This is part two of a three-part series exploring modular design. This post explores the Configure to Order approach to product line engineering.

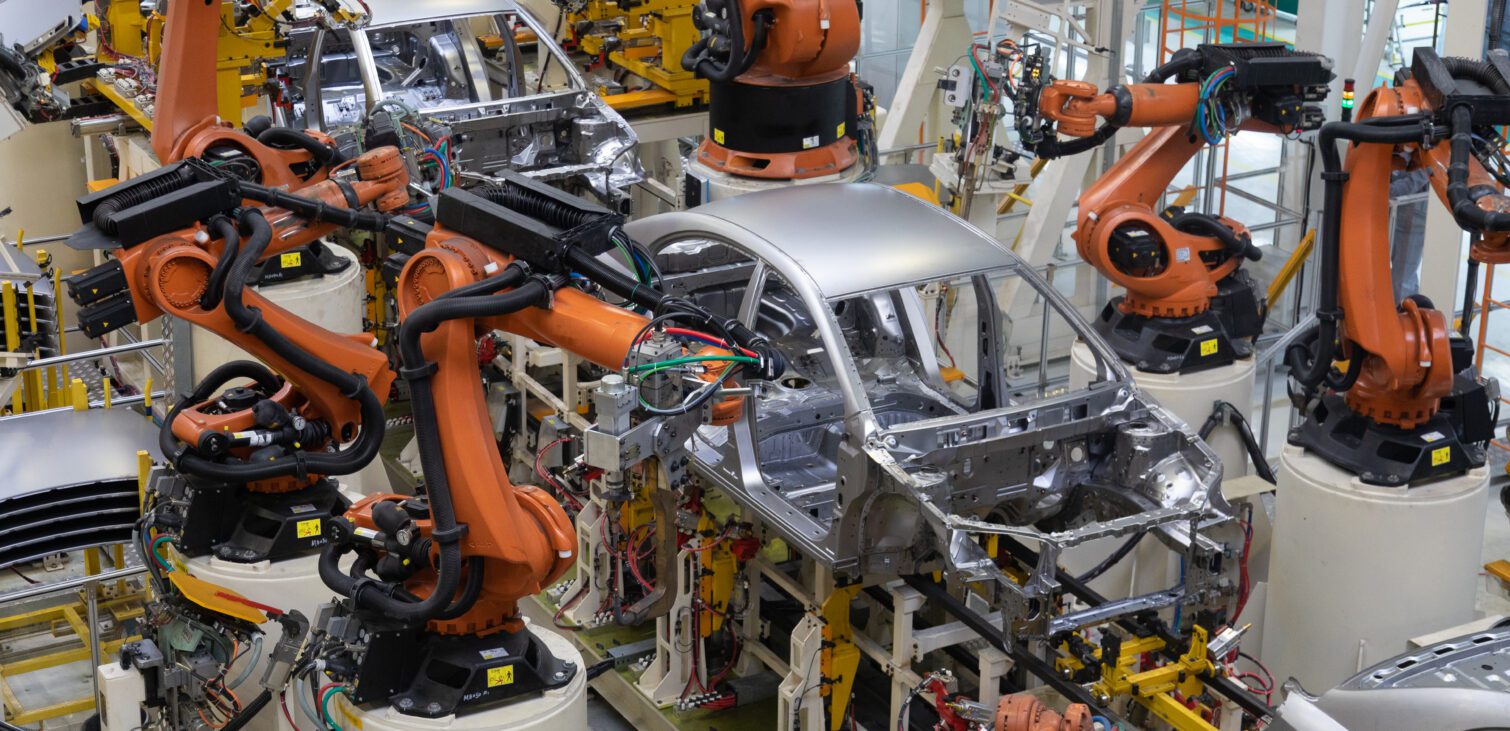

Configure to Order meets the customer’s demand by providing configurable variations. When you buy a car, you choose from white, black, silver, or red, not an infinite color palette. You’re happy because you feel you get a distinct vehicle configured to your liking. But by limiting the configurability choices, the car manufacturer streamlines manufacturing and simplifies logistics, and can pass the savings along to you.

Companies implement Configure to Order to give the customer choice. Products are rarely one-size-fits-all. Sometimes, it’s a preference. I like picking the color of my phone. Sometimes, it’s a requirement; a rail company must support 120V outlets by the seats on American trains and 240V for European trains. Whether for choice or need, nearly every company creates a product line, a group of related, configurable products.

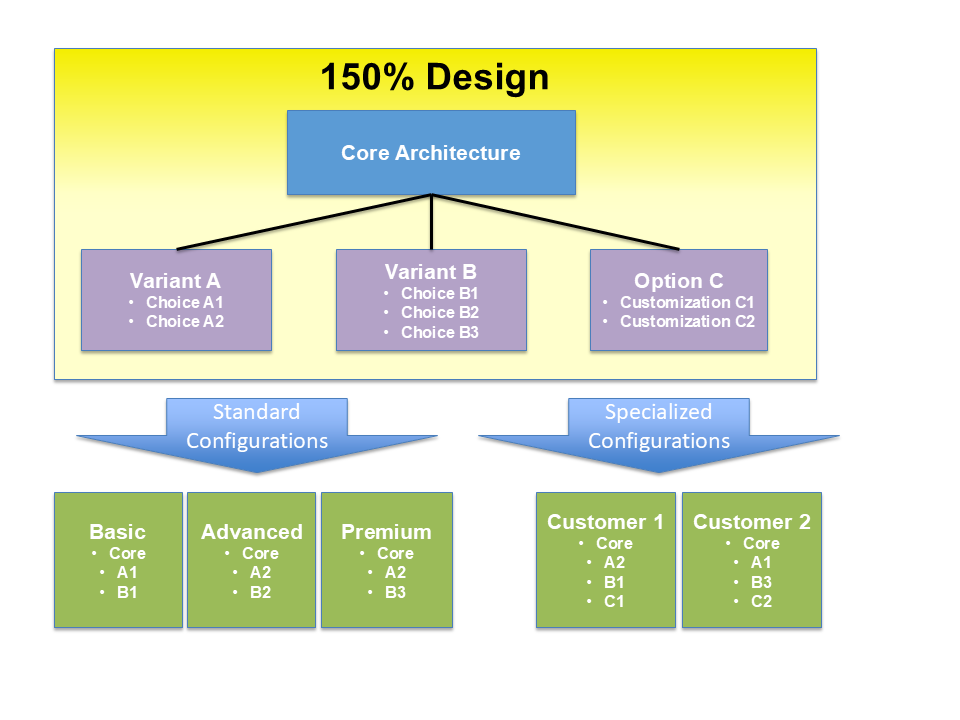

Behind the product line catalog lies a great deal of engineering and planning. A product line engineer plans the various configurations and captures them in a 150% design. This comprehensive model contains all possible variations in a single framework. When the customer selects their configuration, production toggles features from the over-engineered 150% design to generate the exact build. This approach enables agile customization and reduces production complexity.

Product Line Engineering

The product line methodology starts with a product backbone that accommodates all variations. For example, an airplane’s core product backbone might include the fuselage, wings, engines, and basic system functions. Since the core architecture does not change, manufacturing can begin production before finalizing the customer’s configuration.

Some available features would be variants with predefined choices. For example, with an airplane, the airline could choose from several certified avionics packages. With variants, the engineer can predefine all the interfaces between the variant and the core architecture. By limiting choices within a variant category, logistics can stock the parts for those configurations with the confidence they’ll be used eventually, reducing lead time. The challenge is to minimize the number of variants and choices while offering enough breadth to satisfy wide consumer preferences.

Unfortunately, even Configure to Order products may have one-off customizations. For example, a major airline may require its airplanes to carry the new state-of-the-art HD touchscreen infotainment system. The product line engineer could not anticipate integrating a technology that hadn’t existed. In a case like this, the engineering team would work to integrate this new subsystem, then save the work as an option for future builds. Fortunately, the team’s hard work gets reused when another airline requests the same touchscreen. A product line engineer may not be able to anticipate all variations, so the product line must support product maturation and evolution.

Understanding 150% Design

Before the age of complex CAD (computer-aided design) systems, product line engineering involved considerable copy and paste actions. If a military agency asked a defense contractor for 20 fighter jets with specific capabilities, the product line lead would start by identifying the most similar existing configuration. The engineering team would copy that design and make changes from there. They’d leverage reuse as much as possible. However, this method relied on the product engineer’s experience and was only as efficient as that engineer’s ability to pick the most similar design.

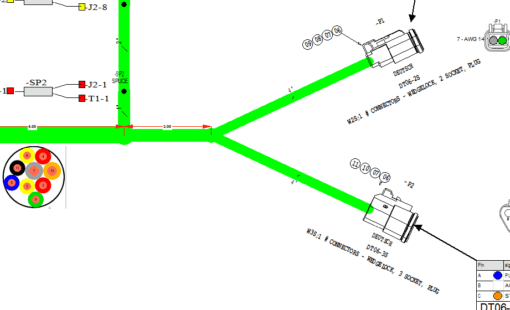

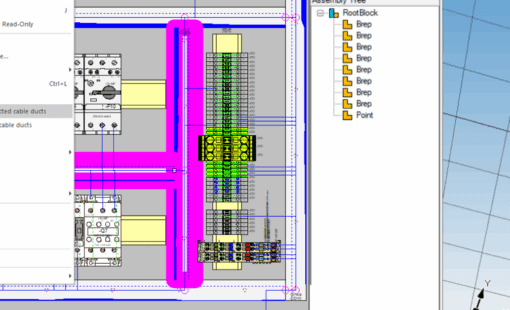

A 150% design saves all variants and options into a single design. Engineers no longer design electrical schematics and mechanical models order-by-order using copy and paste. Instead, all variations are stored in a single schematic, a single mechanical model. This is only possible as computing power and CAD software have grown to handle large, complex data models.

A 150% design requires significantly more upfront planning but has considerably greater downstream benefits. When starting a product line, it may be tempting to engineer only what’s needed for the first order. However, that approach fails to leverage the benefits of Configure to Order.

A car company wouldn’t implement the basic sound system and then wait for someone to ask for the Bose sound system before integrating it. No, they’d build the core product architecture to accommodate both standard and advanced sound systems. Mechanical engineers would design the dash and doors to fit either set of radios and speakers. Electrical engineers would ensure electrical connections are compatible with both. That way, one manufacturing line can integrate either system with minimal disruption.

Zuken’s Solution for Configure to Order

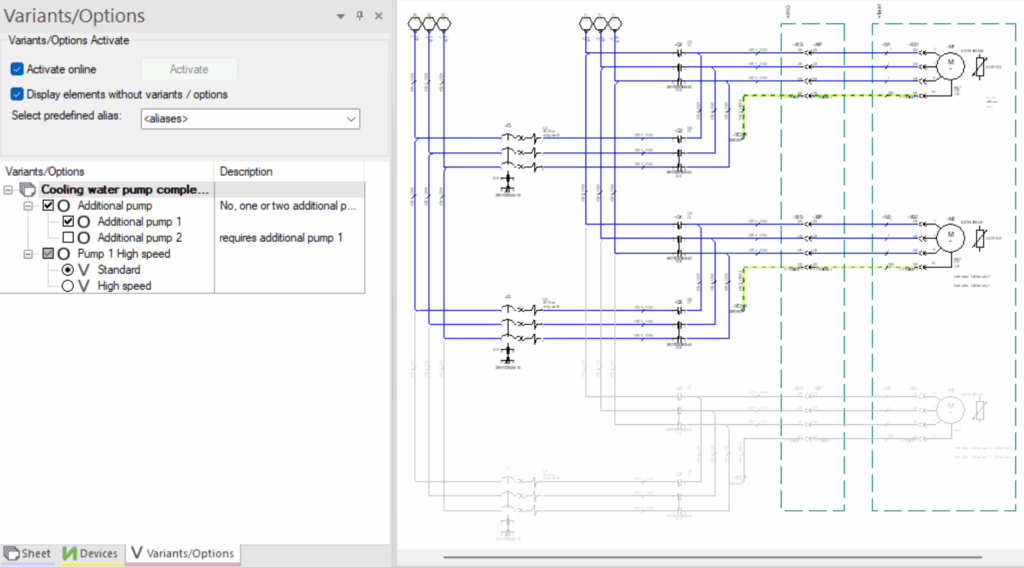

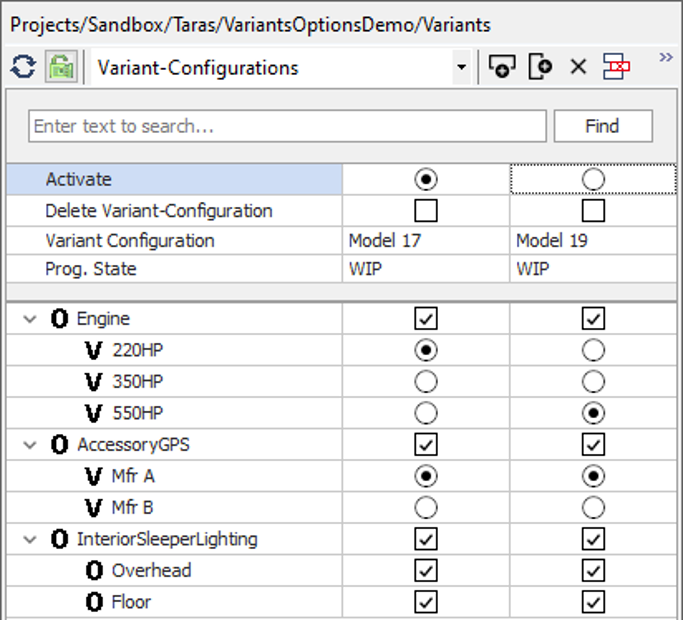

Zuken’s E3.series supports 150% design. Engineers can tag modular blocks, connectors, wires, and even full drawing sheets with variants or options. Variant categories store sub-variants to represent the choices. The sales team and customer simply toggle options on and off from a list of checkboxes to construct their configuration. When production views a

A digital thread is required to track the usage of platforms and modules across projects. A 150% design often requires multiple engineers to work on it simultaneously; Zuken’s DS-E3 manages user controls and project access. It also maintains a work-in-progress project vault, allowing you to track project progress in the design phase, not just when it’s released. DS-E3’s product variant manager tracks the exact configuration for each build, enabling the engineering team to effectively collaborate and clearly visualize the product line’s evolution.

Configure to Order has design challenges but offers immense savings by balancing customization and reuse. A 150% design increases upfront engineering but streamlines the process from sale to manufacturing. Digital engineering is key to product line engineering to manage and trace variations.

Ready to take your Configure to Order processes to the next level? Explore how Zuken’s tools for 150% design can empower your team to engineer with precision, speed, and confidence.

Related Products and Resources

- Blog

- Blog

- Blog