Why Electrical Design Must Evolve for High-Density AI Workloads

The AI transformation is here. There’s a tremendous need for engineering and expertise as data centers multiply worldwide. While AI chips and algorithms get the headlines, the challenge of supplying enough data center power often goes unnoticed.

Power systems engineers aren’t just creating new technology; they’re rethinking how they build it. Rising power densities, tighter footprints, and faster deployment cycles are reshaping the power distribution industry. Smarter, integrated approaches are no longer optional; they’re essential for the AI era.

What Makes AI Data Center Power Different From Traditional Data Centers

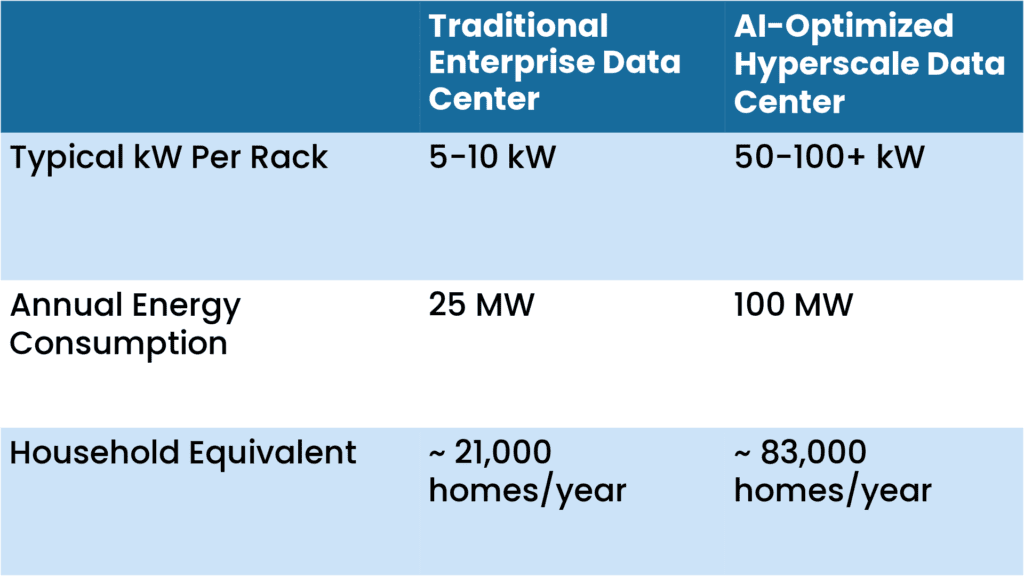

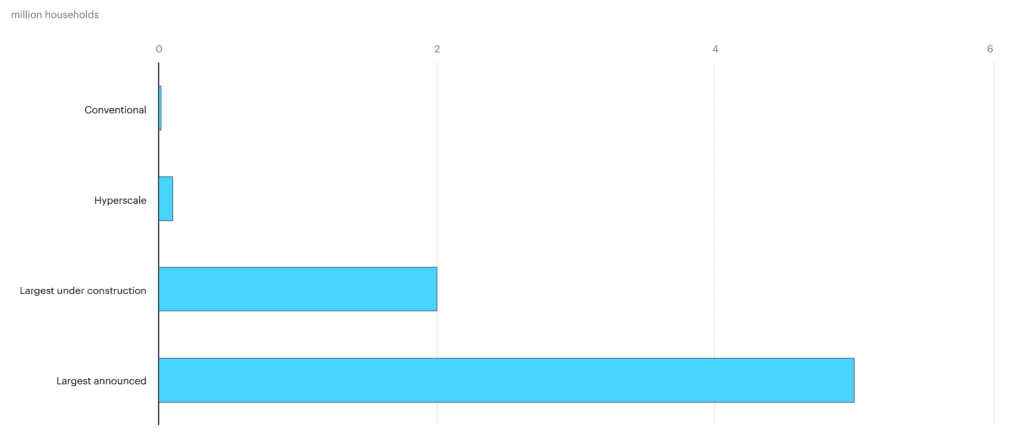

AI data centers draw more power to handle complex computations. They use parallel processing across thousands of GPUs to meet the near-instant demand of thousands of requests every second. Data centers optimized for AI consume far more power than traditional data centers.

AI data centers create recurring, immense spikes in power demand unlike any other application. These spikes force power systems to handle rapid load changes without compromising reliability. These data centers utilize cutting-edge power control systems with increased monitoring, specialized high-density circuit breakers, and dynamic load balancing.

Challenges for Power Engineers in the AI Era

AI data centers don’t just use more power; they change how power systems behave. High rack densities and sudden load spikes stress traditional distribution designs. Engineers must manage rapid load changes without tripping protection or overheating equipment.

The industry struggles with outdated practices. Big Tech drives aggressive timelines and backs them with massive budgets. Constantly evolving technology makes late-stage design changes inevitable. Expertise is scarce, yet companies must scale teams fast with minimal time to train. Traditional processes can’t keep up with this pace, leaving engineers scrambling to deliver accurate designs under pressure.

Electrical Design Methods are Evolving

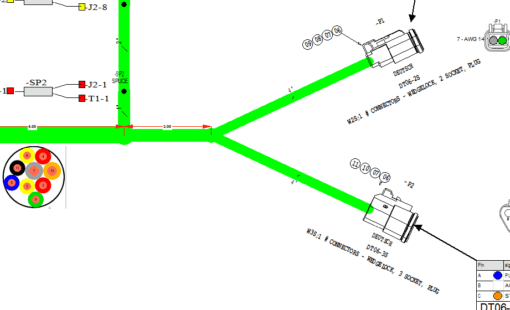

Engineers once relied on static schematics, manual BOM updates, and disconnected CAD files. Those methods create design errors in a world of rushed timelines, late-stage changes, and inexperienced engineers.

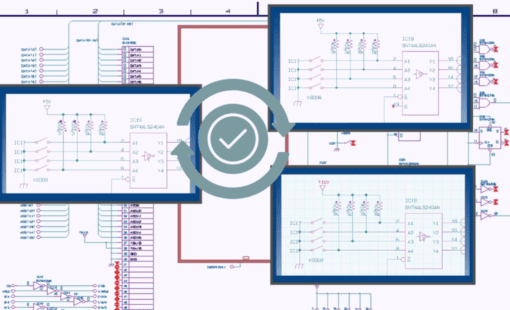

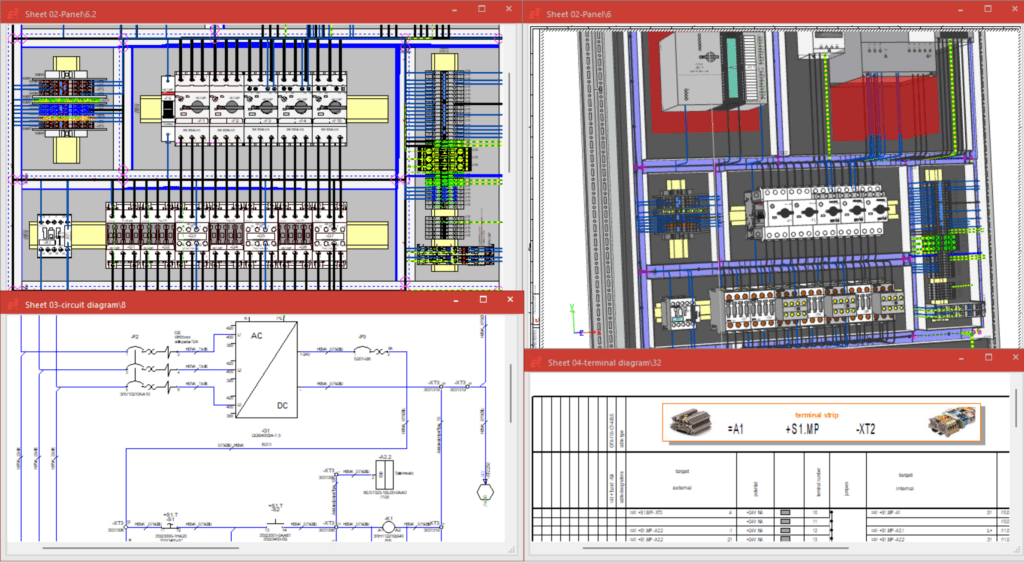

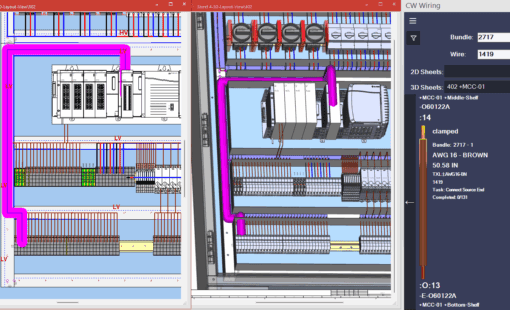

Modern projects demand connected design environments. Electrical, mechanical, and software teams now collaborate via live data models, eliminating the need for PDFs and spreadsheets. Design automation handles wire numbering, device tagging, and panel layouts, while integrated validation catches errors before they hit the shop floor. Engineers can focus on the big-picture design and engineering by leveraging integrated design platforms to see the details.

E3.series: Smarter Solutions for the Modern Age

Designing for AI-scale data center power systems requires smarter processes. E3.series synchronizes electrical schematics, physical panel layouts, and manufacturing outputs in one design environment. Engineers can validate connectivity, generate accurate reports, and drive design reuse to accelerate design with error-free confidence.

Next Steps

Ready to explore smarter electrical design for AI-scale power? Here are some resources to help you go deeper:

- Explore the E3.series product page

- Learn how E3.panel optimizes electrical panel design

- Watch this webinar on modern panel manufacturing strategies

Reference Links:

- Load of Azure AI data center

- Pew Research article

- Chart for IEA

- Blog

- Blog

- Blog