This is the last of a three-part series exploring modular design strategies. See my previous posts for a deeper understanding of platform-based design and 150% design.

Modern products are rarely one-size-fits-all. Customers expect tailored solutions. Whether your company offers a product line with slight variations or delivers fully customized builds, managing design complexity is essential

Modular design strategies provide a scalable solution. Companies develop a core design and extend it with interchangeable modules. As technology evolves or customer trends shift, product lines integrate new modules without starting from scratch. This achieves broad market coverage, efficient manufacturing, and customer satisfaction.

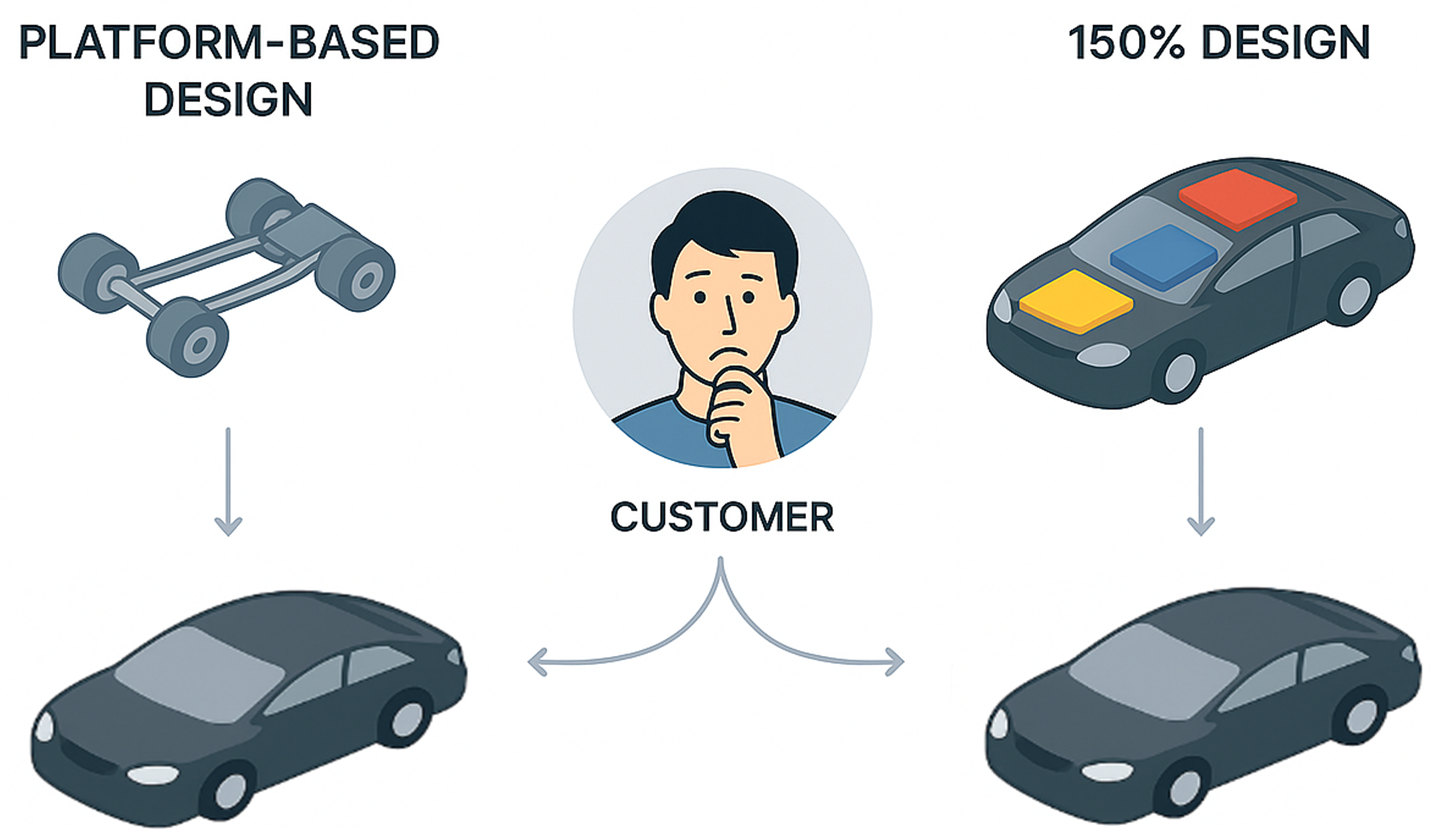

Defining the Two Methodologies

Two proven modular design strategies dominate engineering today. First, we’ll define the two approaches. Then, we’ll explore how to choose the right one for your business.

Platform-Based Design begins with a consistent core product platform. Engineers define standard interfaces on the under-engineered platform where modular subsystems can connect. Once customers specify desired functionality, engineers develop or adapt suitable components and integrate them to create the end product. This approach powers Engineer-to-Order, blending reuse with tailored innovation to deliver unique solutions.

150% Design starts with an over-engineered master model that includes all possible options and variations. Engineers tag each component or subsystem with variant identifiers in the master model. Customers choose their configuration from the predefined list. Engineers then activate only the selected features to create the final configuration. This approach enables Configure-to-Order, helping companies offer differentiated products while streamlining engineering and production.

Both modular design methodologies require trade-offs. Ask yourself these three questions to decide which approach best fits your business.

Who Defines the Variations?

The most important question comes down to business philosophy: who decides what you build? In Platform-Based Design, the customer specifies customizations. In 150% Design, the business sets limits.

This difference highlights how modular design strategies impact the balance between customer choice and business-defined efficiency.

Platform-Based Design fits when customers bring clear, unique requirements. For instance, the military defines new capabilities with each fleet order. A defense contractor using Engineer-to-Order integrates necessary modules into the existing platform to achieve the defined objectives. This approach shines when buyers know what they want and can explain it clearly.

150% Design fits when the business defines the options. That’s why Configure-to-Order is common for car dealers. Shoppers can’t design a car from scratch, but they can pick features from a list. To succeed, the business must understand its customer base and offer the right features.

How Many Variations Are in Each Product Line?

Platform-Based Design accommodates high product variation and long product lifecycles. Take the Boeing 737: while each airline orders custom cabin layouts, avionics, and engine options, the core platform has endured for decades. This Engineer-to-Order model allows Boeing to reuse major subsystems while tailoring modules for every customer, making one-off builds sustainable across a long-lived product line.

150% Design fits when variation is moderate and the product line refreshes frequently. The Ford F-150, for example, introduces a new master design each year to incorporate new technology. Each model year offers a curated list of predefined options, making Configure-to-Order the ideal approach. This balances customer choice with efficient manufacturing and supply chains.

How Long is the Customer Willing to Wait for Delivery?

Customer delivery expectations shape your modular design strategy. Laptop buyers expect delivery within days. A semiconductor factory can wait a few months for new equipment.

150% Design enables faster delivery by limiting choice and simplifying logistics. In Configure-to-Order industries like automotive and consumer electronics, companies often build popular configurations ahead of demand. For less popular configurations, subsystem modules sit ready at the plant and await quick integration. This allows for quick turnaround from order to assembly to delivery.

Platform-Based Design exchanges faster delivery for customization. In Engineer-to-Order industries like defense and industrial automation, engineering cannot begin until the customer defines requirements. While preconfigured platforms help, manufacturing must wait for engineering to finalize the design. Tailored solutions require longer lead times.

Design Software that Meets Your Modular Design Needs

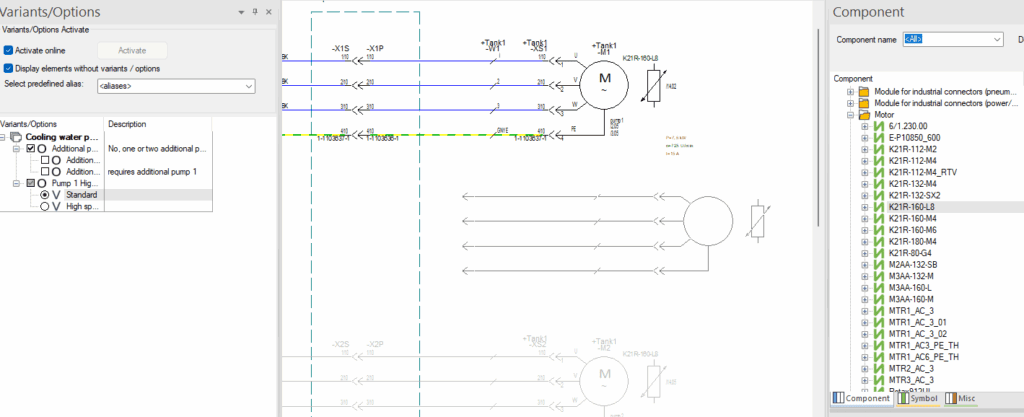

150% Design requires significant upfront effort. Engineers must create a 150% master model, each element carefully tagged. Because production relies on the model, errors are unacceptable once manufacturing begins.

Platform-Based Design requires faster workflows and tighter data management. Engineers are on the clock with every new order. They rely on a database of past builds and approved modules to accelerate design. Accurate file storage and tracking keep every project moving forward.

Fortunately, Zuken has solutions to support both modular design strategies. Our design software supports variants and library-driven workflows, while our DS suite manages design data, modules, and configurations. Once you adopt Platform-Based or 150% Design, Zuken provides tools to streamline engineering and execute your modular design strategy.

>>> Want the full picture on modular design? Catch up with Part 1 and Part 2 of this series.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog