In engineering and manufacturing, managing design data isn’t just about storage. It’s about control, collaboration, and continuity. While Product Data Management (PDM) and Product Lifecycle Management (PLM) systems often steal the spotlight, Engineering Data Management (EDM) systems quietly deliver focused benefits that keep engineering teams productive and precise.

This post compares EDM vs PLM, shows where EDM fits alongside PDM, and explains why it matters for engineering success.

EDM vs PLM: Understanding the Difference

| System | Primary Focus | Key Benefit |

| EDM | Managing technical documents (CAD files, drawings) | Streamlined control over native engineering data |

| PDM | Managing product-related data (CAD, BOMs, revisions) | Structured data management during development |

| PLM | Managing the entire product lifecycle | Strategic collaboration across the enterprise |

EDM systems are purpose-built for engineering teams who need to manage CAD files, drawings, and technical documentation with precision. They simplify workflows, reduce errors, and maximize control without the complexity of enterprise-wide PLM.

Benefits of EDM Systems

Precision Document Control

EDM systems excel at managing complex engineering files like CAD drawings. They ensure version accuracy, prevent data loss, and reduce costly design errors.

Seamless CAD Integration

Unlike PLM tools, EDM systems connect directly with CAD design software. Engineers stay within their familiar design tools with no need to switch platforms. Native integration boosts productivity and reduces friction in design processes.

Efficient Design Reuse

PDM and PLM systems lack granularity necessary to handle design data to drive reuse. With EDM, validated designs and components can be reused across projects. EDM accelerates development and maintains consistency across product lines.

Full Traceability

EDM systems track changes, revisions, and user actions, providing audit-ready documentation. This documentation is essential for regulated industries and quality assurance. In practice, EDM tracks work-in-progress design changes, while PDM manages released documentation.

Case Study: DS-E3 in Action

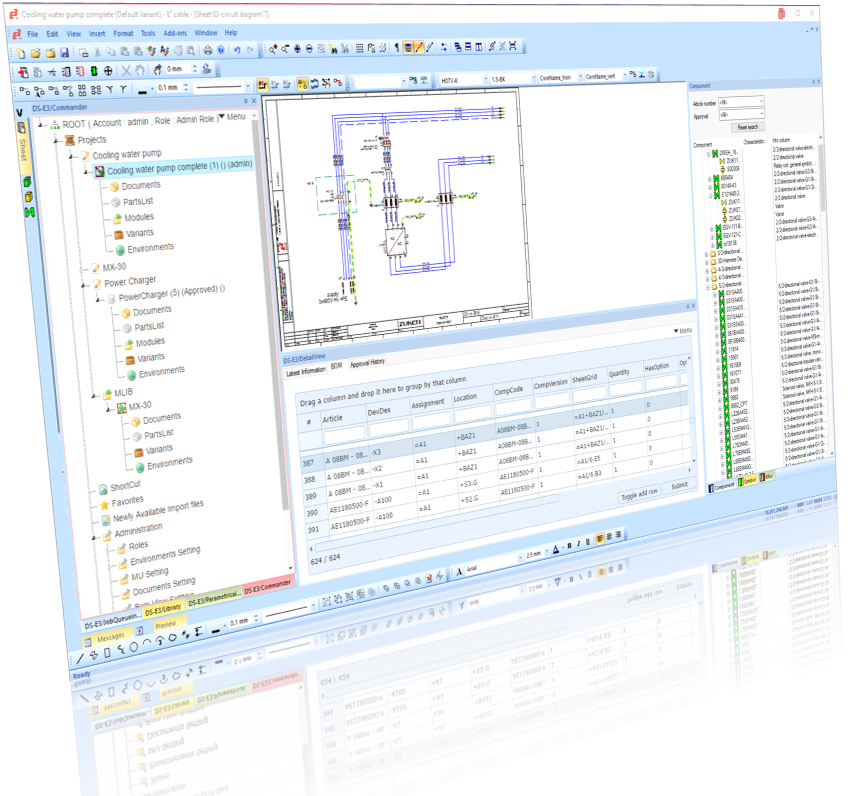

Zuken’s DS-E3 is a standout example of how an EDM system enhances engineering workflows:

- Native Data Management

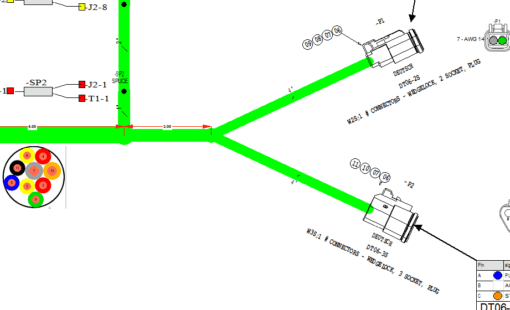

Built on the E3.series model, DS-E3 manages electrical designs at the project level, storing both saved and approved versions. Engineers can version entire designs, individual sheets, or devices—giving visibility beyond traditional data management systems.

- Design Control

DS-E3 supports wire harness, cable, control system, and fluid design data. Versioning and change management can vault work-in-progress copies for full traceability during development.

- Enterprise Workflow Integration

EDM does not replace PDM or PLM. Instead DS-E3 integrates with PLM and ERP systems like Siemens Teamcenter, Dassault 3DEXPERIENCE, and SAP to ensure enterprise-wide continuity.

- Component Visibility

Engineers can instantly see where parts are used, supporting sourcing decisions and impact analysis.

When to Choose EDM vs PLM

Choosing the right data management system depends on your team’s priorities, workflows, and long-term strategy. When considering EDM vs PLM/PDM, here are four key scenarios where EDM stands out as the right choice:

- You manage CAD files and technical drawings daily.

- You need version control and design reuse without the overhead of full PLM.

- Your team wants to stay within their CAD environment while maintaining data integrity.

- You’re preparing for future PLM integration but need a dedicated engineering solution today.

If any of these scenarios sound familiar, it may be time to consider EDM as a complement to PLM and PDM.

Conclusion: Why EDM Matters

The EDM vs PLM discussion is not about choosing one over the other. EDM focuses on engineering precision, while PLM handles enterprise-wide lifecycle needs. Together, they create a stronger digital thread that improves collaboration, reduces errors, and supports innovation.

Zuken’s DS-E3 empowers engineering teams to take control of design data and connect seamlessly with enterprise systems.

👉 Next step: Contact us and mention “Data Management” to learn how DS-E3 can streamline your workflows.