Define and track component versions through the library’s lifecycle

Zuken’s engineering data management platform DS-CR has been created to support the specific demands of PCB design data management. It combines multi-site library, design data and configuration management into a unified engineering environment.

Define and track component versions through the library’s lifecycle

Track component versions through the component lifecycle

Manage design data, related documents, simulation data, enclosures, parts lists and CAM data

Create comprehensive design information and documents to ensure a controlled change process

See how to get back time for thinking and designing and spend less time on administrative tasks

Find out more about Zuken's advanced library and design data management solutions

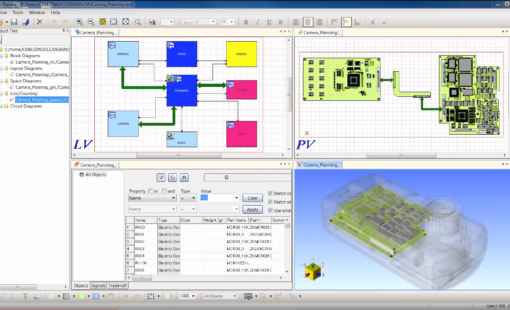

DS-CR is an Engineering Data Management (EDM) environment that has been designed to support the specific requirements of PCB and multi-board design. DS-CR is built on an object-oriented industry standard database and runs on Windows® based clients. It is directly embedded into the user interface in Zuken’s CR-8000 PCB Design environment, within the Design Gateway and Design Force authoring tools.

DS-CR’s component version and revision management functionality provides definition and tracking of versions of components and design data throughout the product lifecycle. Only valid component changes are distributed, preventing invalid or incomplete changes from being deployed.

DS-CR provides a central source of information by unifying all engineering data into one environment, and controlling synchronization to local or geographically-distributed development teams. DS-CR also supports the creation of modular circuit block libraries that can be retrieved and re-used in new designs, saving valuable engineering time and money. If single components need be updated because of sourcing issues, all instances will be automatically identified in “where used” analyses.

A built-in change management process provides a detailed documentation of each design or document change, such as modifications to the specification, customer change, and obsolescence.

By unifying all engineering data into one environment and controlling synchronization to local or international development teams, DS-2 provides a single source of truth in a global environment.

DS-CR has been designed to enhance existing PLM systems – not to replace them. DS-CR can integrate with all major PLM and ERP systems and provides SOA-based “plug & play” connectors; in addition, generic integration APIs are

available for other third party systems.

The integration between DS-CR and third party PLM environments is bi-directional and includes the synchronization of material data, the bill-of-materials information and related documents.

Zuken and SiliconExpert have partnered to deliver critical component information to engineers within the CR-8000 and DS-CR design and database environment. The integration enables engineers to make better component selection decisions, resulting in higher quality products and lower costs in less time.

Learn moreOur satisfied customers

see how DS-CR handles…

DS-CR provides analysis of where components are used and what second sources are defined. The engineer also has access to criteria available to rate second source components for their order of usage.

DS-CR provides in-depth analysis to maintain the best possible quality of library information before reusing libraries or its individual objects.

DS-CR provides a where-used search capability that shows where a component is being used, whether it is used by other assemblies, which revision of the assembly it is in, etc.

DS-CR offers a flexible way to rank components based on a customer’s matrix, to ensure valid methods for engineers to bridge the gap between engineering suppliers.

By combining the supplier information with technology, quality and source rating information, you can make an informed decision, considering all variables, to guarantee the right component is selected to deliver the best business results.

DS-CR provides BOM analysis based on a broad range of criteria, e.g. preferred vendor/supplier analysis; component technology analysis; component lifecycle analysis; price analysis; quality analysis; stock amount analysis; development and manufacturing approval analysis.

DS-CR is ideally suited to help with variant and destination management, while ensuring high levels of quality and reliability.

To guarantee permanent synchronization between component lists, material master and related schematic and layout files, DS-CR provides a four point comparison method to cover all changes of related information, within a single comparison result window.

DS-CR helps engineers to evaluate the recommended stress criteria of FMEA when de-rating electronic parts or components, and to define the maximum application stress values.

Preferred Parts Lists include components pre-approved for use within a company, division or a given project. A PPL actively promotes approved parts and supports accurate part selection and type reduction.

DS-CR supports the definition of data management analysis and design reuse plans for any given scenario: design data analysis and reuse; design data; archiving of verified design data for regulatory audits; design data access to allow users to work from any computer around the world.

Related products and solutions

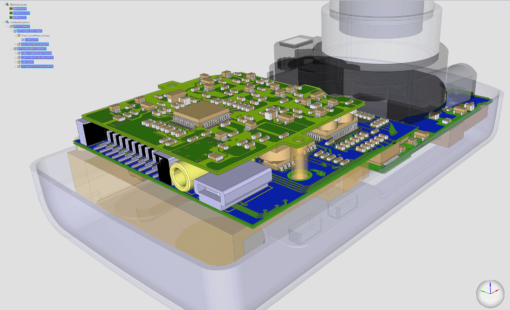

CR-8000 Design Force is the fastest, most effective PCB design solution available today. Design Force enables design teams to layout and verify their designs in the context of a complete system or product.

CR-8000 Design Gateway provides a platform for logical circuit design and verification of multi-board system-level electronic designs.

With a robust set of features for data preparation and embedded verification to verify manufacturing specifications, DFM Center addresses the challenges of the manufacturing process.

Related Resources

Find out more about DS-CR via our webinars, press releases and more...

Discover how Zuken’s CR-8000/DS-CR integrates with Dassault Systèmes’ 3DEXPERIENCE Platform, providing robust solutions for efficient data management and collaborative workflows between electrical and mechanical design teams.

Dans ce webinaire, un processus de conception de PCB optimisé combinant la technologie Zuken CR-8000 et les fonctionnalités d'optimisation du stack-up fournies par Polar Speedstack ™ sera présenté.

Travailler en toute sécurité - telle est la proposition de valeur de Pizzato Elettrica, une entreprise de sécurité industrielle bien établie basée à Marostica, en Italie. Elle a choisi Zuken pour mettre en œuvre une solution intégrant son environnement de conception électronique à l'infrastructure PDM de l'entreprise.

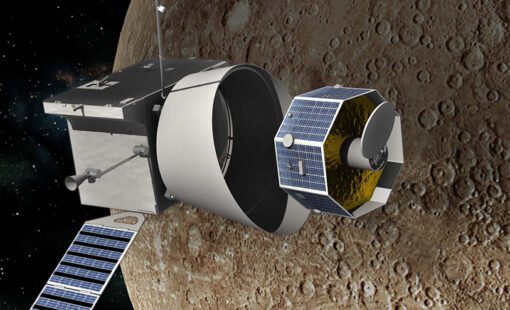

EREMS, a French enterprise specializing in the design and realization of high-tech electronic equipment and of associated software for Space, Defense, and Aeronautics uses CR-8000 and DS-CR from Zuken for the design and lifecycle management of flight electronics, ground electronic equipment, and test benches.

The integration enables data and metadata generated in Zuken’s systems to be used in company-wide business processes managed in SAP, such as concurrent engineering, module management, configuration management, component management as well as change and release management.