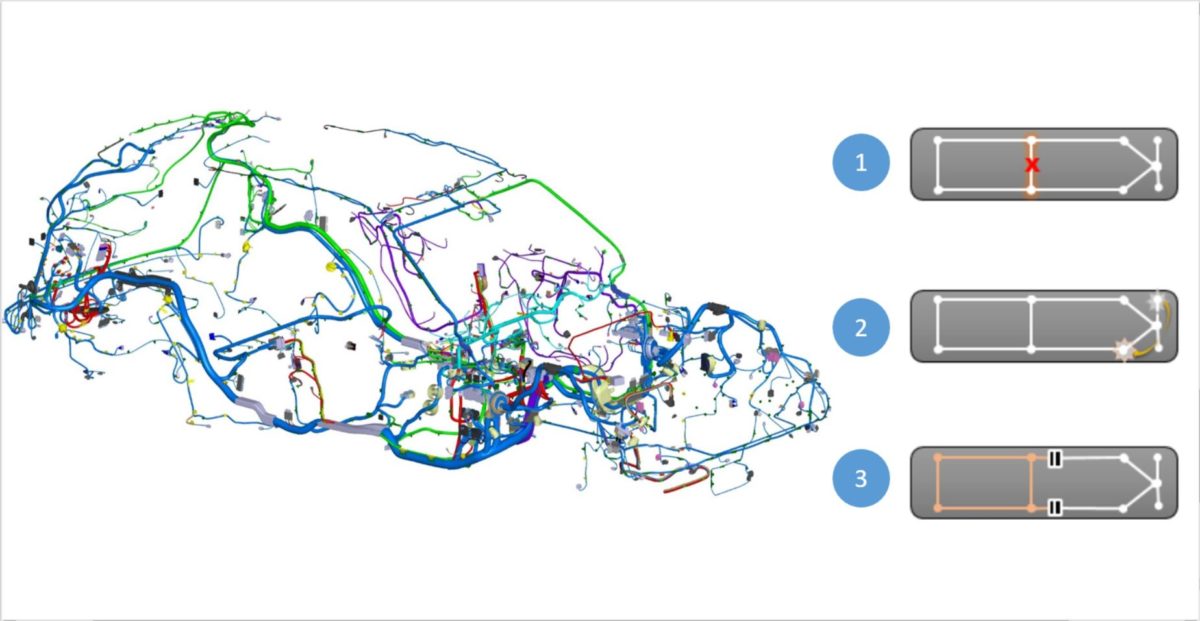

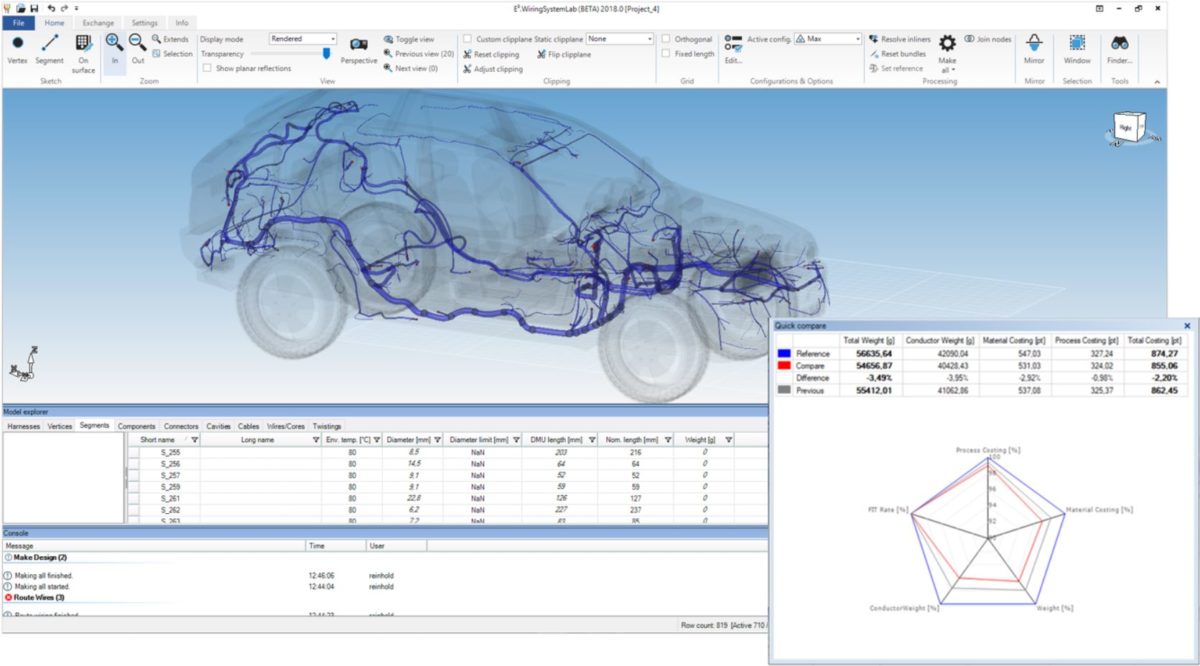

E3.WiringSystemLab merges designs from heterogeneous sources and provides comprehensive design exploration and optimization capabilities in 3D

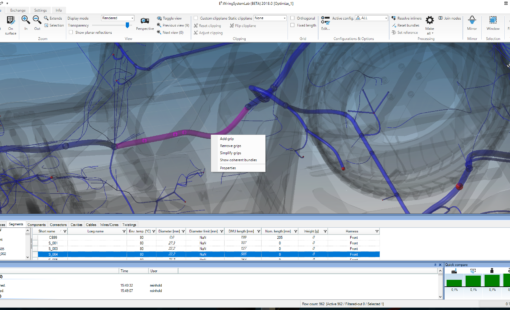

February 28, 2019 – Munich, Germany and Westford, MA, USA – Zuken introduces E3.WiringSystemLab, a new software solution that enables the optimization of complex wire harness designs based on inputs from heterogeneous sources. The product can import connectivity information from a broad range of sources and consolidates them with 3D topology data. The resulting 3D topology can be evaluated and optimized in a consistent 3D environment that has been designed to support the needs of casual users without requiring specialized training. Specialized functionality tailored specifically to topology exploration provides the ability to create and evaluate different architectural concepts.

Connectivity data can be imported from E3.cable, as well as via industry standard formats such as KBL, VEC, PLMXML, or even generic Excel® files. Topology information is imported in the form of geometrical bundles defined in the MCAD systems like CATIA®, NX® or Creo®. Based on these inputs, E3.WiringSystemLab provides the ability to host the complete wire harness optimization process within in a consistent 3D environment. Comprehensive modifications can be applied to the imported harness, including changes of packaging, partitioning into sub-harnesses and insertion of new routing pathways.

“Optimizing wire harness designs to meet targeted weight and cost objectives is a complex and challenging task”, comments Reinhold Blank, Zuken Business Director for Automotive & Transportation. “In particular, the preparation of data that typically involves a laborious flattening to 2D has been a huge time sink for the industry. With E3.WiringSystemLab we are providing a solution that revolutionizes the import and consolidation of data sources from different origins and supports wiring system experts to optimize their complex designs in a modern 3D environment.“

With its generic cost and weight evaluation and exploration capabilities, Zuken’s E3.WiringSystemLab achieves a substantial reduction of ramp-up and optimization cycles for wiring harness engineers.

Zuken’s new harness topology optimization E3.WiringSystemLab will be presented at the following events:

- USA: Zuken Innovation World Americas

Hilton Head, SC, April 15 – 17, 2019

- Europe: Automotive Wire Harness Conference,

Ludwigsburg, Germany, March 26–27

For more information, visit www.zuken.com/e3wslab

Related stories

- Products

E3.WiringSystemLab permet l'optimisation des faisceaux de câbles avec un degré de rapidité et de précision sans précédent. Avec ces capacités, il génère de considérables avantages à travers un large spectre d'applications dans l'industrie automobile et des transports.

- Products

E3.series facilite un processus de conception et de fabrication efficace et précis pour la planification électrique et fluidique, la planification de câbles et la disposition de faisceaux de câbles et d’armoires.