This E3.series customer success story highlights how collaboration between Zuken, PAMI, and Dyna Industrial led to the faster delivery of remote-controlled mining equipment—captured on location in snowy Saskatchewan.

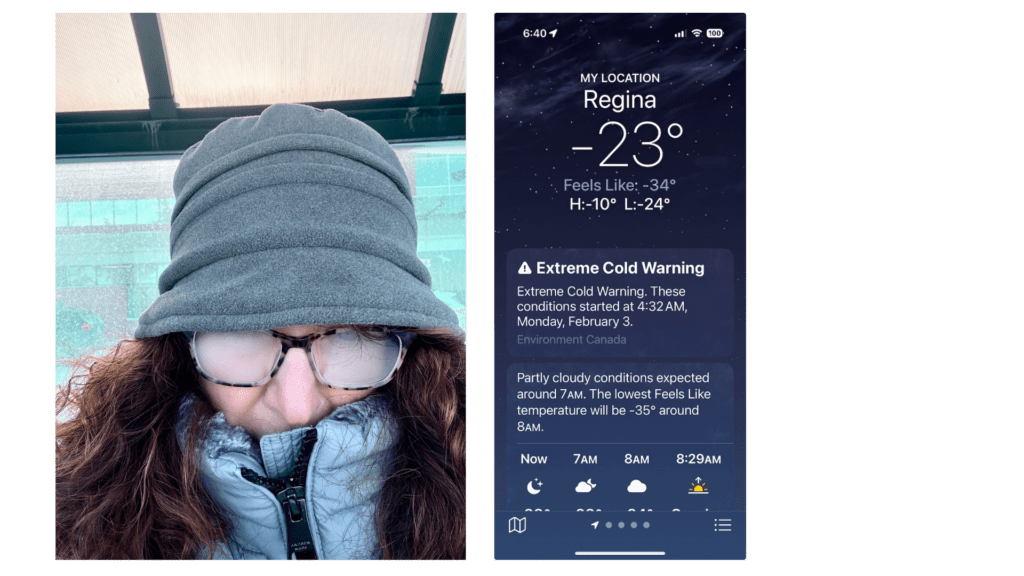

When your boss tells you you’re going to Saskatchewan in February…

…you have two thoughts: 1) Do I even own boots that warm? and 2) Where exactly is that?

So off I went—passport in hand, carry-on stuffed with layers, and wearing the puffiest coat I own—to capture a story that had been unfolding behind the scenes: a collaboration between PAMI, Dyna Industrial, and Zuken that brought next-generation mining equipment to market faster than anyone expected.

The Mission: Capturing a Real E3.series Customer Success Story

Our goal was simple: film a customer success story that shows how PAMI, a long-time Zuken customer, used E3.series to help Dyna Industrial modernize their Dyna Bolter. The bolter is a critical piece of mining equipment used to stabilize underground potash mines.

Spoiler alert: the final machine included remote control capabilities, which was a first for Dyna. Bringing that feature to market meant tackling complex electrical system design, fast turnarounds, and high customer expectations. That’s where PAMI and Zuken came in.

Meet the Team Behind the Story

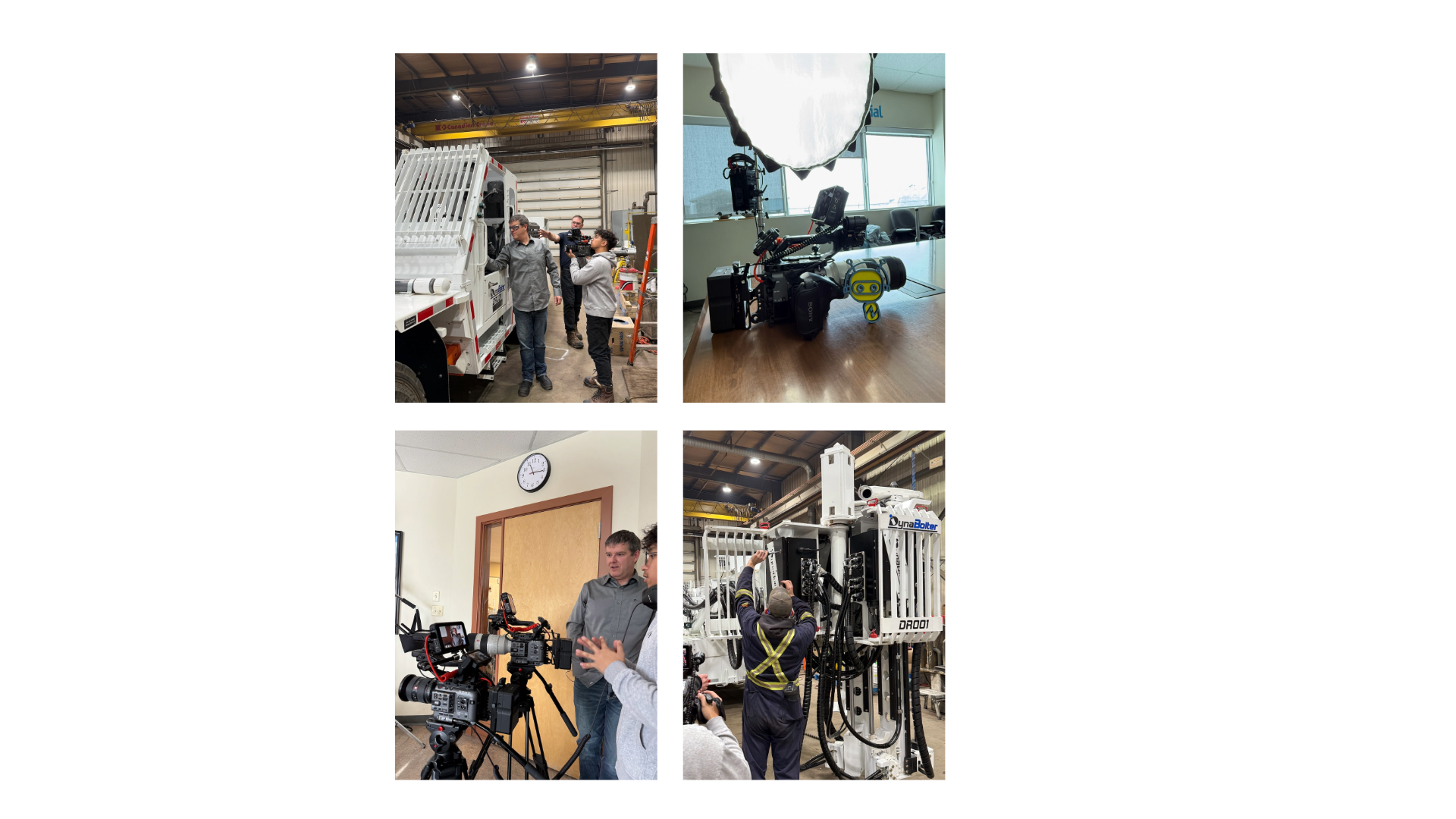

We met up with Kevin Anderson, Dyna’s no-nonsense project manager, who somehow manages to make heavy mining equipment feel approachable. We were joined by Bryan Lung, director of operations at PAMI, whose quiet confidence makes it clear he’s seen it all in harness design. And then there’s Candice Bauer, who made all the introductions and was essentially the glue for this project.

Together, this team made it all look easy. They integrated new features—delivering them smoothly, efficiently, and with zero drama. Kevin summed it up perfectly: “If I’m not thinking about it, that means it’s working.”

Behind the Scenes at Dyna Industrial

This was my first time filming at a working industrial facility, so naturally, I was a little unsure what to expect. We donned our borrowed steel-toed boots, and we put on those oh-so-attractive safety goggles. Once suited up, we got to work. We toured the shop floor, staged our shots, adjusted for lighting, and tried not to trip over cables. Somewhere in there, we captured some great sound bites, a few candid photos, and one shy technician who clearly did not want to become famous.

What We Learned from This E3.series Customer Success Story

More than anything, this trip reminded me that great solutions aren’t just about software. The real power comes from people working together—with trust, shared goals, and the right tools.

Dyna brought the challenge. PAMI brought the expertise. Zuken brought E3.series.

E3.series played the starring role. Its ability to handle complex harness designs and integrate with downstream manufacturing tools helped the team move faster—without sacrificing accuracy. That meant fewer delays, better documentation, and a smoother path to delivery.

Not All Work

Yes, Bob and I ventured out into the cold. A short walk to lunch was enough to confirm that yes, -23º is a number that shouldn’t exist—and yes, the rabbits in Canada really are that big.

The good news? The hospitality was even warmer than the snow was deep. And yes, we took a few photos that might just make it into internal presentations…but probably not the next product brochure.

Why This Story Matters

This E3.series customer success story is about more than just a roof bolter. It’s about what happens when the right people, the right software, and the right partnerships come together.

At Zuken, we’re not just providing tools—we’re part of real-world solutions that help our customers innovate, compete, and grow.

Huge thanks to PAMI and Dyna Industrial for opening their doors and letting us be part of their story. The final video and downloadable case study are now live on zuken.com.

Want to Be Next?

Got a story worth sharing? Reach out—we’re always looking to feature new examples of collaboration and customer success that showcase what Zuken makes possible.

And I promise, we’ll bring the camera, the questions, and next time…warmer boots.

Related Products and Resources

- Success Stories

- Success Stories

- Success Stories

Ontec uses CR-8000 to develop a next-generation product in less time despite rigorous design constraints