a full-blown toddler traffic jam. Kids are cannonballing in, balls are flying, and your nephew is now building a fort instead of retrieving your keys.

At this point, you either keep shouting over the chaos or sigh dramatically and bellyflop back in yourself. And as you emerge, sweaty and slightly defeated, you spot the electronic lockers you ignored earlier. You know, the ones that cost a dollar and would’ve saved you from this plastic-ball nightmare.

Why didn’t you use one? Maybe you thought, “This won’t happen to me,” or “I’m not paying a whole dollar to store my stuff!” You did the mental math and decided the risk of losing your keys was lower than the cost of convenience. Spoiler alert: it wasn’t.

Ball Pit Without Lockers

Now, imagine this whole mess is your engineering team. The keys? That’s your design data. The ball pit? That’s the chaotic file server where data goes to disappear. And Timmy? He’s the new engineer trying to find the latest schematic version by digging through folders named “FINAL_v2_REAL_FINAL_THISONE.”

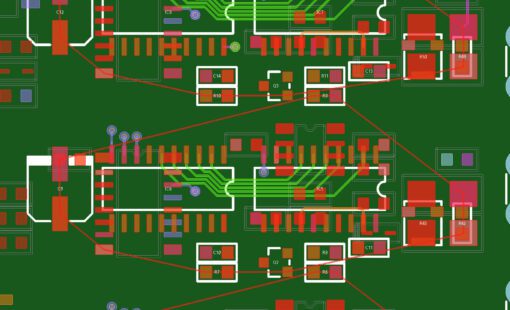

Many companies today operate without EDM and struggle with risk management. They jump headfirst into the ball pit with keys in their pockets. Outdated practices include using uncontrolled file servers, under-managed cloud storage, or disconnected tools. Version control is done, not by a data management system, but by renaming files and manual change tracking.

This approach leads to many problems. Engineers within the team don’t know where to find or which version is the latest. Without knowing where versions reside, it’s impossible to understand changes across versions, leading to engineers wasting time perusing entire datasets instead of just what’s new. Without robust data management, your team relies on tribal knowledge, a risky practice in the current work culture of frequent personnel change.

Ball Pit Surrounded by Lockers – Zuken’s EDM Solutions

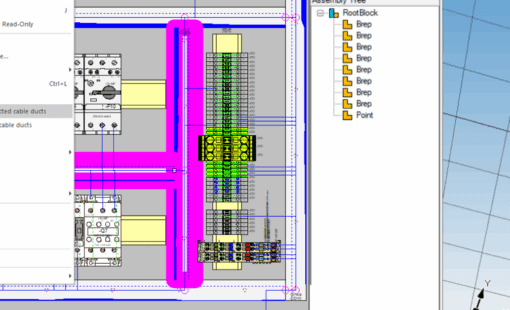

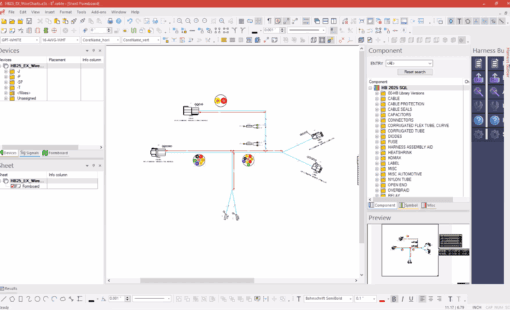

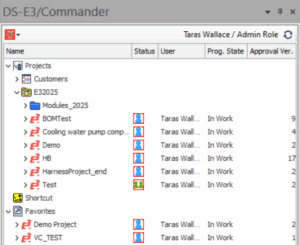

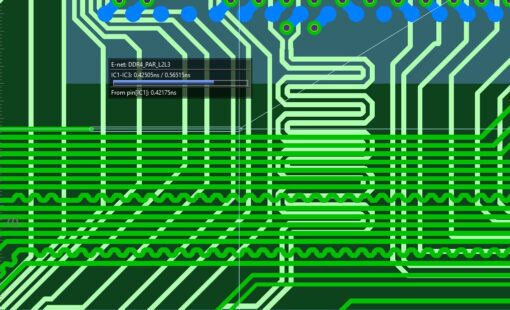

Engineering Data Management is more than a locker for your data. It maintains and secures your intellectual property integrity through change tracking, version control, and access management. It provides easier collaboration through workflows and searchability to find the data you need when you need it. It is the risk management for engineering data.

DS-E3 and DS-CR are Zuken’s premier EDM solutions and the locker systems you should’ve used from the start. EDM stores your data safely, tracks every change, and ensures Timmy doesn’t have to spelunk through a digital ball pit to find what he needs. It’s got version control and access management, and it even integrates with your workflows, so no more guesswork, no more chaos, and no more “Where are my keys?” moments.

DS-E3 and DS-CR can do so much more as well. If you have a PLM system, we can connect to that too, so that the rest of the team can access the critical data that makes your engineering company run.

So next time you think, “I’ll just wing it,” remember the ball pit. And maybe, just maybe, use DS-E3 and DS-CR.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog