So you’re facing shorter design cycle times due to rapidly emerging global competition and the pressure to meet quality control standards, among many other things like drastically changing technologies that deal with faster speeds and sophisticated IC packages; introducing complexity to the simplest of design flows.

Today what I’m going to talk to you about is how to create efficiencies within a design flow to overcome the issues I’ve mentioned above, through the use of Constraint Management tools. As a PCB designer you probably already use a constraint management tool in one form or another, but sometimes they are not being used to their full potential.

Understanding the capabilities and nature of the software being used in the Constraint Management tools is a good starting point. And then to distinguish how it can fit in to become an integral part of your design flow.

Productively implementing constraints and rules for your designs can help:

- Reduce design cycle time

- Improve the scalability of current or developing engineering knowledge base and tested technologies

- Ease the pain of applying design re-use for future product designs.

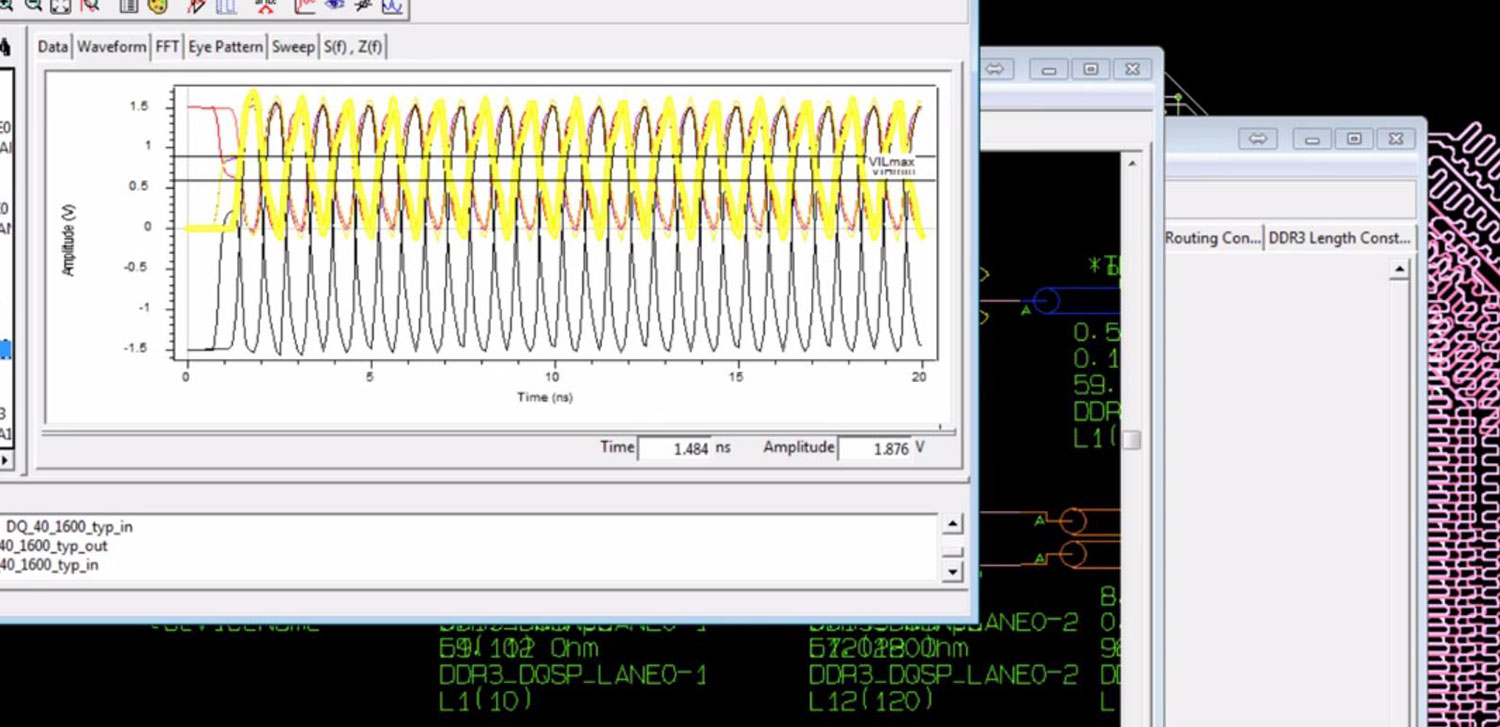

The concept of Constraint Management is very simple. Just set rules and constraints and pass the design to layout! Sure, it can be that straightforward, but as timing requirements become more complex, and you have an array of skew budgets you have to meet based on a data sheet, it becomes evident that not all is as clear-cut as it was originally thought to be. It is important to always start by exploring the capabilities and functionalities available to you. This routine is helpful in defining strategies and standards that will improve your designs and assist you in getting the most out of your tools.

Understanding the Capabilities of Your Constraint Management Tool

Constraint Management tools come in different shapes and sizes.

- Some are meant to handle the basic needs for managing and passing constraints between tool sets.

- Some handle more complex functionalities that not only pass on constraints, but allow you to bridge the gaps between different tool sets in your environment, and be a control unit to determine how your data is being managed.

Whether you are utilizing an existing tool that allows you to assign values to attributes, or if you plan on investing in tools to fit your design flow and enable the implementation of high-speed design strategies, always find out what capabilities are available in order to capitalize on the potential advantages that are being created.

What Constraints are Relevant?

The greatest hurdle in applying constraints is to understand what is relevant to your design, and how the information flows from one part of the design process to the next. As CAD tools like CR-8000 and CADSTAR have evolved, so has the need for applying more unique and stringent requirements.

- It’s now possible to set restrictions or add characterization to signals from any point within the design flow – including schematic entry, PCB layout, and even signal integrity analysis.

- Interfaces to additional simulation and verification software provide designers with the ability to pass on constraints that even extend to other tools outside your CAD system. So it is vital to understand from what direction you want to pass constraints and what information is being passed.

Next week I will look at the most effective ways of applying constraints to take into account your organization structure and to avoid over constraining.

Related Products and Resources

- Products

Today’s Desktop PCB Design tools require better connectivity to the outside world. eCADSTAR offers a newer level of connectivity that brings users closer to their parts providers than ever before. This allows Engineers to selected parts and drag them directly to their design. Add the additional functionality of high power Signal integrity verification and Power integrity analysis and you have the Ultimate Desktop PCB Engineering solution.

- Products

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.