Zuken makes electrical designs come alive and identifies errors

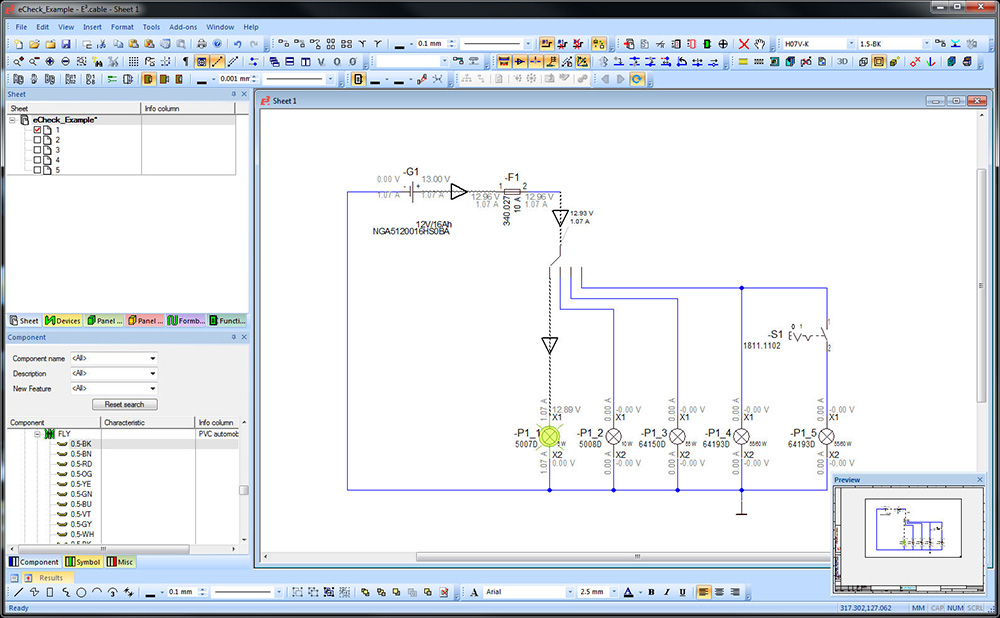

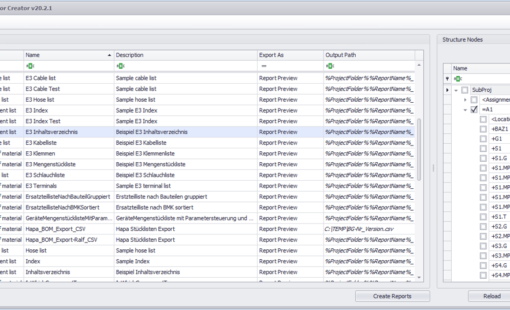

10 September 2013 – Munich, Germany and Westford, MA, USA – Zuken announces a new product for electrical design that identifies errors at the development stage and avoids costly iterations. E3.eCheck – part of Zuken’s E3.series industry-leading electrical and fluid CAD software – automatically ensures the schematic is functionally accurate and that wires and fuses are within the acceptable tolerances. The design analysis runs in real-time and replaces time-consuming manual checks.

New E3.eCheck productivity product

“E3.eCheck represents an advancement in the tools available for electrical engineering of harnesses and control systems,” said Steve Chidester, head of international marketing at Zuken. “The days of prototyping and then documenting afterwards are on their way out. Today it is important to engineer products from concept through manufacturing. E3.eCheck not only makes design analysis faster and more accurate, but it also identifies design flaws early – saving time and cost by eliminating prototype iterations.”

Designs come to life

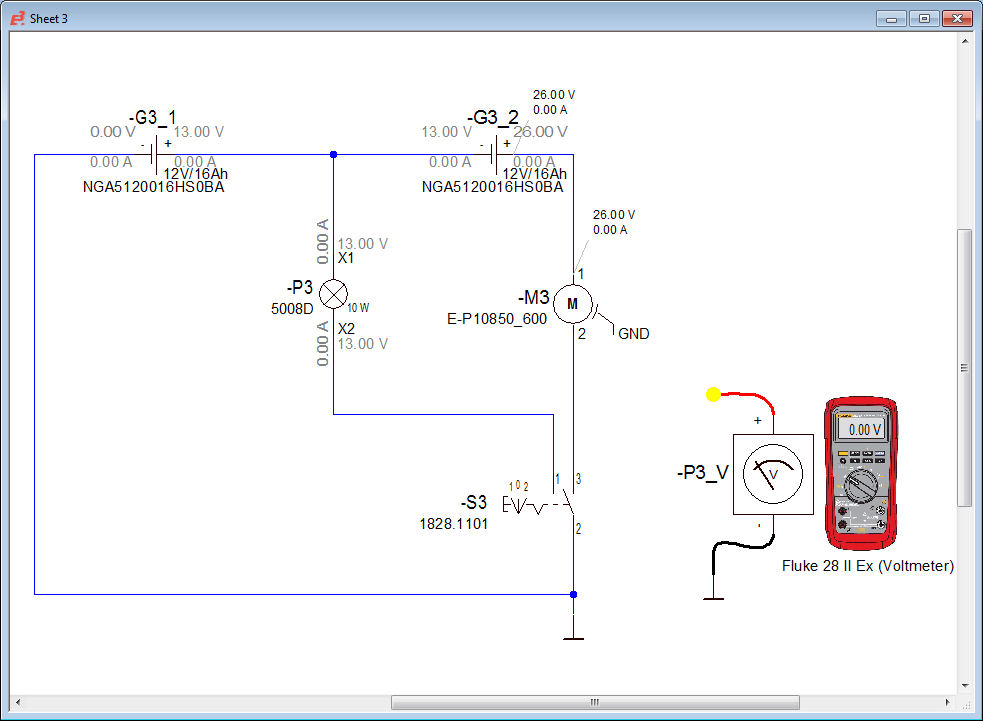

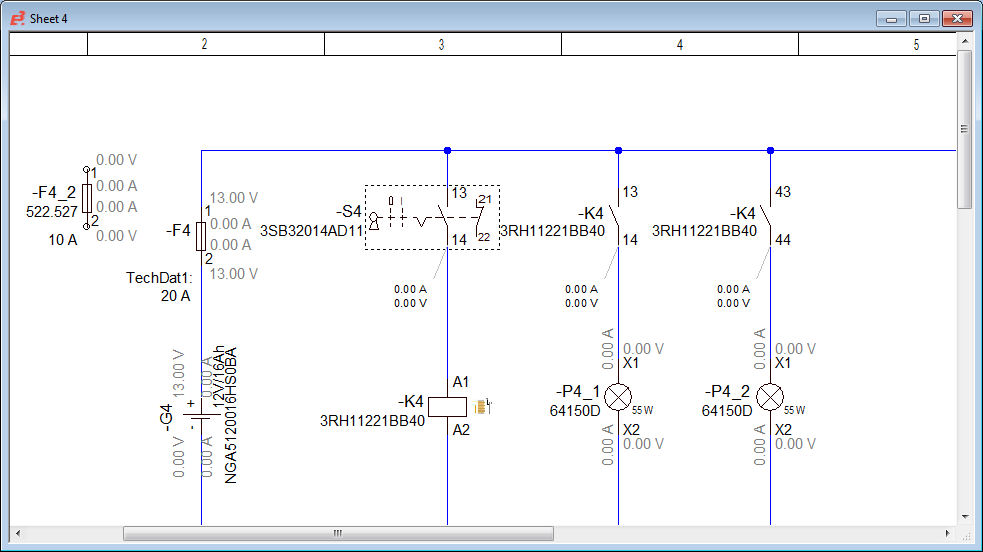

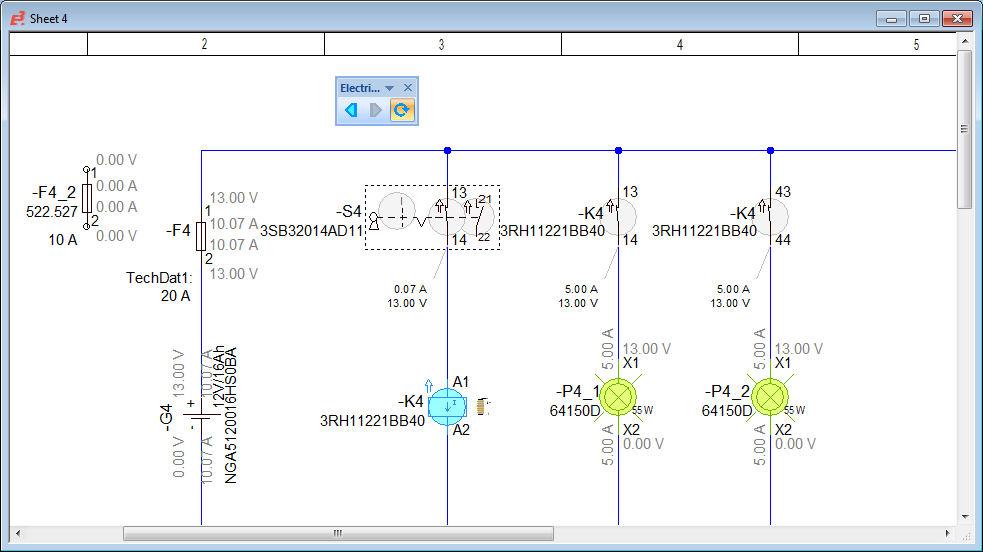

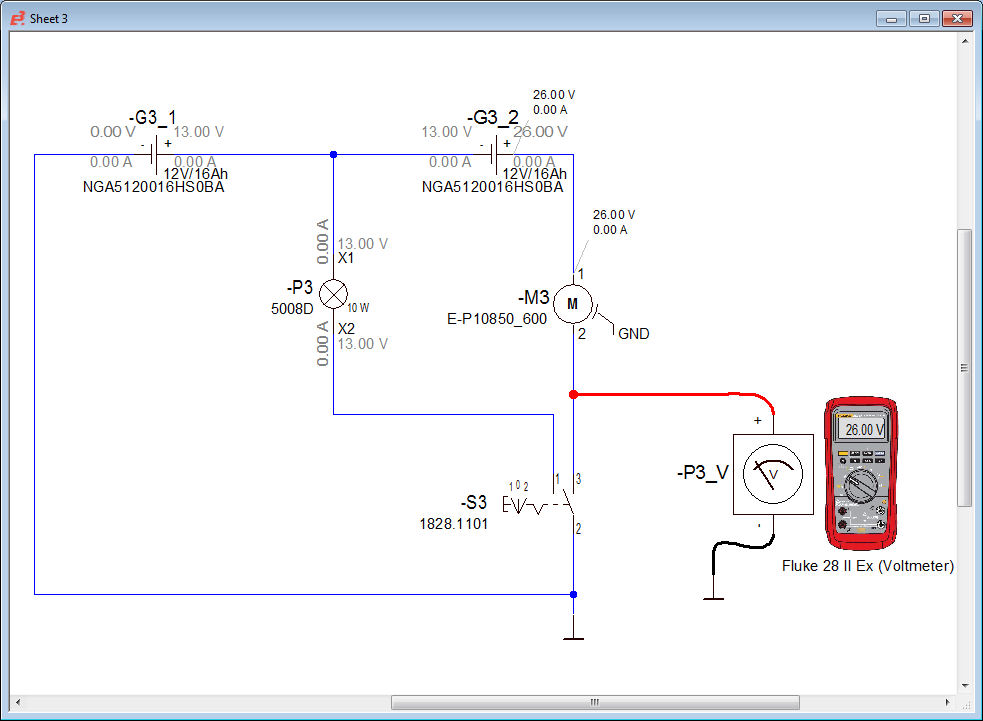

As well as catching tolerance design faults, E3.eCheck also simulates functionality checks bringing electrical schematics to life. Operating a switch simulates current flow through the circuit, opening and closing contacts or energizing coils, which in turn operate additional contacts. As the current flows through the circuit, loads activate or de-activate and provide immediate visual and audible feedback to the user on their behavior and operational accuracy. This ability to check real-world situations means engineers achieve enhanced design quality.

Tests include: DC checks, current direction, voltage drop analysis, fuse sizing, load checking and default wire settings.

Avoid over-engineering

Another benefit is the ability to optimize wire gauges to save costs on copper, avoiding the tendency to over-engineer when using manual calculations. Improved design accuracy also means higher product quality and a reduction in recall costs, damage to brand reputation and improved customer satisfaction.

This product will benefit users across a broad range of industries, but was developed particularly for users in the off-highway and special vehicles, automotive, aerospace and machinery sectors.

For more information see www.zuken.com/e3-series or E3.eCheck web page.

– ends –