As the hangover from the COVID era continues to impact the supply chain, reducing design time and getting products to market more quickly is more important now than ever before. Adopting a Design for Manufacturing (DFM) approach is essential. Likewise, addressing Design for Manufacturing considerations early in the design process is key to achieving these gains. At PCB West next month, we’ll show three of our latest technology solutions. These solutions help you realize your products quickly and efficiently while incorporating a robust DFM approach.

Efficient FPC Panels

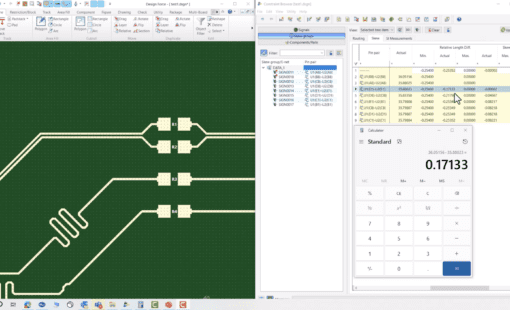

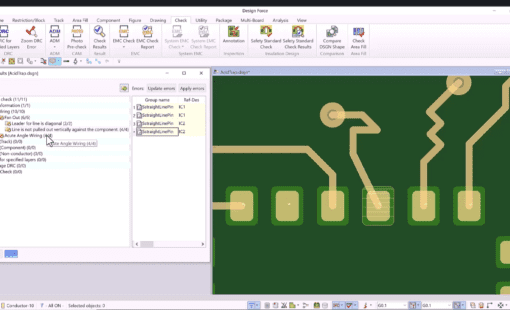

First, we’ll explore DFM Center FPC Panel Optimization tool. This is a new tool whose development includes customer feedback at its core. This tool allows an OEM or manufacturer to quickly analyze and evaluate multiple flex nesting configurations based on the parameters of the panel in use. In addition, the user can evaluate variations of different flex outlines to ensure maximum usage of the available panel space.

How does this affect time to market? It ensures a minimum of back and forth between the OEM and the manufacturer. As you might expect, this works even better when these partners are utilizing this tool collaboratively. It also has the additional benefits of ensuring the most efficient utilization of the panel space to address the continued difficulties in the material space. At the same time, it also ensures that Design for Manufacturing requirements are considered and met. This tool relies on common data formats to ensure it’s EDA tool-agnostic.

Ensuring Producibility

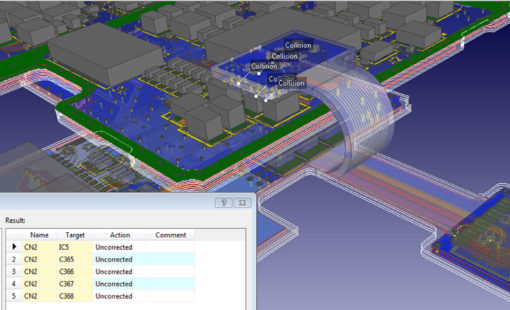

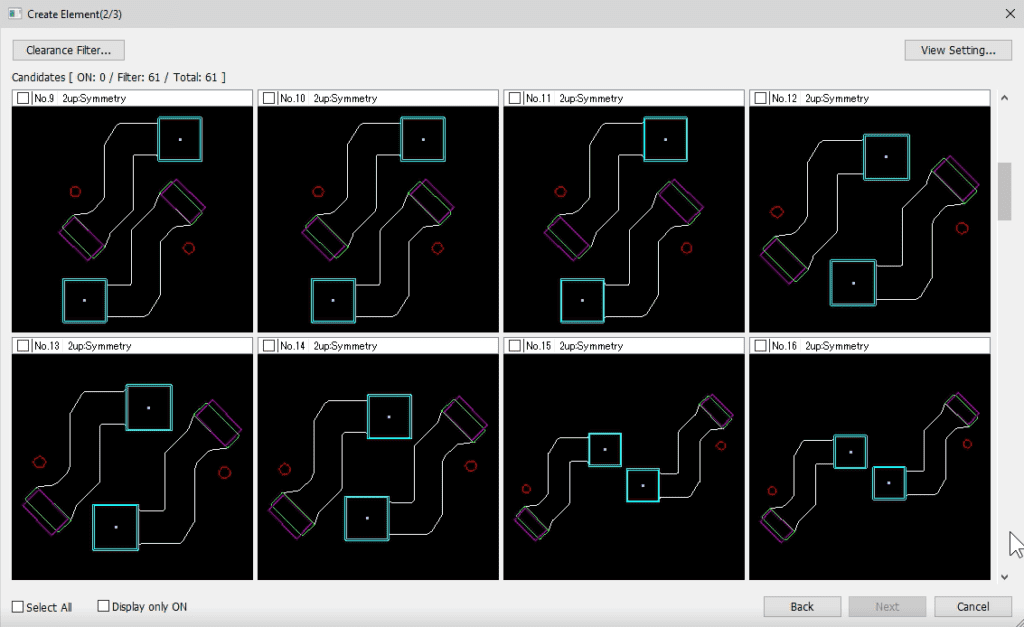

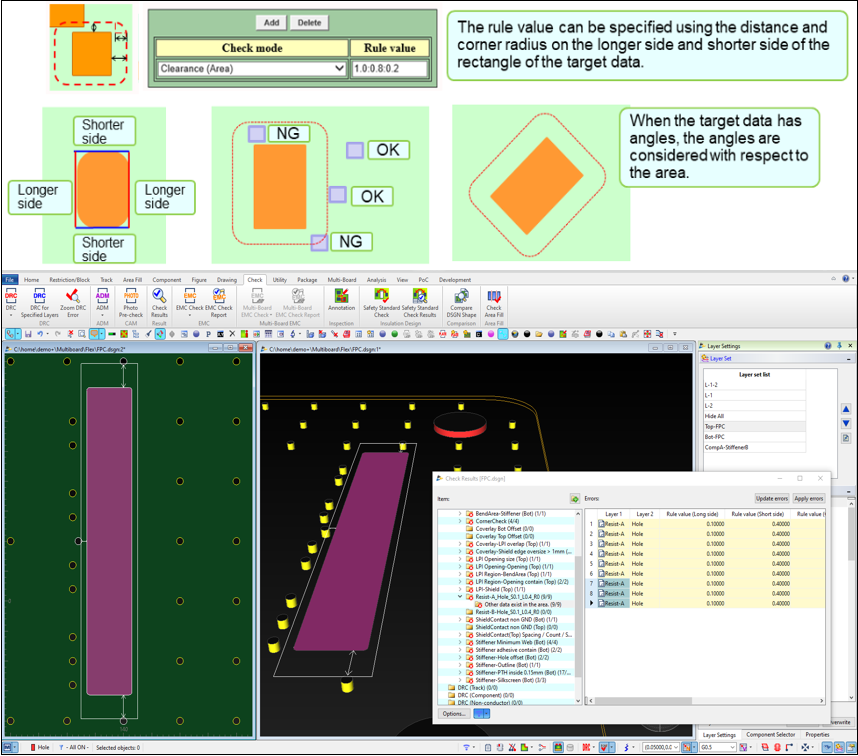

Next, we’ll take an up-close look at our Advanced Design for Manufacturing (ADM) tool offering advanced flex checking capability. ADM has a deep level of customization that ensures you can design your flex PCB products in line with your manufacturer’s DFM specifications. By leveraging these advanced rules, the designer can run evaluations at various points in the design process to minimize the impact of changes. These evaluations ensure that schedules are met and pave the way for a smooth transition to manufacturing.

As you may know, changes at the back end of the design process are most impactful and can upset budgets and schedules. ADM allows you to share rules amongst the various partners in your design process, keeping all parties on the same page. Initially, ADM was native to our CR-8000 products. However, we now offer an unplugged version of this powerful tool, making it compatible with virtually all EDA design tools.

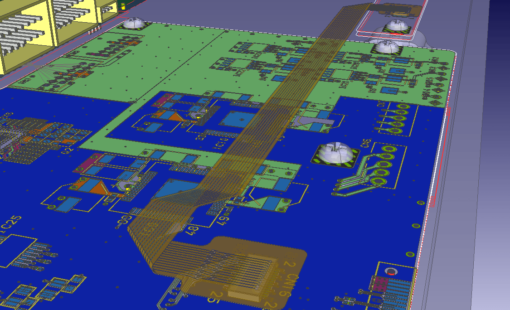

Integrated Design Environment

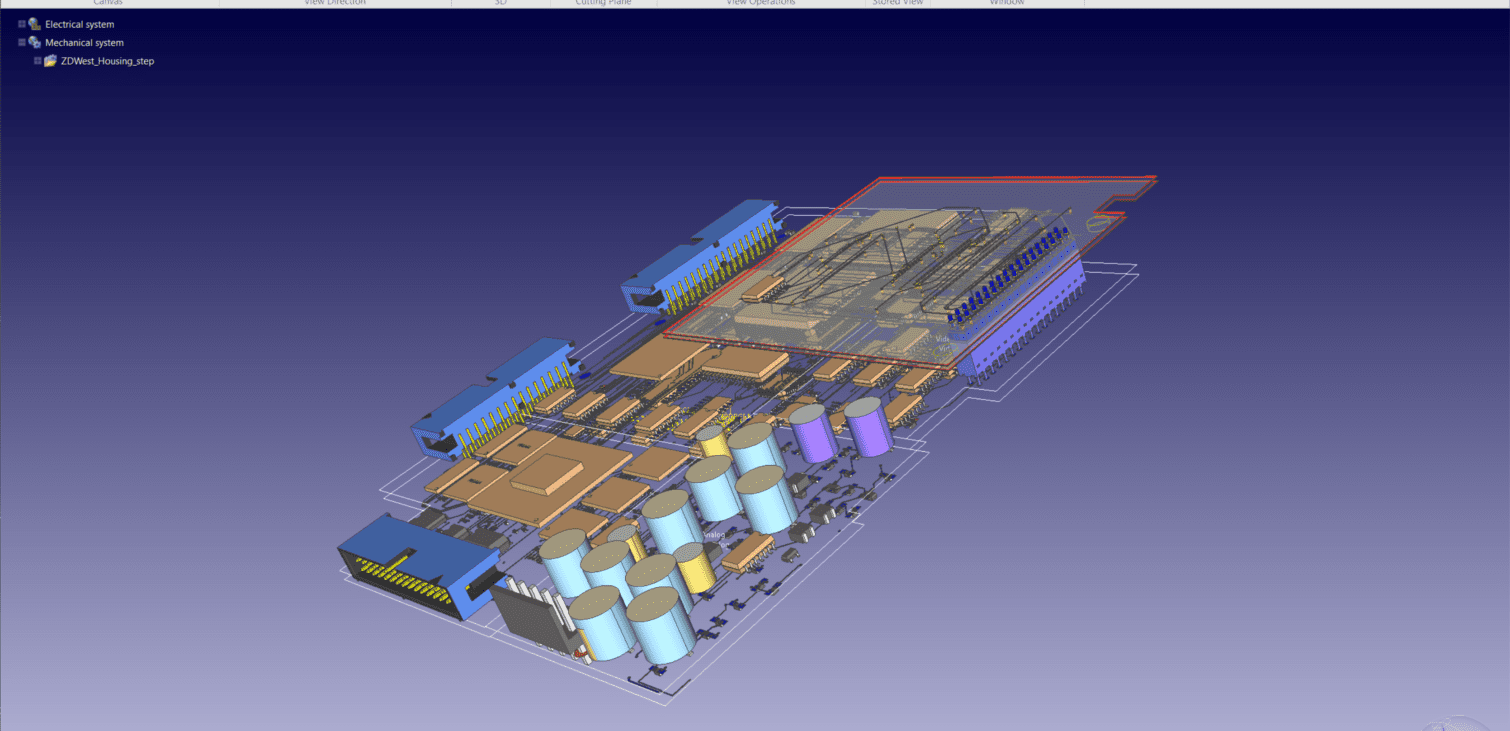

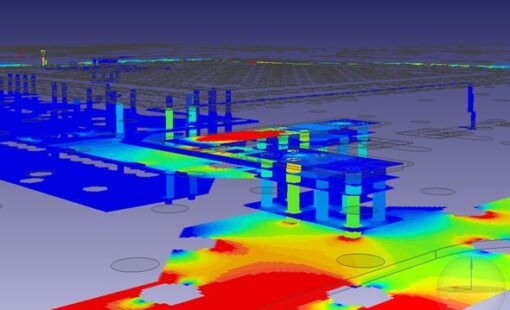

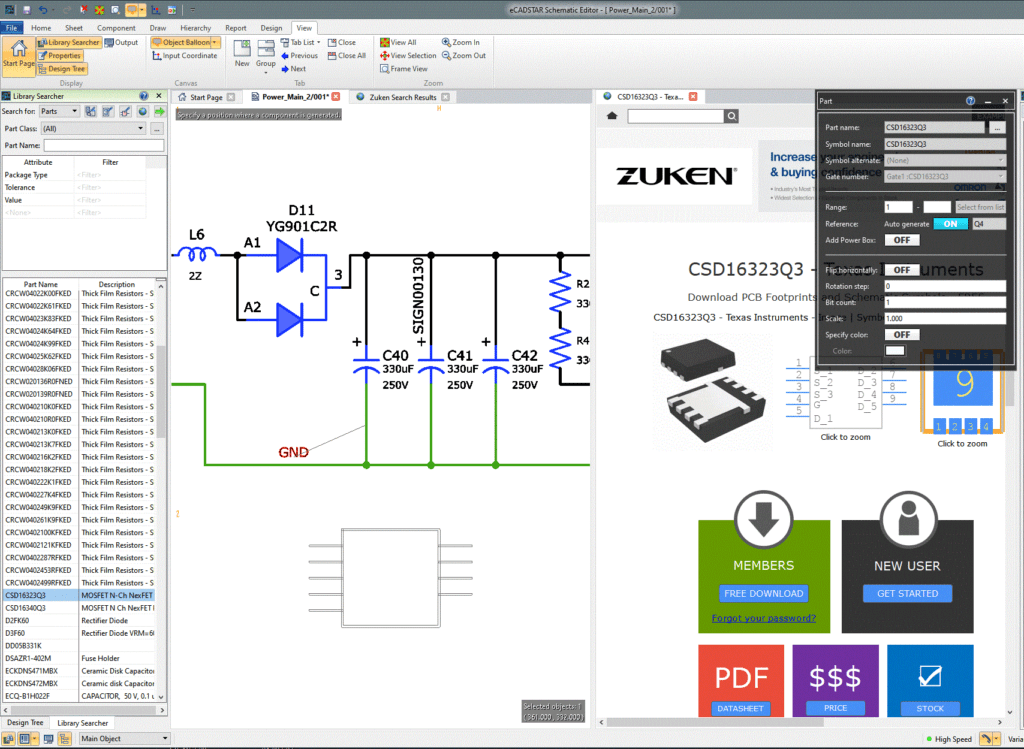

Last but certainly not least, we will highlight all the new and improved capabilities in our eCADSTAR desktop design tool. eCADSTAR combines routing, SI, and 3D MCAD collaboration into a single cohesive product. It’s everything you’d expect in a desktop PCB design tool, and then some. The integrated nature of the tool ensures that the user benefits from a robust, highly capable design environment. eCADSTAR offers an interactive tour and free DIY training and support using the built-in web browser, all in an intuitive user interface.

Notably, eCADSTAR also has the added benefits of direct connections to many supply chain partners for library creation, component metadata, as well as the ability to check cost and availability. These features ensure a seamless path between design and build, which is critical in today’s reality of continued component shortages. In many cases, you can simply design around the shortage and get the product to market as quickly as possible while addressing Design for Manufacturing and Design for Assembly considerations.

Learn More

Do not underestimate these issues or their potential impact on your design cycle. All the technologies mentioned in this post directly correlate to ensuring time-to-market, productivity, and efficiencies are top of mind throughout the design process. Visit us in Booth #500 at PCB West to learn more about these various technologies and how Zuken can help you establish a solid Design for Manufacturing approach.

Related Products and Resources

- Products

- Products

PCB Design for Manufacturing (DFM) enables designers to handle the increasing complexity and diversity of today’s PCBs, while ensuring high final product quality, and accurate outputs for the manufacturing processes. With a robust set of features for data preparation and embedded verification to ensure manufacturing specifications are met...