Create comprehensive manufacturing documentation

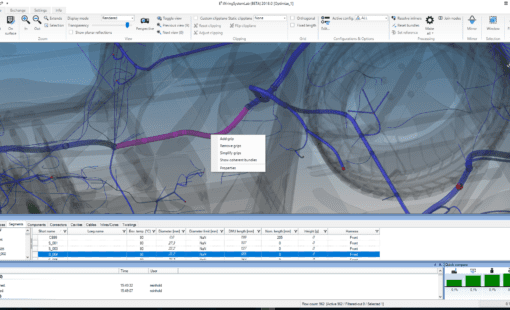

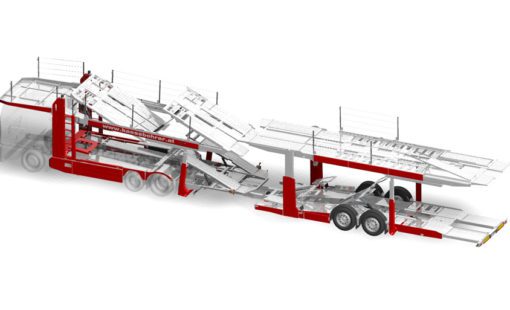

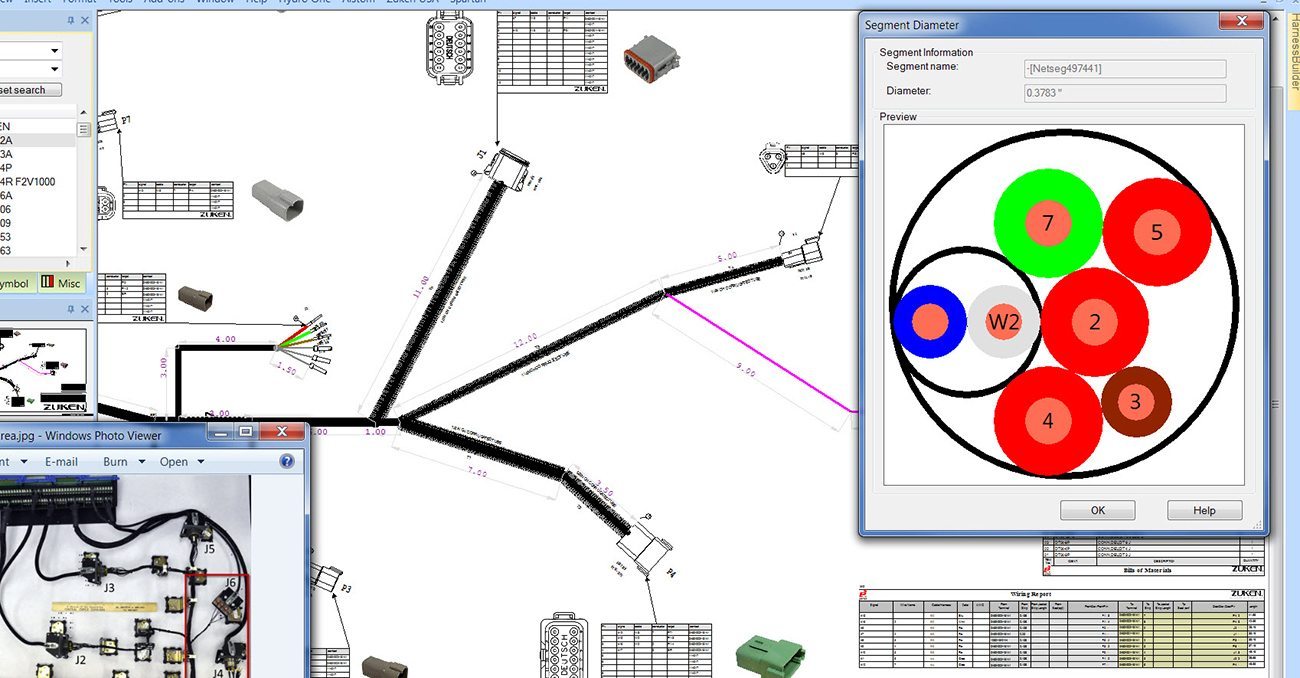

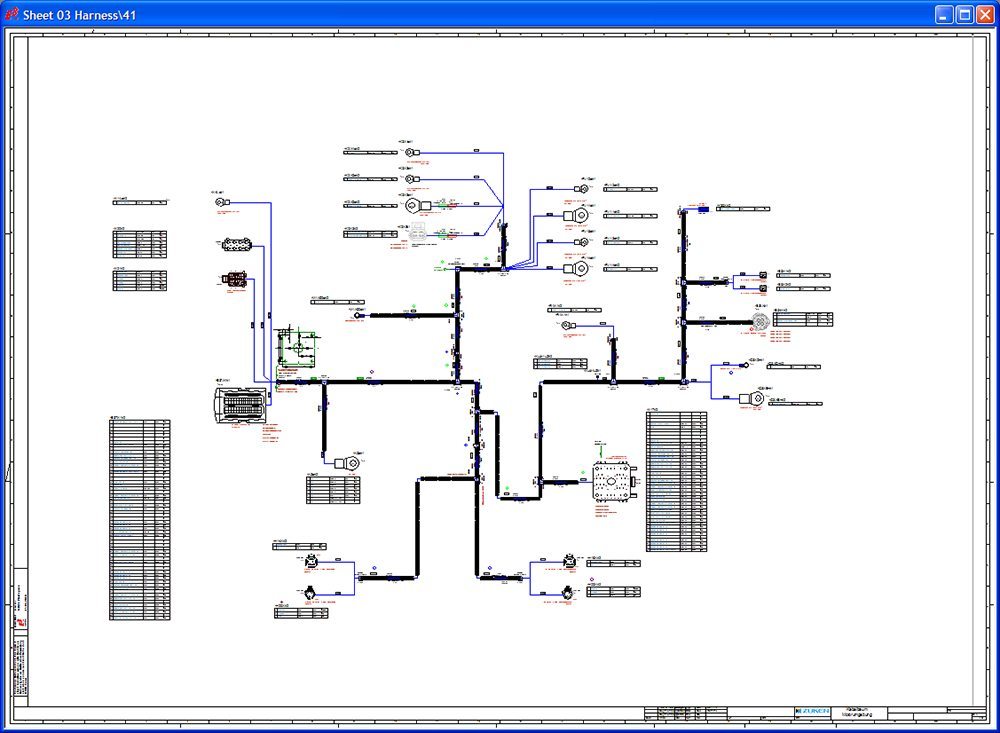

E3.formboard is a complete solution for creating cable harness drawings for manufacturing. On any sheet size, one or more manufacturing drawings can be created. Automatic functionality makes the placement, arrangement and dimensioning of the harness and its segments easier. E3.formboard is fully integrated with E3.cable. The logical interconnection data defined in E3.cable is used directly in E3.formboard, and any changes made in either module are automatically reflected.

Create comprehensive manufacturing documentation

Automatic calculation of wire lenghts and bundle diameters

Dynamic connector tables with pin, wire, cable, signal, gauge, color, and target information

Control and adjustment of wire lenghts

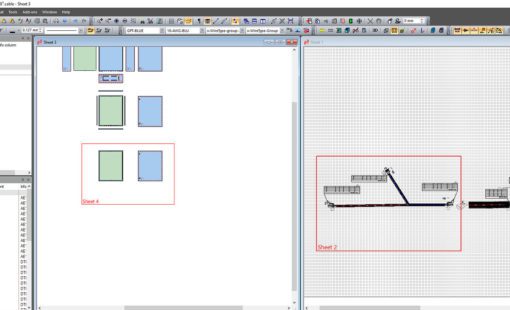

Formboard designs include connection tables, clips, heat-shrink, and convolute. Wire lengths are automatically determined and a packing algorithm calculates the outside diameter of the harness segments. To fit to paper size, wire harness branches are rotated about any point and special print functionality allows individual sections to be reprinted.

Connectors added to the harness sheet automatically include connection tables, while connect lines added between the connectors define the branches of the harness. Wires added to the pins in the connection tables are automatically routed through the shortest or pre-defined harness segments.

With E3.formboard’s integration with E3.cable, the logical interconnection data defined in E3.cable is used directly in E3.formboard. Any changes made in either module are automatically reflected in the other.

E3.formboard provides a complete solution for creating cable harness drawings for manufacturing

E3.formboard drawings provide a view of the cables and harnesses as defined in the schematic diagram.They comprise both electrical and non-electrical components including connector placement, wire segments, protective coverings, clips, labels etc.

Wire lengths are automatically determined and a packing algorithm calculates the outside diameter of the harness segments. To fit to paper size, harness branches can be rotated about any point and special print functionality allows individual sections to be reprinted

Configurable connector tables can be placed in the drawing to display pin, wire, cable, signal, gauge, color, and target information. These tables are dynamic, meaning that a wire can be added to a pin displayed in the table and connected to a pin in another table and Formboard will automatically route the wire from pin to pin through the harness segments.

Harness segments can be highlighted when the length displayed on the sheet does not correspond to the manufacturing length defined for each segment. These ‘out-of-scale’ segments can be automatically adjusted to display the correct manufacturing length assigned to the segments of the harness.

E3.formboard is fully integrated with E3.cable. The logical interconnection data defined in E3.cable is used directly in E3.formboard and any changes made in either module are automatically reflected in the other.

Manufacturing data can be extracted from the design in the form of wire lists, which include route and length information. Modules interface E3.panel to manufacturing equipment such as Komax wire preparation machinery and Perforex drilling, punching, and cutting tools.

Related Products

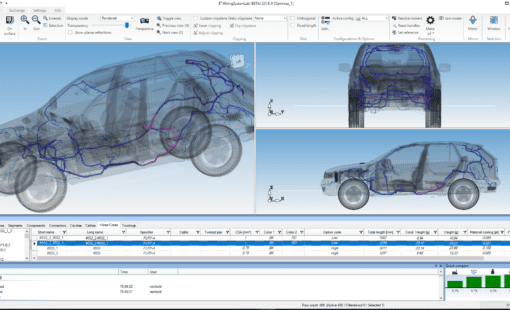

E3.WiringSystemLab enables the optimization of wire harnesses with an unprecedented degree of speed and accuracy. With these capabilities, it generates substantial benefits across a wide spectrum of applications in the automotive and transportation industry.

Sharing comprehensive harness design models and documents with internal or external project teams.

Related Resources

Find out more about manufacturing documentation creation via our webinars, press releases and more...

Today's discussions about the digital twin are mainly focused on the areas engineering and production. What is often overlooked is on-site maintenance and customer service.

This webinar follows our first webinar “Wire Harness Design Automation Basics I” where we have seen the logical part of the design process. Now we will look at the physical part of the wire harness design process.

The Austrian manufacturer of vehicle Transporters, Kässbohrer Transport Technik, achieved a substantial improvement in process reliability in the generation of individualized assembly instructions and schematic documentation by implementing E3.series. Turnaround cycles for special projects were reduced by 60 to 90%.

Specialist fire rescue and emergency vehicle manufacturer, Emergency One UK Ltd, uses E3.series software for its electrical harness design. This has enabled the company to produce wire harnesses to standardize the design and manufacturing process reaping, cost savings and reliability benefits, while also delivering flexibility through modular based customization.

After acquiring various companies around the globe in the 1990s, Alstom needed to integrate new elements into its international corporate structure in order to improve productivity and planning. This also meant creating a standardized software landscape that would cover all divisions of the group.

Mecalac designs and manufactures heavy plant vehicles for use in construction. Their vehicles – backhoe loaders, site dumpers and compaction rollers – are each offered in several variants. They all need to work in harsh environments.

Recent E3.formboard Blog Posts

E3.series with the shared sheet option for panels and formboard/nailboard makes it easy to design a large system and we will be looking at the quick steps needed to get started.

Feeling a bit dazed by the multitude of electrical applications available to you? With Zuken’s E3.series containing a host of products including E³.schematic, E³.fluid, E³.cable, E³.formboard, E³.panel, E³.RoutingBridge, E³.PLCBridge and E³.Wiring Diagram Generator, you may feel overwhelmed on your first approach.

Today I’m going to take a look at the functionality within E3.series that allows you to integrate with MCAD systems including Creo, CATIA and NX, to define cable lengths and harness structures. You can also watch a movie that shows how this is done in real life – transferring data back and forth from E3.schematic to Creo Parametric (aka ProE).

Hot on the heels of Racetech and Teepee Electrical, another autosport supplier has recently opted for E3.series to design their harnesses. I’d like to introduce HCI Systems and the man behind the operation, Mike Tickner. Why E3.series… and why now, was the basis of our chat last week.