Zuken Partners with Nano Dimension to Develop Seamless Design to Manufacture for 3D Printing

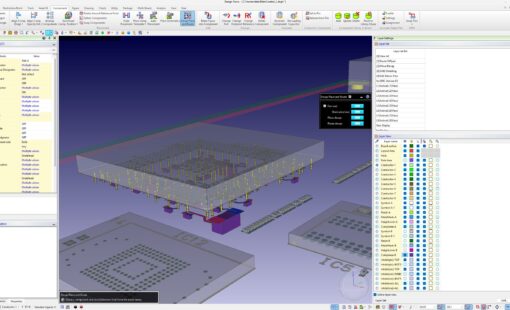

5 April 2017 – Westford, MA, USA – Zuken and Nano Dimension are working together to advance the 3D printing user experience and prototype turnaround times. Nano Dimension, a leader in electronic printing technologies, will take advantage of the support for implementing electronic technologies provided by Zuken’s market-leading, native 3D, system-level design solution, CR-8000 Design Force.

We’re excited about working with Zuken to harness Design Force and take our products even further, giving our users a seamless experience from design to output and optimization.

Simon Fried, Chief Business Officer, Nano Dimension, said: “It has been an amazing few years for our company as we’ve fielded interest in our technology. We’re excited about working with Zuken to harness Design Force and take our products even further, giving our users a seamless experience from design to output and optimization.”

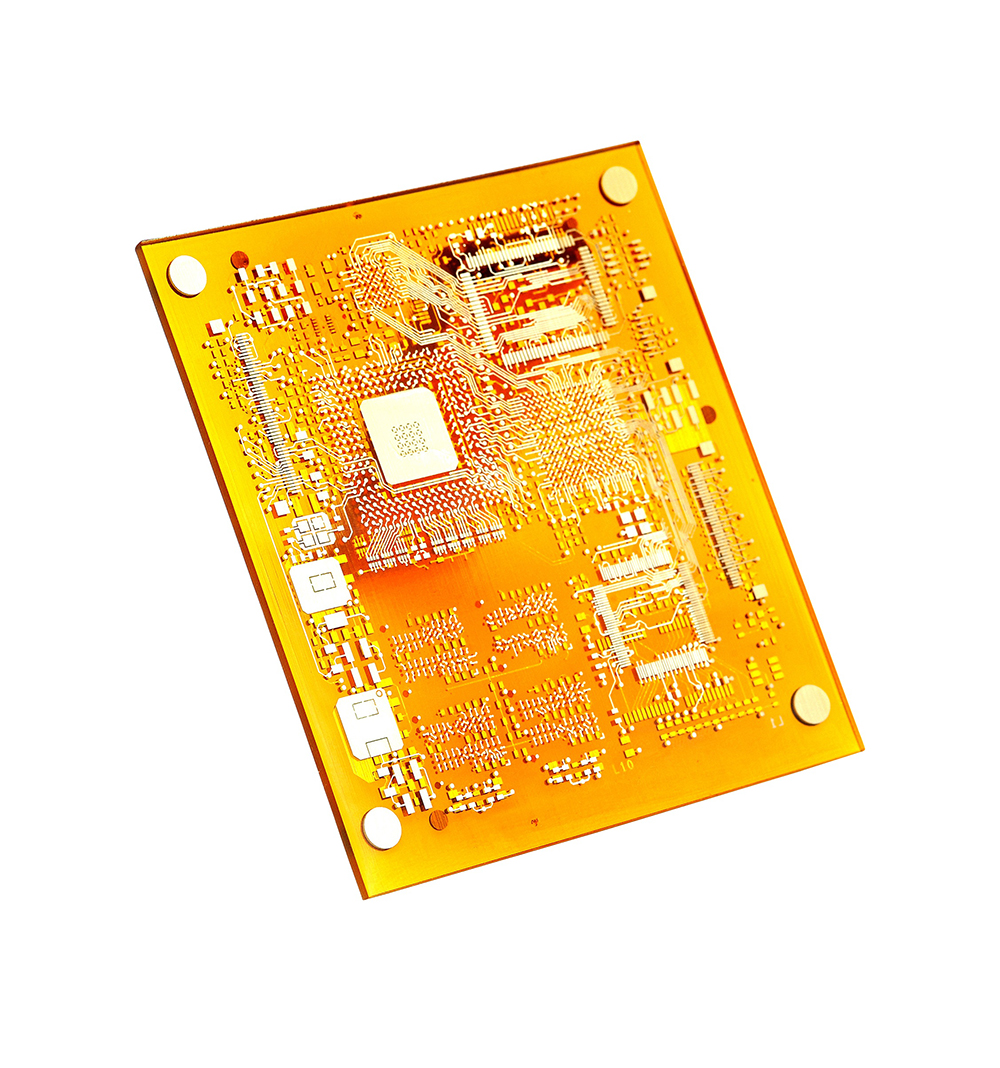

Nano Dimension develops advanced 3D printed electronics platforms, including the DragonFly 2020 3D printer for multilayer printed circuit boards, and nanotechnology-based conductive and dielectric inks for their 3D printers. The printer continues to capture global industry and media attention. Future developments will see expansion to support additional board technologies including flexible circuits and embedded components.

Humair Mandavia, Chief Strategy Officer, Zuken USA, said: “Zuken’s CR-8000 Design Force retains all the detailed data needed for 3D printing and allows export direct to manufacturing or 3D printing, without losing integrity. Nano Dimension’s 3D printers are typical of the many applications we envisioned when we pioneered native 3D design for manufacturing.”

Design Force is the sole design tool that allows specification of unique rules for materials, meaning no extra steps are needed when 3D printing to silver and any other future conductive material. Zuken also offers dedicated DFM solutions to support printed electronics via its DFM Inkjet module that optimizes CAD data for inkjet printers. With these solutions from Nano Dimension and Zuken users can expect to spend more time innovating and getting new ideas to market, rather than dealing with design administration.

DragonFly 2020

Nano Dimension's 3D Printing Platform For Electronics

About Nano Dimension

Nano Dimension Ltd. (NASDAQ, TASE: NNDM), founded in 2012, is focused on the research and development of advanced 3D printed electronics, including a 3D printer for multilayer printed circuit boards, and the development of nanotechnology-based conductive and dielectric inks, which are complementary products for 3D printers. Nano Dimension’s novel and proprietary technologies enable the use of conductive and dielectric inks for ultra-rapid prototyping of complex, high-performance multilayer circuit boards. The company’s PCB 3D printer is the result of combining advanced breakthroughs in inkjet technology, 3D printing and nanotechnology.