When it comes to Engineering Data Management Adoption, especially in industries like cable and harness design, people tend to fall into one of four distinct mindsets. These mindsets reflect how individuals and teams perceive the need for change—and whether they resist or embrace it.

We call them the Loathers and the Lauders.

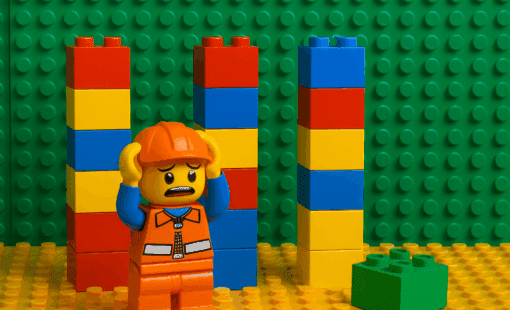

The Loathers: Resistant to Change

Loathers are those who resist adopting engineering data management systems. They typically fall into two categories:

- Optimists – These individuals believe their current systems are working just fine. They don’t see the need for change because they haven’t yet experienced a significant failure. Unfortunately, this mindset often overlooks the subtle cracks forming in workflows, cracks that can lead to costly disruptions.

- Deniers – These are people who have experienced a failure—lost files, version confusion, or compliance issues—but dismiss it as a one-time fluke. They’re reluctant to invest in a solution because they believe it won’t happen again. This mindset can be risky, especially in complex environments such as cable and harness design, where data integrity is critical.

Loathers often raise objections like:

- “Our current system works fine.”

- “It’s too expensive.”

- “It’ll slow us down.”

- “We don’t have time to implement it.”

But these objections rarely hold up under scrutiny. The cost of inaction—downtime, rework, compliance penalties—can far exceed the investment in a proper engineering data management system.

The Lauders: Advocates for Preparedness

Lauders are those who understand the value of engineering data management and actively support its adoption. They include:

- Proactives – These individuals anticipate potential issues and take steps to prevent them. They see engineering data management as a strategic investment that improves collaboration, ensures compliance, and facilitates scalability.

- Veterans – These are people who have lived through data disasters and emerged wiser. They’ve experienced the pain of poor data management and now champion robust systems that protect against future failures.

Lauders know that the extra steps and upfront investment are worth it. They’ve seen the benefits of proper data management:

- Prevents costly mistakes

- Enables faster decision-making

- Supports scalable growth

- Enhances product quality and traceability

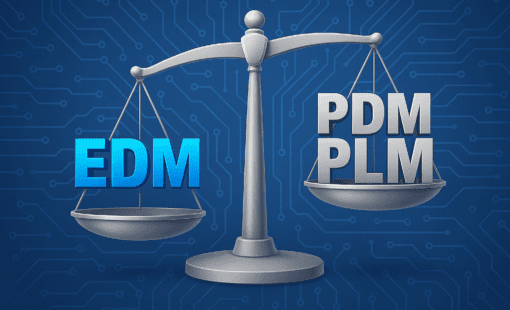

Key Benefits of Engineering Data Management Adoption

- Improved Data Integrity – Centralized, version-controlled data reduces errors.

- Faster Retrieval – Engineers spend less time searching and more time solving.

- Disaster Recovery – Reliable backups minimize downtime.

- Compliance Readiness – Traceable data streamlines audits and regulatory compliance.

- Collaboration and Scalability – Teams work together more effectively, even remotely.

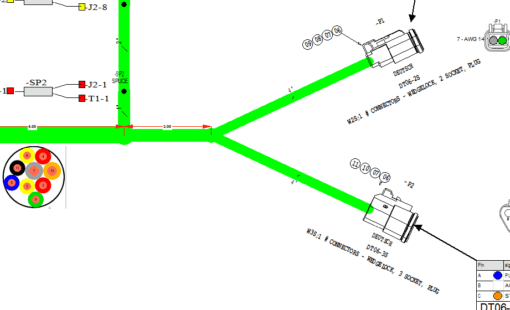

- Design Accuracy – Especially vital in cable and harness design, where managing revisions and configurations is critical.

Zuken’s DS-E3: A Proven Solution

For teams ready to move from loathing to lauding, Zuken’s DS-E3 offers a robust, scalable solution tailored for cable and harness design.

DS-E3 provides:

- Centralized data management

- Real-time collaboration

- Full traceability and compliance support

- Disaster recovery capabilities

- Integration with PLM, ERP, and other enterprise systems

Whether you’re just starting your journey or recovering from past failures, DS-E3 helps teams confidently manage engineering data and unlock long-term value.

Ready to move from loathing to lauding? Contact us to learn how Zuken’s DS-E3 can help your team streamline engineering data management.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog