Get constraint management just right and you can save a lot of time and money.

In the first installment on my blog series looking at constraints last week, I explained the importance of understanding your constraint management tool and relevant constraints. This week I will outline how to apply these most effectively without your organization.

Most Effective Way of Applying Constraints

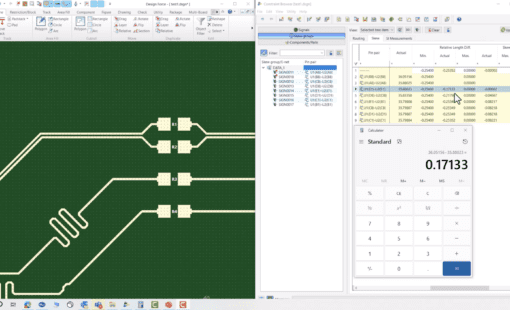

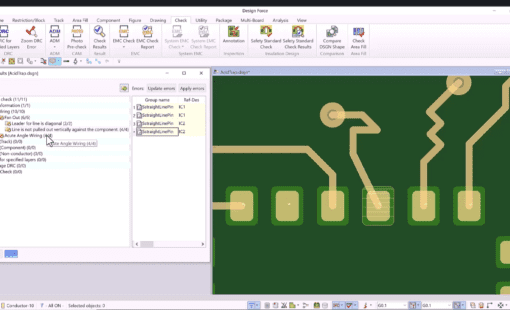

In most cases, constraints are usually controlled by Electrical Engineers, and they drive the rules and requirements for critical nets from their schematic capture package. This is usually the most effective way of managing constraints, as it allows an organization to assign a point of control for maintaining the integrity and intention of a design concept. The down side of this approach is that if any design changes occur, or if critical nets do not meet routing requirements, there can be a significant increase in the potential for board defects. But there is another way – having the flexibility to utilize a Constraint Management tool to pass constraints at ANY point within the design phase, and to report and track changes made. If you do have this capability in your tool, like CR-5000 and CADSTAR do, it is beneficial to take advantage of this functionality to reduce iterations of designs and maintain design integrity.

Don’t Forget to Archive

Once you have figured out where in your design flow you want to apply Constraint Management, it is important to correctly archive the information to ensure that it can be re-used in future designs.

Topology Drawing

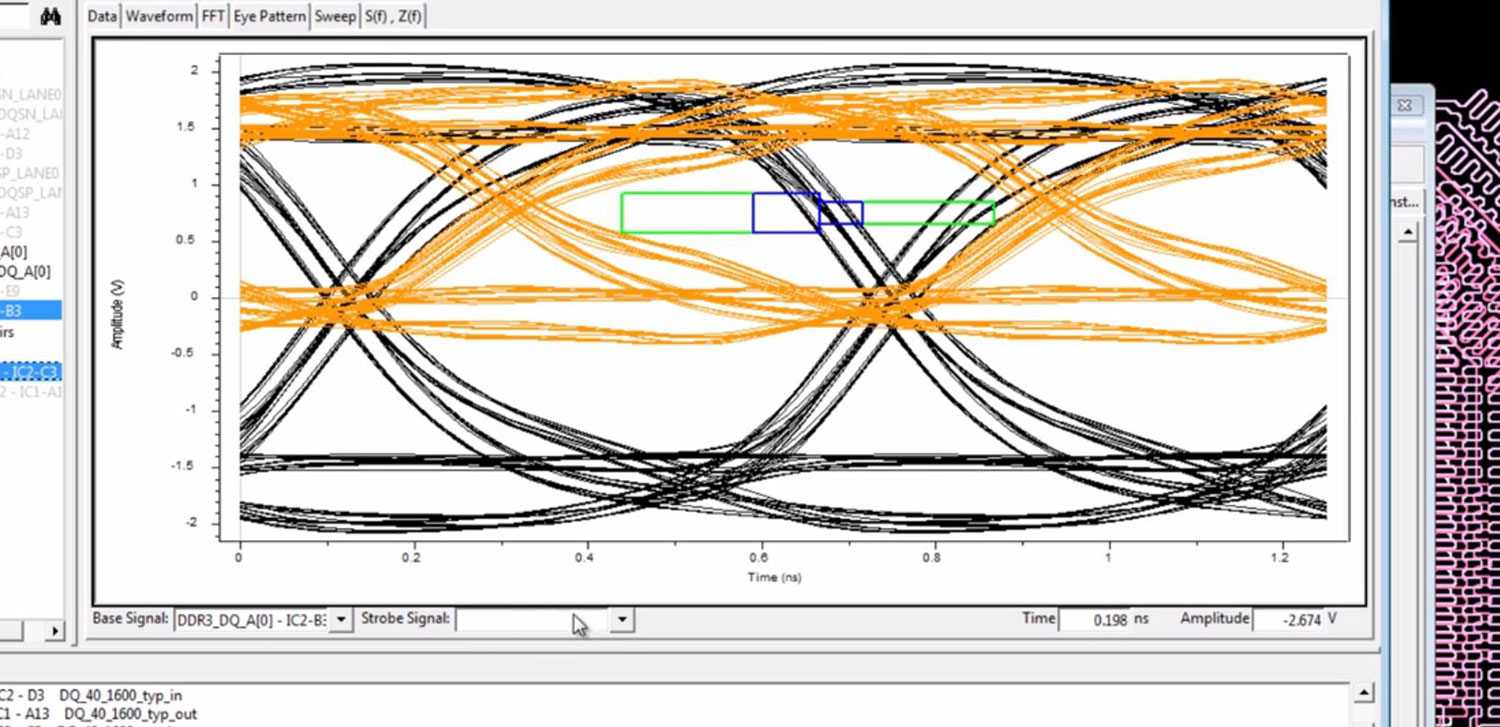

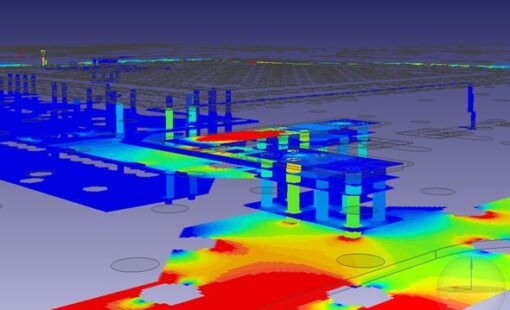

Make sure that the tool of your choice gives you the capabilities to draw topologies, set up stimuli, and create unique board stack-ups for single or coupled tracks for the purpose of carrying out analysis. CR-5000 is great at doing this for example.

This will allow you to spend your efforts not just assigning numbers to nets, but performing true management of constraints at a variety of levels. In the long term, by making use of all the data generated, and by building an engineering knowledge base, you develop an appreciation for the type of constraints and the extent of limitations that can applied to critical nets.

The Straight Jacket of Too Many Constraints

It’s easy to get carried away and over assign constraints and rules, but by over-constraining nets, signals become difficult to route. In more extreme cases, this can even drive up the cost of a PCB if additional layers are required to overcome the routing issues.

ANSWER: To avoid these obstacles, time spent in systemizing your constraints and knowledge base will allow all members of a design team to be more efficient when they are at any part of the development cycle.

Conclusion

The benefits experienced when using Constraint Management tools can apply to anyone from small design centers to globally managed companies. In a time where there is a high turnaround in product to market and human resources, the wealth of knowledge acquired can be organized and re-used to help establish a competitive edge for any respective industry. The key issue to always keep in mind is finding the most effective execution strategy for your individual design flow needs.

Related Products and Resources

- Products

Today’s Desktop PCB Design tools require better connectivity to the outside world. eCADSTAR offers a newer level of connectivity that brings users closer to their parts providers than ever before. This allows Engineers to selected parts and drag them directly to their design. Add the additional functionality of high power Signal integrity verification and Power integrity analysis and you have the Ultimate Desktop PCB Engineering solution.

- Products

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.