As we step into the new year, it’s a great moment to look back on what made last year meaningful. We’ve gathered the highlights and are excited to share our Top 10 Blog Posts of 2025. Thank you to our incredible contributors, and to you, our readers, for continuing to make this blog a trusted resource year after year.

We hope your New Year kicked off on a high note. More is ahead, and we can’t wait to share what’s coming next in 2026.

10. Modular Design Strategies Explained: Platform-Based vs. 150% Design

By Geoffrey NG

Read up on modular design strategies, and compare platform-based and 150% design so engineering teams can balance customization, reuse, and cost. You will learn when each approach is best suited and how it affects the efficiency and complexity of product development.

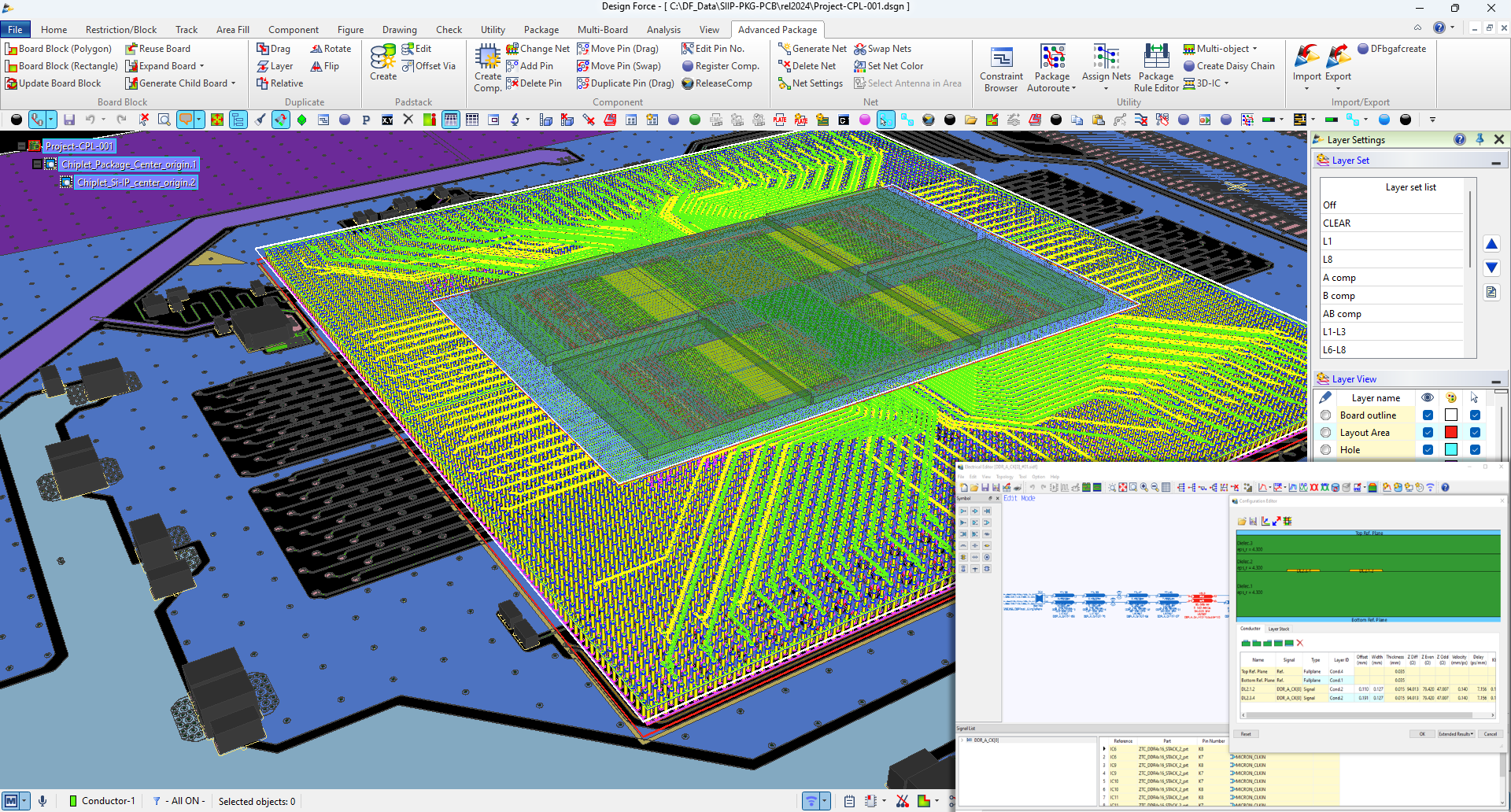

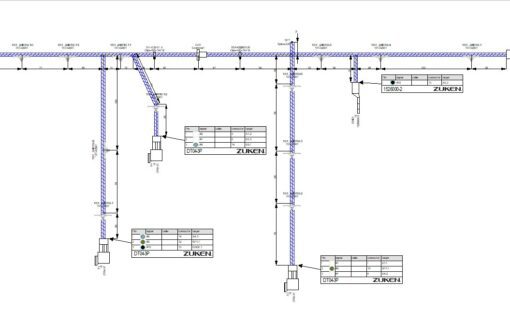

9. Engineering the Future: Zuken’s Role in Panel-Level Packaging Innovation

By Steve Watt

From smartphones to servers, modern devices demand ever-faster communication and smaller footprints. That puts pressure on every layer of semiconductor packaging, and Panel-level Packaging is emerging as a critical focus area. The interposers that connect chiplets are now at the center of this transformation.

8. EDM vs PLM: Choosing the Right Data Management for Engineering Teams

By Joe Richlen

In engineering and manufacturing, managing design data isn’t just about storage. It’s about control, collaboration, and continuity. While Product Data Management (PDM) and Product Lifecycle Management (PLM) systems often steal the spotlight, Engineering Data Management (EDM) systems quietly deliver focused benefits that keep engineering teams productive and precise.

7. Engineering Data Management Connects Engineering to Manufacturing

By Chris Robles

Manufacturing and engineering too often work in silos. Engineering data management for manufacturing helps the two teams collaborate with clarity and accuracy, ensuring both sides work from the same data.

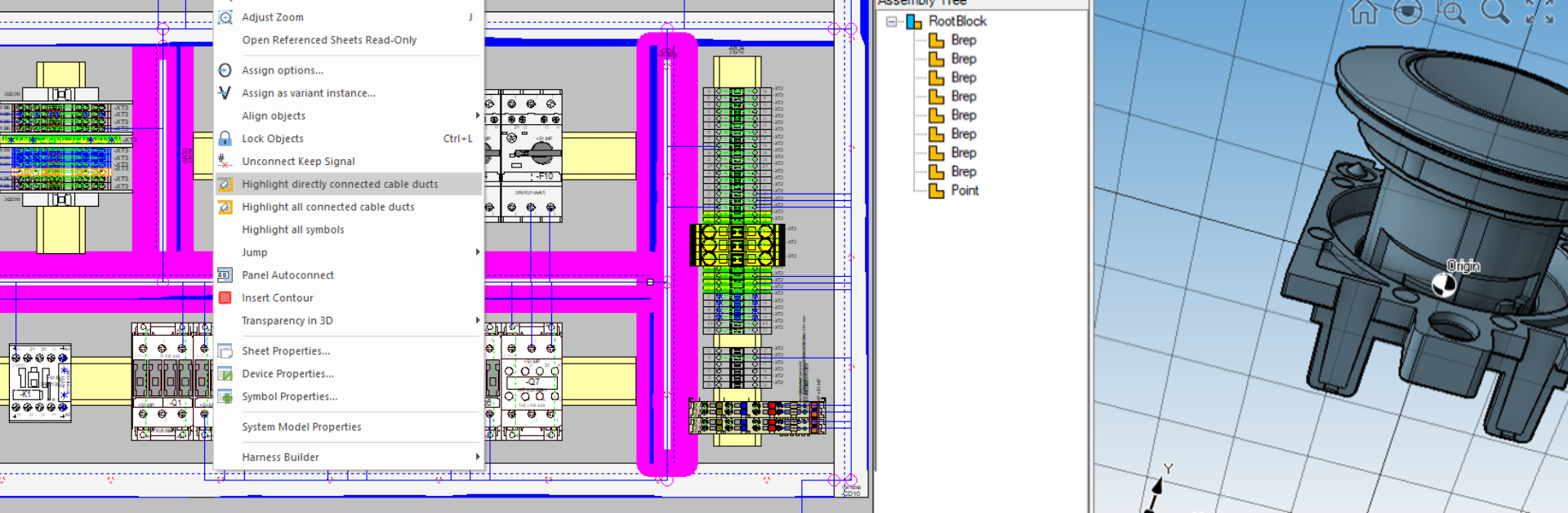

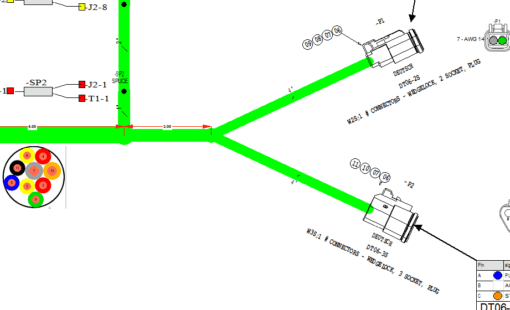

6. What’s New in E3.series 2026 for Electrical Design

By Geoffrey NG

The 2026 release of E3.series introduces over 70 enhancements designed to help you design faster, reuse intelligently, and collaborate clearly. As product complexity continues to rise and timelines tighten, these updates focus on reducing clicks, improving performance, and capturing more data for design reuse.

5. Top E3.series 2026 Features for Smarter MCAD Electrical Integration

By Geoffrey NG

Harness projects move fast. Space is tight, options multiply, and changes never stop. MCAD electrical integration in E3.series 2026 helps electrical and mechanical teams stay in sync without extra clicks or manual cleanup. The 2026 release strengthens data exchange, improves flattening accuracy, and speeds the ECAD–MCAD round‑trip.

4. Harness Builder 2026: New Features to Accelerate Wire Harness Manufacturing

By George Ross

Speed and quality define success in harness manufacturing. Harness Builder 2026 adds features to accelerate quoting, reduce manual entry, and connect your shop to automation. If you design electrical systems, build wire harnesses, or run IT for manufacturing, these updates were built for you.

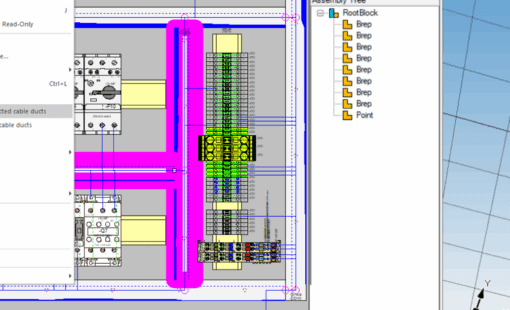

3. What Panel Engineers and Manufacturers Need to Know About E3.panel 2026

By Mike Majewski

Panel engineers face increasing complexity and tighter timelines. They need smarter tools to accelerate design without sacrificing accuracy. E3.panel 2026 delivers smarter automation, streamlined workflows, and enhanced 3D handling to help panel engineers design faster and document with confidence.

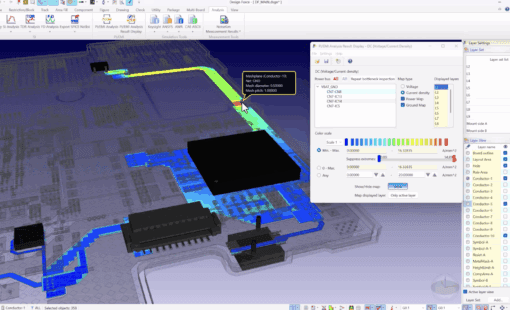

2. What is a Digital Twin in Manufacturing?

By Bob Potock

Manufacturing is evolving rapidly, driven by digital engineering innovations transforming how engineers design, test, and produce products. Among these innovations, digital twins have emerged as a pivotal technology, especially relevant for electrical and PCB engineers striving for efficiency, accuracy, and reliability.

1. Managing Complexity with the STRATA Methodology

By Andy Henderson

In complex systems engineering, teams often struggle to connect requirements, behaviors, components, and verification into a coherent model. The STRATA methodology helps manage that complexity by structuring system design in logical layers—keeping teams aligned, models consistent, and decisions traceable.

Related Products and Resources

- Blog

- Blog

- Products

- Blog