Zuken Announces a new Strategy for Streamlining Data and Workflow Management

18 May 2017 – Munich, Germany – Zuken announces a new strategy for increasing engineering productivity in the manufacturing sector, based on:

- A new, streamlined approach for managing electrical and electronic engineering data and processes, based on handling work-in-progress data within the ECAD environment.

- A new electrical data and workflow management solution, DS-E3, which joins Zuken’s existing portfolio of data management applications.

Christoph Leiterer, Head of Electrical and Software Engineering Tailormade, Stadler Rail said: “Receiving version-proof data from our electrical design team forms the basis of our optimized manufacturing process. Stadler has therefore decided to use DS-E3 for managing its electrical engineering work-in-progress data.”

Benjamin Nixdorf, Managing Director Europe, Zuken, said: “This new solution has the potential to boost productivity in many sectors, as it can meet the challenges of design reuse, configure-to-order, and electromechanical product development.”

A better approach to PLM

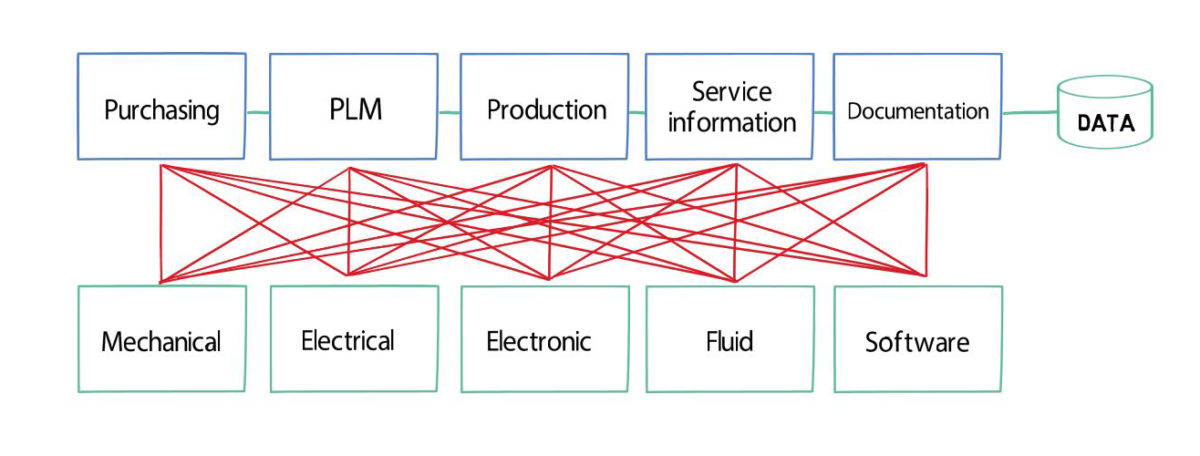

Increase productivity by reducing interfaces

The impetus for Zuken’s new approach is the number of companies spending increasing amounts on technology to cope with growing design complexity, coupled with the pressure to increase engineering productivity.

Receiving version-proof data from our electrical design team forms the basis of our optimized manufacturing process. Stadler has therefore decided to use DS-E3 for managing its electrical engineering work-in-progress data.

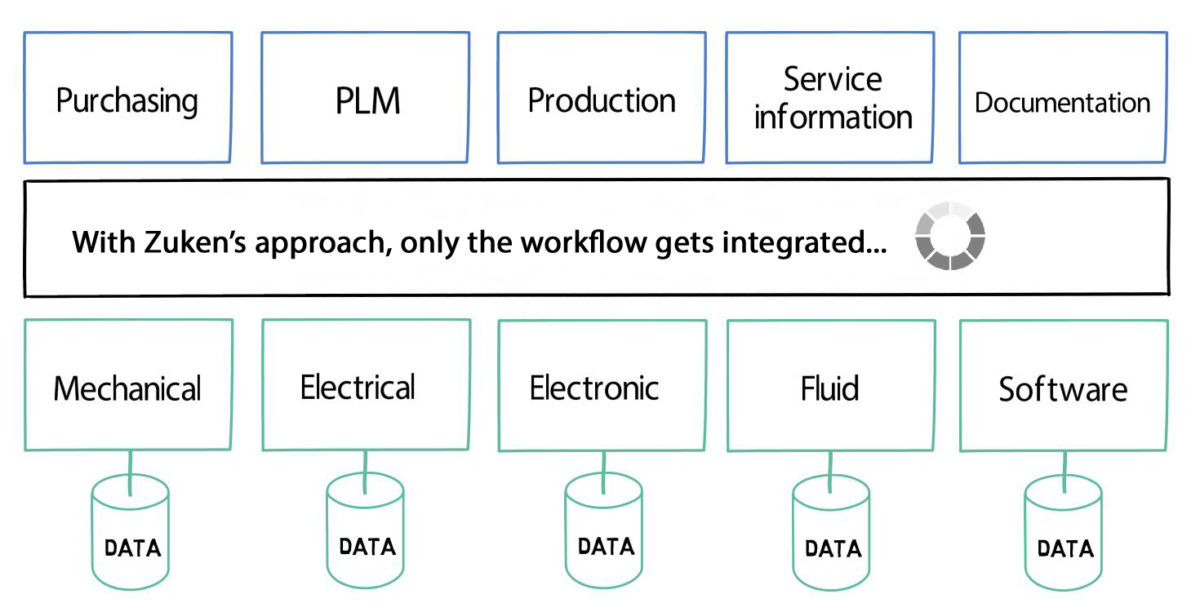

Zuken has challenged the assumption that it makes sense to hold all the interdisciplinary data and workflow information in one system. By managing work-in-progress data information within a discipline-specific environment, engineering processes are streamlined and synchronized with cross-discipline PLM and ERP systems.

Known as ‘domain data management’, this approach combats one of the main reasons PLM and other systems fail to provide the required depth of integration, take longer, and cost more than expected. Understanding the native ECAD data model enables design reuse, and offers the missing link that PLM, ERP and other systems need in order to run efficiently.

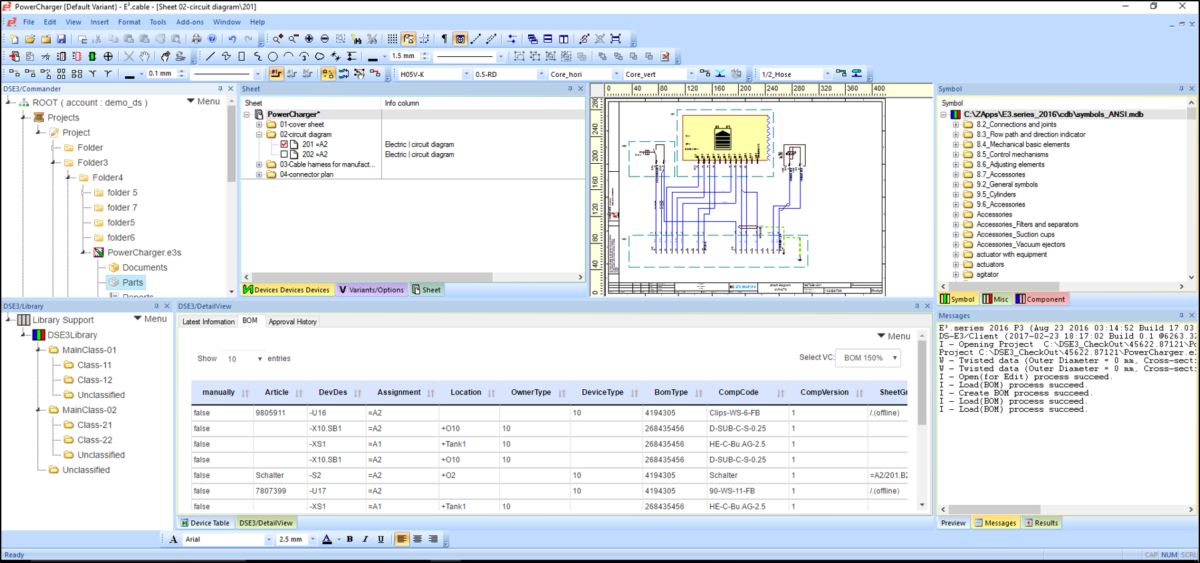

Direct integration increases productivity

Zuken’s new electrical data and workflow management solution integrates directly into Zuken’s E3.series suite for electrical and fluid design, so engineers do not need to leave their CAD application to carry out everyday tasks. Engineers can increase their productivity by reducing the number of individual applications and user interfaces they use.

DS-E3 is designed specifically for electrical design and manufacturing engineers. It provides them with current, validated material information and libraries, design data and BOM information to manage tasks and workflows for change and approval processes, and supports intelligent design configuration and reuse through module and variant management. The solution complements Zuken’s existing electronic data and workflow management tool, DS-CR, which embeds directly into Zuken’s CR-8000 suite for 2D/3D electronic design.

A proven history of data management

Zuken’s DS-2 is a mature, cross-disciplinary engineering data management platform developed in partnership with more than 3,000 leading companies worldwide. DS-2 has evolved from an electronics data management product into a technology platform capable of managing electronics design data from Zuken’s CR-8000 suite for 2D/3D electronic design (using DS-CR) and electrical data from E3.series (using DS-E3) embedded into their respective ECAD environments.

Zuken has been helping customers streamline their electrical, electronic and fluid engineering product development processes for more than 40 years. For more information, see www.zuken.com/edm

– ends –